Order number: 900323.001 V1.74 Page 3

© Störk-Tronic 2021 • www.stoerk-tronic.com • Subject to modifications.

General information

GENERAL NOTES

The ST……112 controllers are designed for

general use in refrigerating plants.

Depending on the existing hardware, up to

four temperature sensors can be connect-

ed. These can either be used for captur-

ing the cold store temperature, evaporator

temperature, super-frost core temperature,

the temperature of a second control circuit

or the temperature of the condenser. The

type, function, offset and weighting of each

sensor can be configured separately via

parameters. Additionally, an analogue input

(4..20mA) can be made available for captur-

ing pressure levels, e.g. for condenser/fan

control, provided that the required hardware

is available.

The max. four digital inputs can also be con-

figured separately, depending on the hard-

ware installed. Possible functions include:

standby, door contact, high-pressure or

low-pressure switch.

Depending on the hardware, up to eight

relay outputs are possible the functions of

which can be configured as required via pa-

rameters. Please refer to the specifications

of the hardware installed to ensure that the

relays are not overloaded. Also refer to the

circuit diagram in the corresponding device

manual.

All parameters can also be accessed via

the RS485 interface. If an internal clock is

provided in the hardware, the corresponding

functions, e.g. defrosting or night-time in-

crease/decrease of setpoint, can be set and

started via parameters.

