Replacing

the

chain

sprocket

On

machines with chain brake

The chain brake must be disengaged before the chain

sprocket cover can be removed - pull hand guard back

toward handlebar.

First remove chain sprocket cover and bar and chain.

Loosen and unscrew spark plug with combination wrench.

Put clutch wrench through the slots of the outer cover plate

between the clutch shoes. Turn crankshaft

in

such a way

that the boring provided

in

the handle of the clutch wrench

is

in

line with the bar stud and then insert the tube

1115

893

4200 through this boring onto the stud. Loosen crankshaft

nut with a ring wrench SW

19.

Attention! Crankshaft nut and carrier have left hand

thread

-loosen

in

clockwise direction!

After unscrewing the nut remove outer guide washer,

wrench and tube. Now screwlocking screw intothe cylinder

by hand until

it

has a snug fit. Turn crankshaft

in

clockwise

direction until the piston top rests against the locking nut,

loosen and unscrew carrier with clutch wrench.

Now the inner guide washer, chain sprocket, needle cage

and cover plate can be removed from the crankshaft.

Before reassembly clean

bull

end of crankshaft, wash

needle cage

in

clean gasoline and apply ball bearing

grease. Check drive pin

in

cover plate. If it is twisted insert

24 a new one; a worn out boring must be replaced.

