17 Taking Care of the Guide

Bar

► Turn the guide bar over – every time you

sharpen the chain and every time you replace

the chain – this helps avoid one-sided wear,

especially at the nose and underside of the

bar.

► Regularly clean the oil inlet hole (1), the oil‐

way (2) and the bar groove (3)

► Measure the groove depth – with the scale on

the filing gauge (special accessory) – in the

area used most for cutting

Chain type Chain pitch Minimum

groove

depth

Picco 1/4" P 4.0 mm

Rapid 1/4“ 4.0 mm

Picco 3/8" P 5.0 mm

Rapid 3/8“; 0.325“ 6.0 mm

Rapid 0.404“ 7.0 mm

If groove depth is less than specified:

► Replace the guide bar

The drive link tangs will otherwise scrape along

the bottom of the groove – the cutters and tie

straps will not ride on the bar rails.

18 Cleaning the Air Filter

18.1 If there is a noticeable loss of

engine power

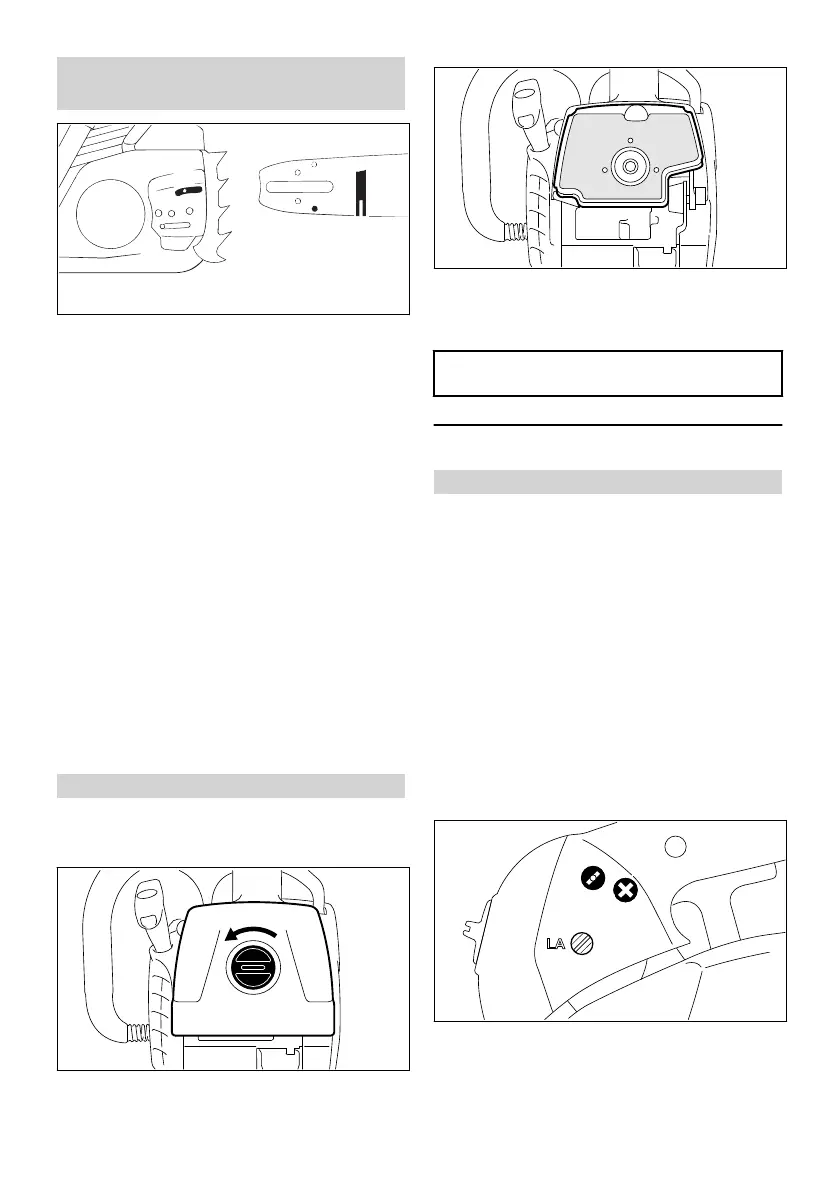

► Turn the twist lock 90° counterclockwise.