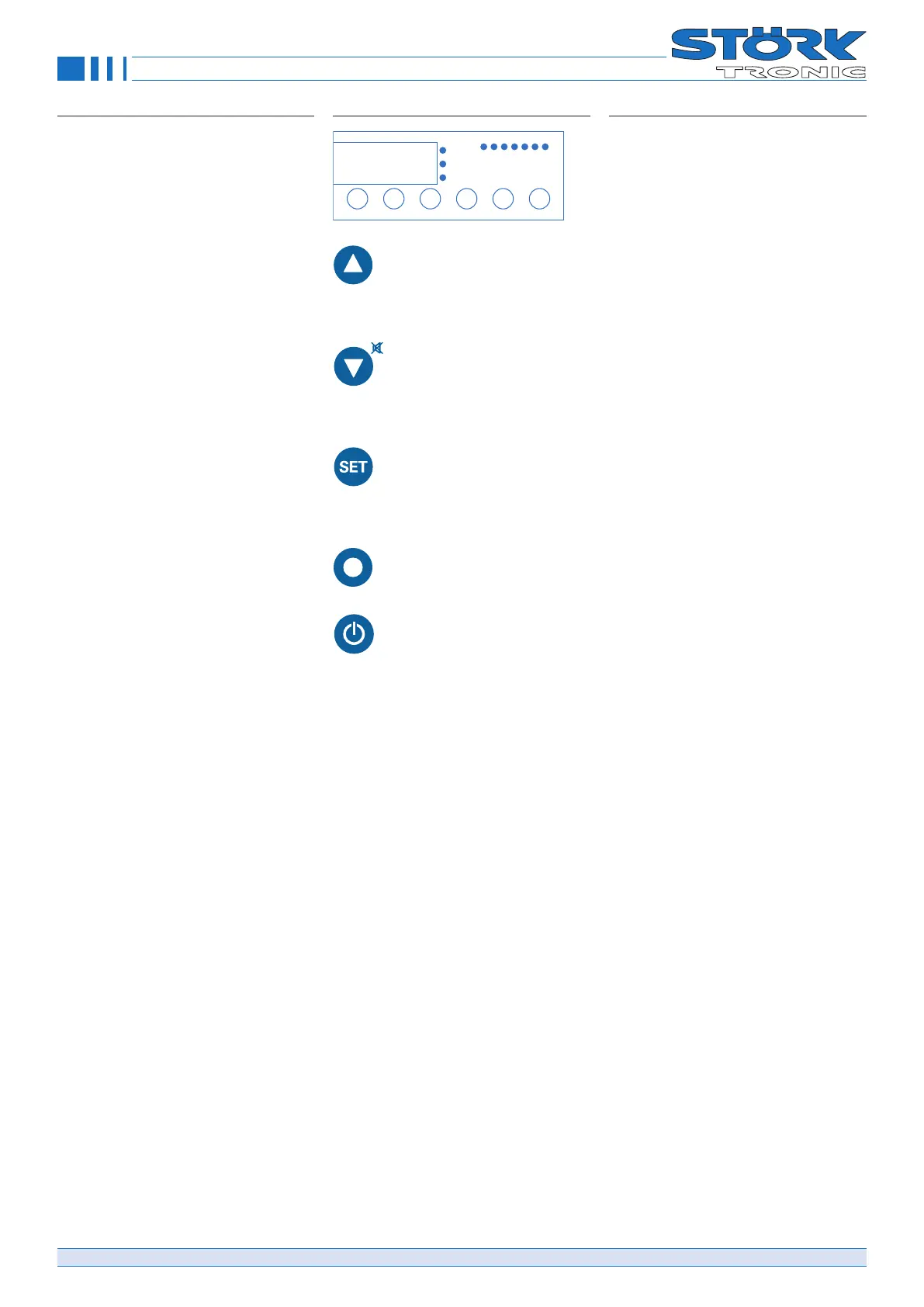

CONTROL KEYS

T1

1

2

3

45678910

T2 T3 T4 T5 T6

Key T1: UP

By pressing this key, the parameter

or parameter value is increased. A

further function of the key can be set with

parameter b1.

Key T2: DOWN

By pressing this key, the param-

eter or parameter value is de-

creased. A further function of the key can be

set with parameter b2.

Key T3: SET

While this key is pressed, the set-

point is indicated. The function of

the key can be set with parameter b3 (un-

changeable in this case)..

Key T5: function key

The function of the key can be set

with parameter b5.

Key T6: Standby

The function of the key can be set

with parameter b6. It is preset as

standby key. Thus the unit can be switched

on or off (no mains disconnection).

The cooling controller is generally controlled

using the buttons UP, DOWN and SET. The

standard display indicates the temperature

of the cold store (actual temperature value).

Press SET button to switch over the display

to the required cold store temperature (set-

point temperature).

The setpoint temperature can only be

changed by pressing buttons SET and UP

or SET and DOWN at the same time. While

pressing the buttons, the changing setpoint

temperature is displayed. After changing

the setpoint temperature and releasing the

buttons, the actual temperature is displayed

again. This is the standard setting method.

If you press the STANDBY button during op-

eration (for at least 3 seconds), the cooling

controller is switched off and the message

AUS will be displayed. To switch on the

controller again, press the STANDBY button

again.

In addition to setting the temperature value,

the buttons UP and DOWN perform other

functions, too. Pressing the UP for 3 sec-

onds will trigger a non-standard defrosting

operation of the refrigerating plant. In the

case of an alarm (with buzzer triggered), the

DOWN button can be used for acknowledg-

ing the buzzer sound.

PARAMETERISATION

Parameterisation of the cooling controller is

done in the factory or during commissioning

of a cold store by qualified staff. Wrong or

inappropriate parameterisation can result in

malfunction and damage of the refrigerated

goods. Parameter setting is possible only af-

ter entering one or more passwords. In the

following list of parameters, all parameters

of a complex cooling controller are listed.

Please note, however, that the parameters

listed are only available in controller designs

where the relevant hardware (outputs, in-

puts, sensors and internal clock) is available.

Parameterisation is possible at any time. The

control operation is not interrupted during

parameterisation, but can have a direct in-

fluence on it. If no button is pressed for 2

minutes, the operation is stopped and the

actual value is displayed again.

To activate parameterisation mode, press

buttons UP and DOWN at the same time.

After approx. 3 seconds, the code word

ADR. will be displayed. Press UP or DOWN

to switch between code words PA and ADR.

All other settings / value specifications in

parameter setting mode are performed us-

ing the default value setting method, i.e.

pressing buttons SET and UP / DOWN at

the same time

.

Loading...

Loading...