Cutting Attachment

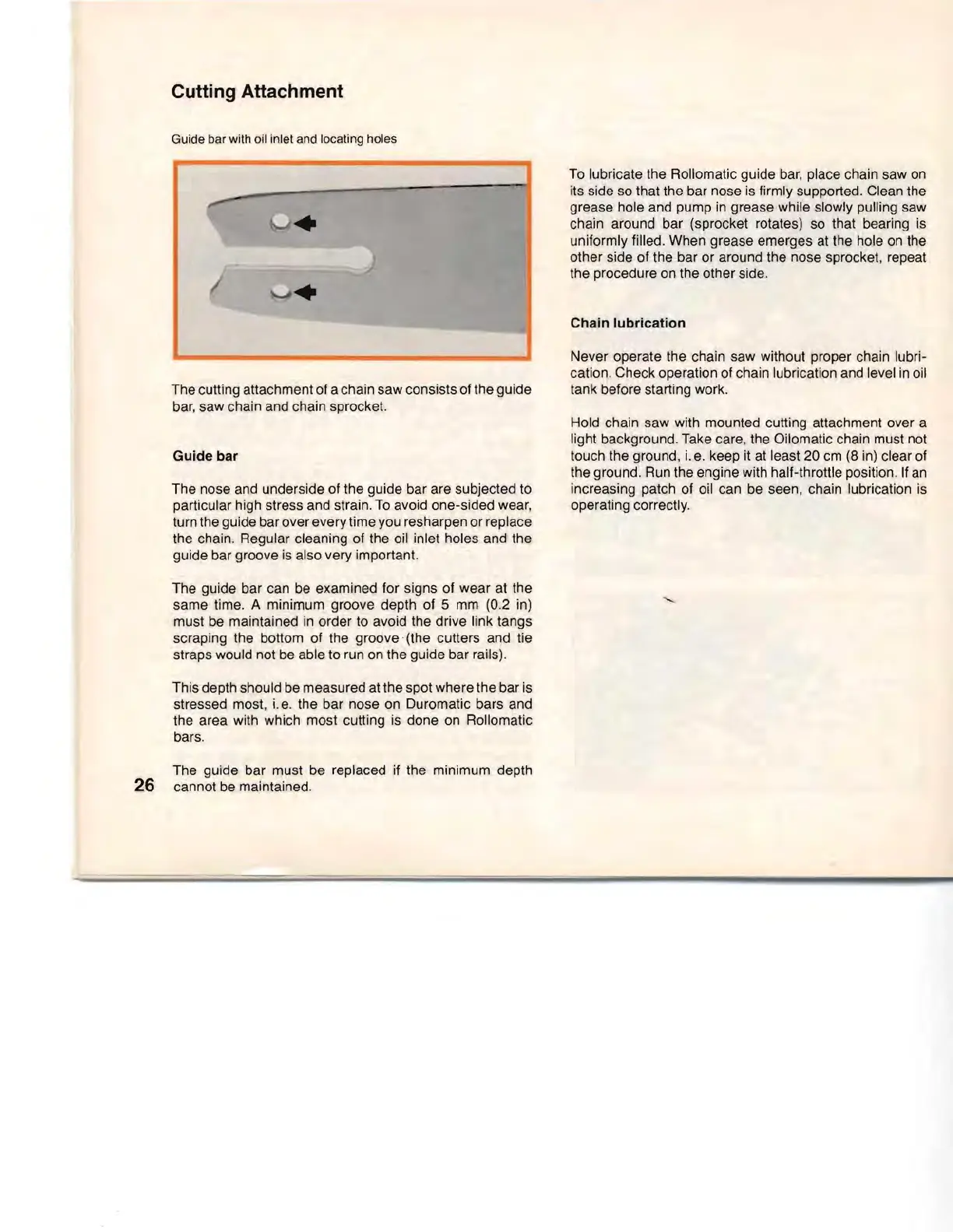

Guide bar with oil inlet and locating holes

The cutting attachment of a chain saw consists of the guide

bar,

saw chain and chain sprocket.

Guide bar

The nose and underside of the guide bar are subjected to

particular high stress and strain.

To

avoid one-sided wear,

turn the

gUide

bar over every time you resharpen or replace

the chain. Regular cleaning of the oil inlet holes and the

guide bar groove

is

also very important.

The guide bar can be examined for signs of wear

at

the

same time. A minimum groove depth of 5

mm

(0.2 in)

must

be

maintained in order to avoid the drive link tangs

scraping the bottom of the groove·(the cutters and tie

straps would not be able to run

on the guide bar rails).

This depth should

be

measured

at

the spot where the bar

is

stressed most,

i.

e.

the bar nose

on

Duromatic bars and

the area with which most cutting

is

done

on

Rollomatic

bars.

The guide bar must

be

replaced if the minimum depth

26 cannot

be

maintained.

To

lubricate the Rollomatic guide bar, place chain saw

on

its side so that the bar nose

is

firmly supported. Clean the

grease hole and pump

in

greasewhile slowly pulling saw

chain around bar (sprocket rotates)

so

that bearing

is

uniformly filled. When grease emerges

at

the hole

on

the

other side of the bar or around the nose sprocket, repeat

the procedure on the other side.

Chain lubrication

Never operate the chain saw without proper chain lubri-

cation. Check operation of chain lubrication and level

in

oil

tank before starting work.

Hold chain saw with mounted cutting attachment over a

light background. Take care, the Oilomatic chain must not

touch the ground,

i.

e.

keep

it

at

least 20

cm

(8

in)

clear of

the ground.

Run

the engine with half-throttle position.

If

an

increasing patch of oil can

be

seen, chain lubrication

is

operating correctly.

Loading...

Loading...