► Remove the shroud upwards.

► Remove the air filter upwards.

► Wash the filter in STIHL special cleaner (spe‐

cial accessory) or a clean, non-flammable sol‐

ution (e.g. warm soapy water) and then dry.

NOTICE

Do not use a brush to clean the filter.

Always replace a damaged filter.

19 Adjusting the Carburetor

19.1 General Information

The carburetor comes from the factory with a

standard setting.

This setting provides an optimum fuel-air mixture

under most operating conditions.

19.2 Preparations

► Shut off the engine.

► Check the air filter and clean or replace if nec‐

essary.

► Check the spark arresting screen (not in all

models, country-specific) in the muffler and

clean or replace if necessary.

19.3 Standard Setting

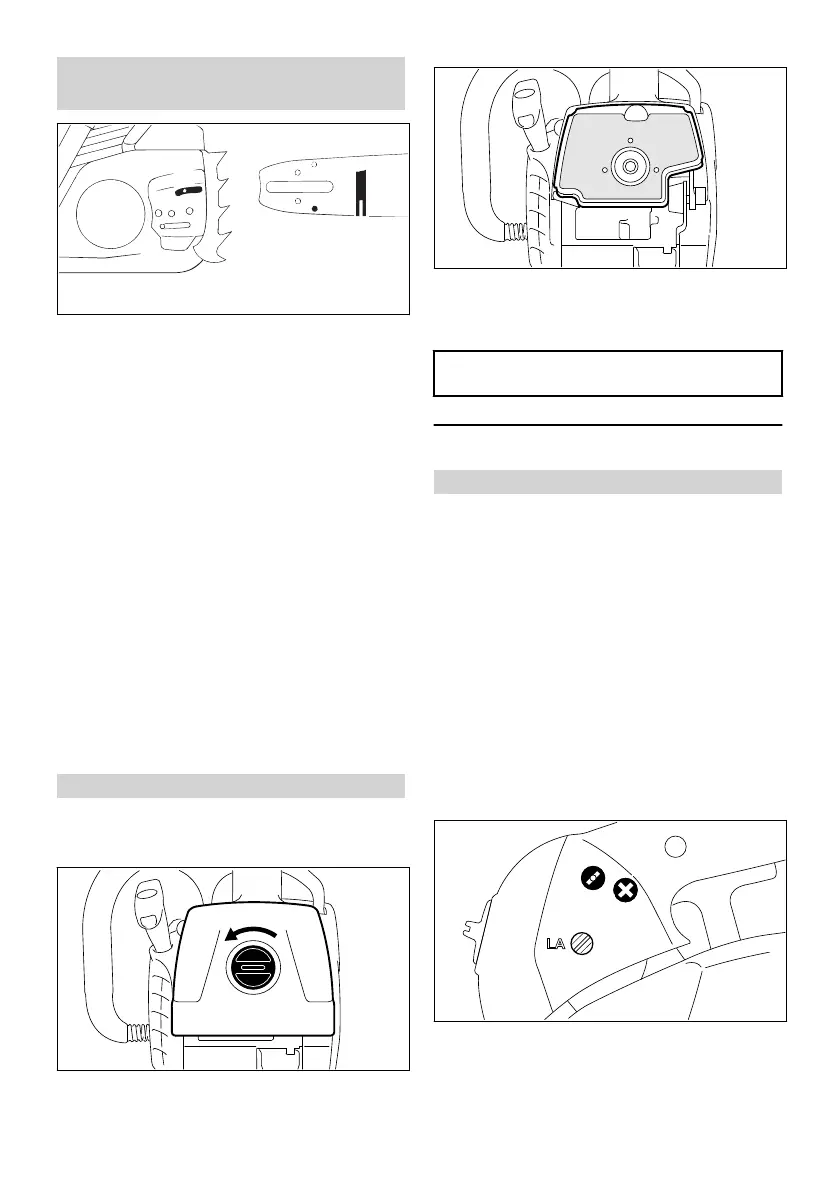

► Turn high speed screw (H) counterclockwise

as far as stop (no more than 3/4 turn).

► Turn the low speed screw (L) clockwise as far

as stop, then turn it back 1/4 turn.

17 Taking Care of the Guide Bar English

0458-508-8321-B 21

Loading...

Loading...