39FS 120, FS 200, FS 250

English

Cutting tool rotates when engine is

idling

: Turn idle speed screw (LA) slowly

counterclockwise until cutting tool

stops rotating and then turn the

screw about another

1

/

2

to 1turn in

the same direction.

Erratic idling behavior, engine stops

even though setting of LA screw is

correct, poor acceleration

Idle setting too lean:

: Turn low speed screw (L)

counterclockwise (about

1

/

4

turn)

until the engine runs and

accelerates smoothly.

Erratic idling behavior

Idle setting too rich:

: Turn low speed screw (L) clockwise

(about

1

/

4

turn) until the engine runs

and accelerates smoothly.

Wrong fuel mix (too much engine oil in

the gasoline), a dirty air filter and

unfavorable running conditions (mostly

at part throttle etc.) affect the condition of

the spark plug. These factors cause

deposits to form on the insulator nose

which may result in trouble in operation.

If engine is down on power, difficult to

start or runs poorly at idling speed, first

check the spark plug.

: Remove spark plug as described

in chapter "Starting / Stopping the

Engine".

: Clean dirty spark plug.

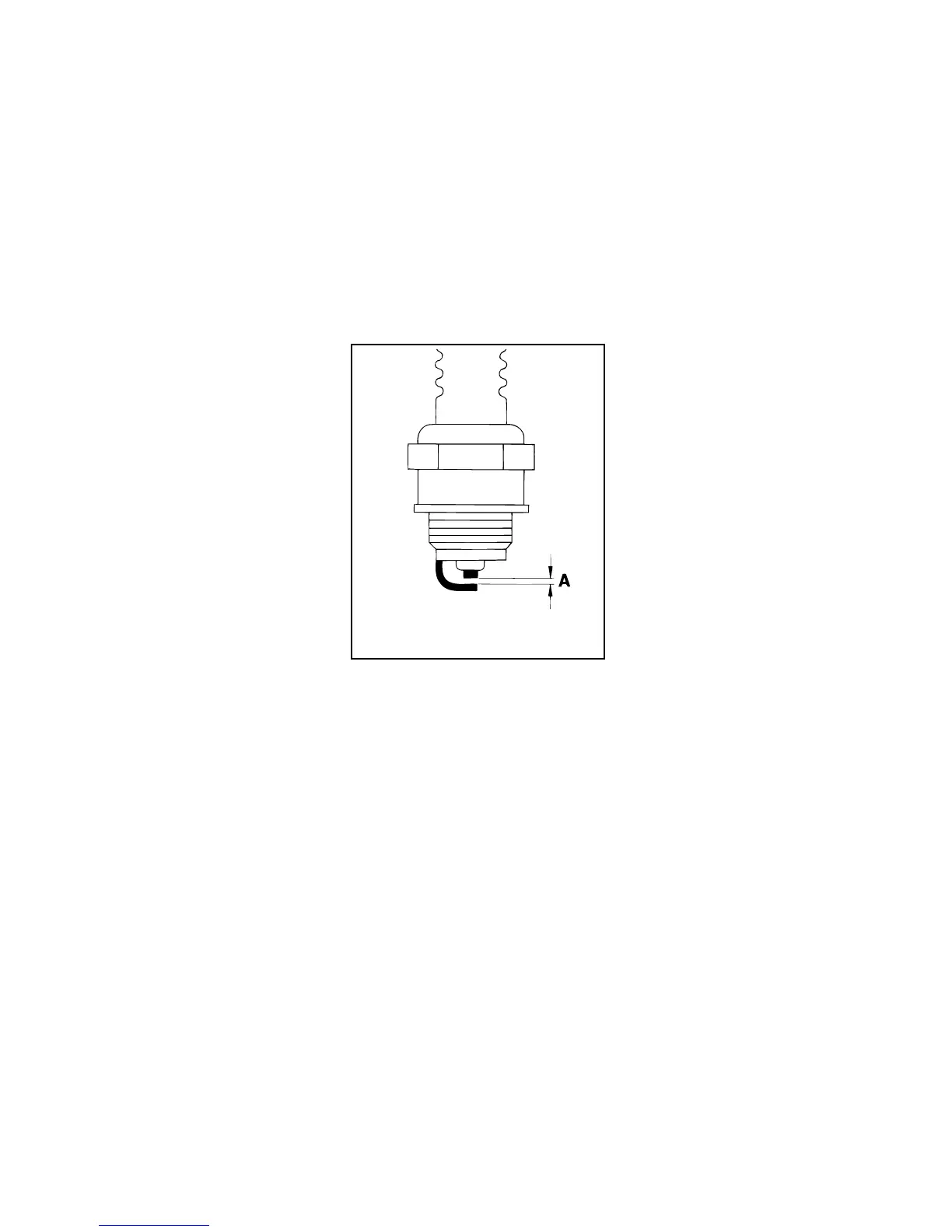

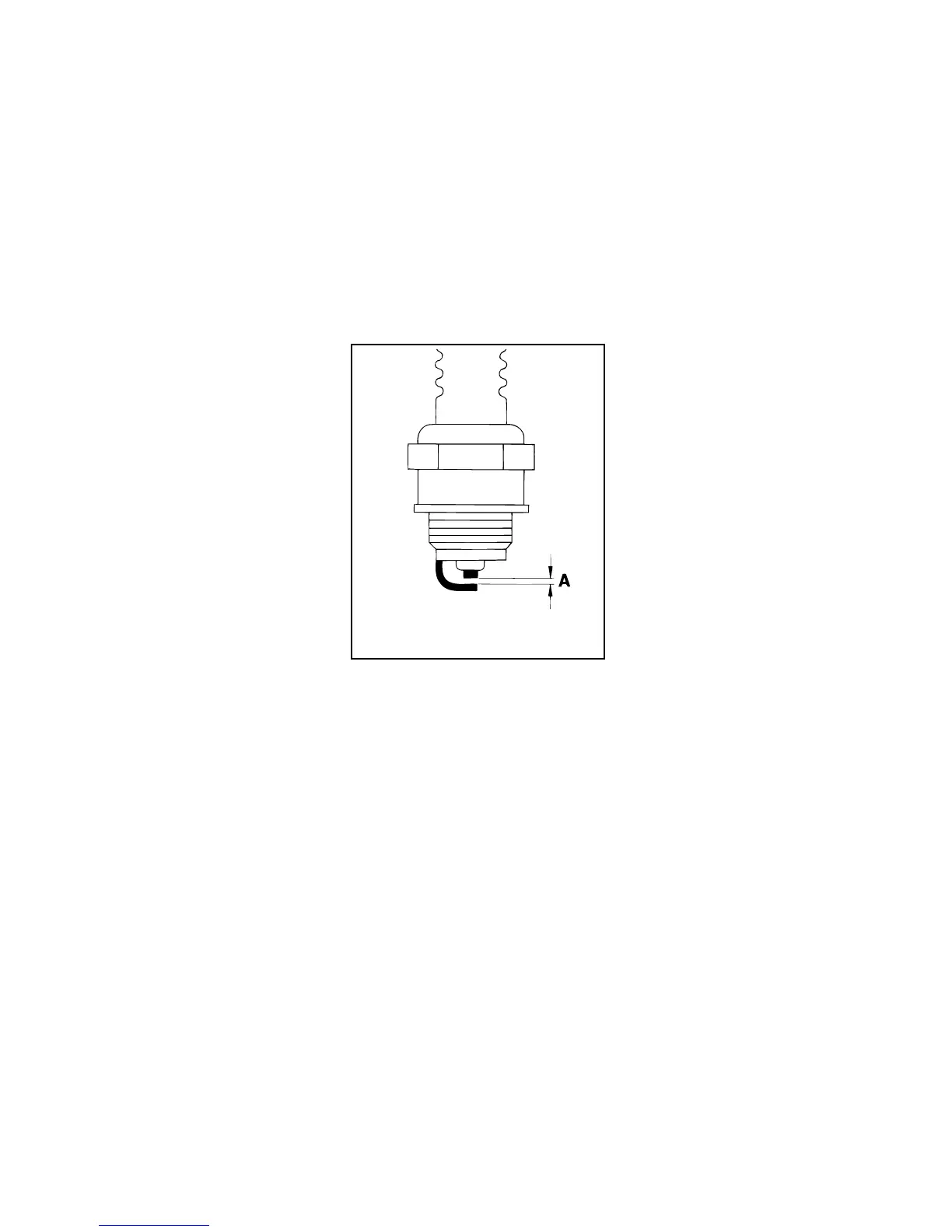

: Check the electrode gap (A) and

readjust if necessary – see

"Specifications".

: Use only resistor type spark plugs

of the approved range.

Rectify problems which have caused

fouling of spark plug:

: Too much oil in fuel mix.

: Dirty air filter.

: Unfavorable running conditions,

e.g. operating at part load.

Fit a new spark plug after approx.

100 operating hours

or earlier if the electrodes are badly

eroded.

Checking the Spark Plug

000BA002 KN

Loading...

Loading...