3-11

#7013455 - Revision A - April, 2009

Electronic Control System

International W

International W

ine Storage

ine Storage

(ICBWS)

(ICBWS)

Series

Series

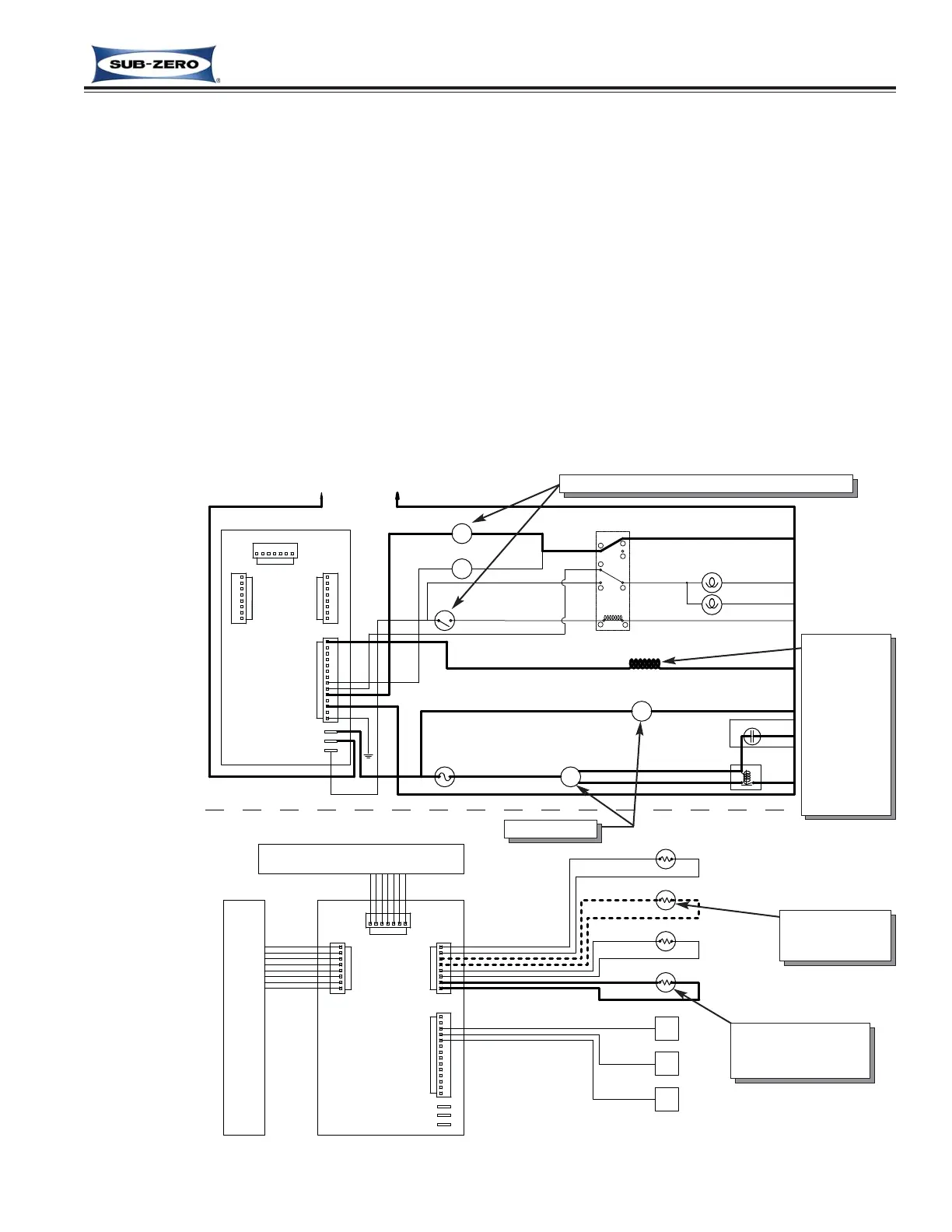

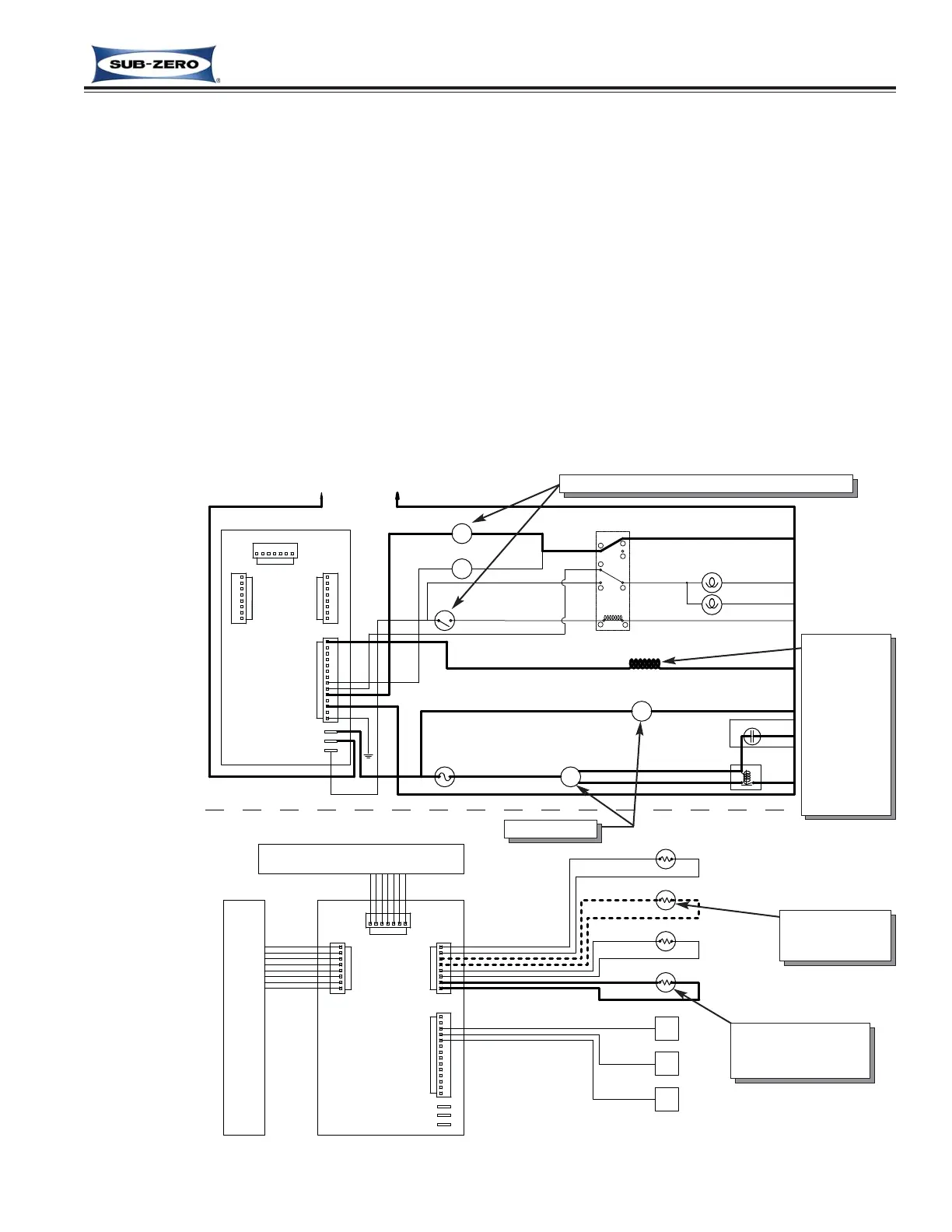

Figure 3-17. Cooling Signal Trace (Upper Evaporator at High-Offset Temperature, Calling for Cooling)

Control Compressor, Condenser Fan, Dual Refrigerant Valve and Evaporator Fan Motors

The control senses evaporator and compartment temperatures via thermistors; one on each evaporator, and one in

each compartment. High Offset (Cut-in) is governed by the evaporator temperatures; Low Offset (Cut-out) is gov-

erned by the compartment/zone temperatures. High Offset and Low Offset are based on the set-point.

If either evaporator temperature is at high offset (calling for cooling), power is supplied to the compressor and con-

denser fan motor, cycling them ON (See Figure 3-17).

Two relays on the control board, which are in series with one another, are used to control the dual refrigerant valve.

The first “pulse” relay controls the length of time the solenoid is energized (500ms / 30 pulses per 1/2 second). The

second “sine” relay controls the negative polarity, or positive polarity of the pulse supplied to the valve’s solenoid

(determined by which evaporator is calling for cooling, ( + ) = Upper Evaporator, ( - ) = Lower Evaporator). When an

evaporator calls for cooling, the bead inside the T-connection of the refrigerant valve is forced to one side or the

other, depending on the polarity of the pulse, supplying refrigerant to the appropriate evaporator (See Figure 3-17).

When the door is closed, the door switch is open, interrupting power to the relay coil, so the relay’s P1 to P5 con-

nection remains closed, keeping the neutral side of the evaporator fan motors circuits intact; depending on which

evaporator is calling for cooling, the corresponding evaporator fan relay on the control board closes, completing the

circuit and delivering power to the appropriate fan motor (See Figure 3-17).

NOTES:

• When in

Sabbath

Mode, the

evaporator

thermistors

still control

cut-in,

except

there is a

random fif-

teen (15) to

twenty-five

(25) second

delay

before

power is

supplied to

cooling

compo-

nents.

Loading...

Loading...