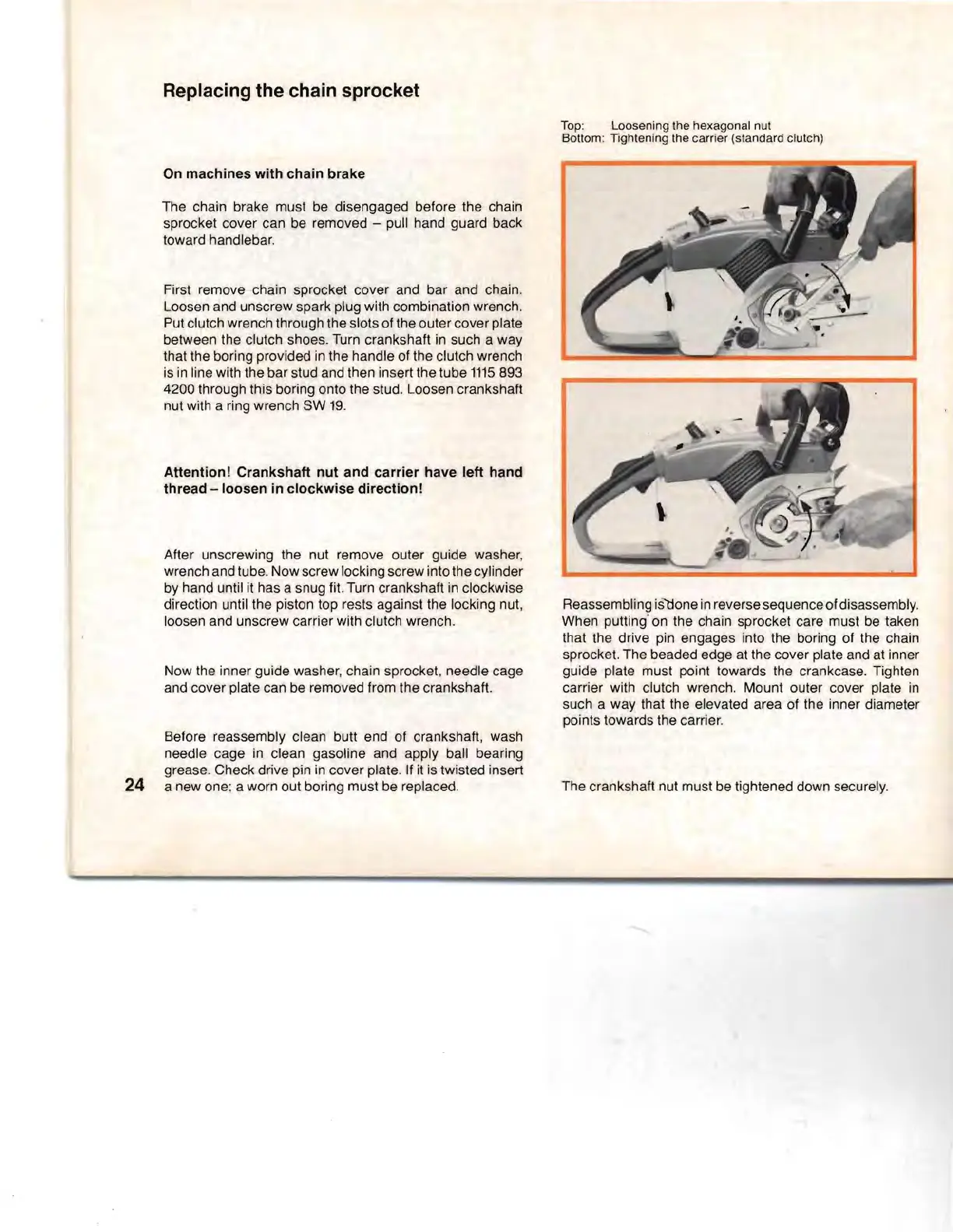

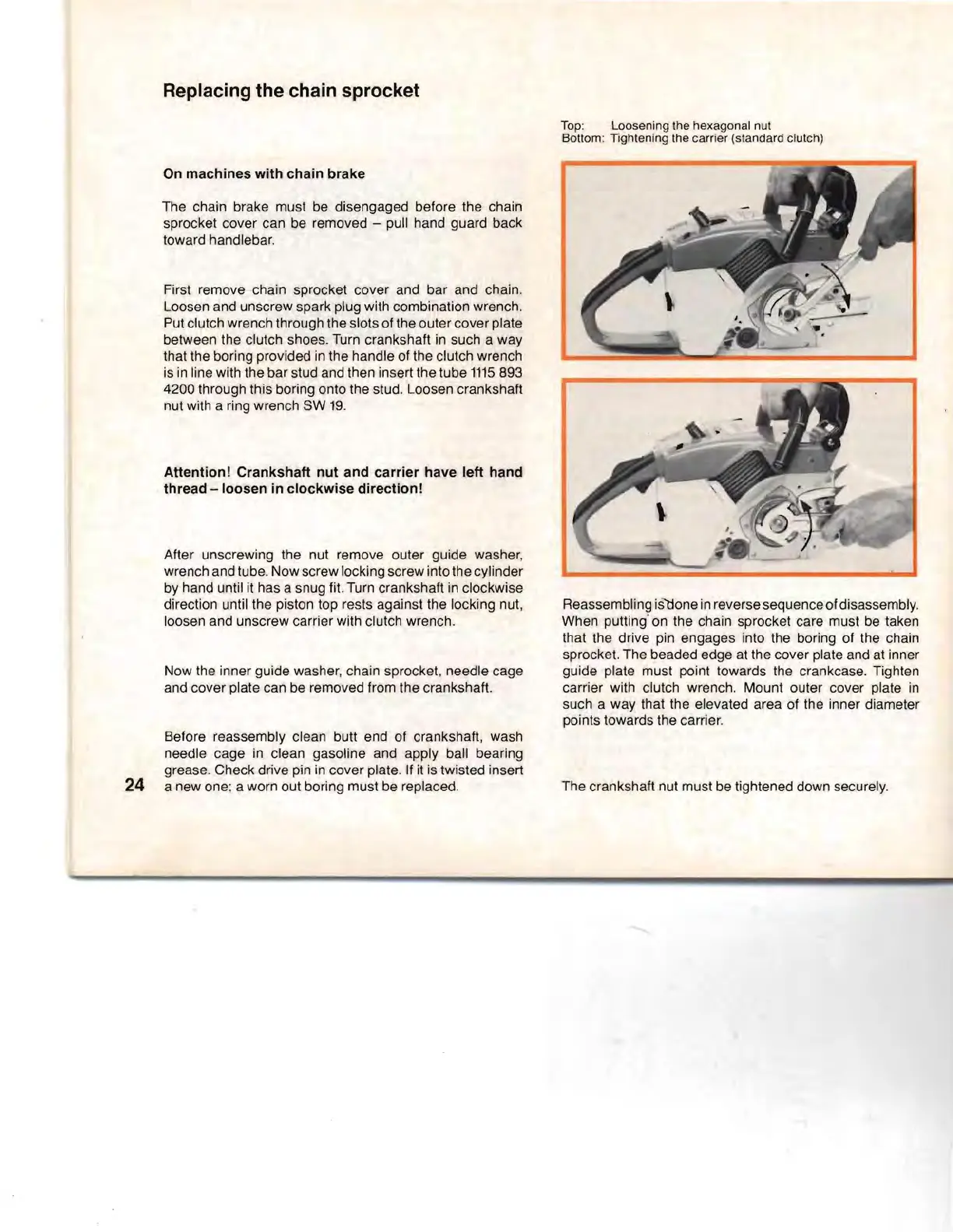

Top: Loosening the hexagonal nut

Bottom: Tightening the carrier (standard clutch)

Reassembling is1lone

in

reverse sequencea/disassembly.

W,hen

pulling' on the chain sprocket care must be taken

that the drive pin engages into the boring of the chain

sprocket. The beaded edge at the cover plate and at inner

guide plate must point towards the crankcase, Tighten

carrier with clutch wrench. Mount outer cover plate

in

such a way that the elevated area of the inner diameter

points towards the carrier.

The crankshaft nut must be tightened down securely,

Loading...

Loading...