SECTION 6 ES-6 USER MANUAL

69

6.6 PARTS REPLACEMENT AND

ADJUSTMENT

PROCEDURES

FLUID FILTER REPLACEMENT

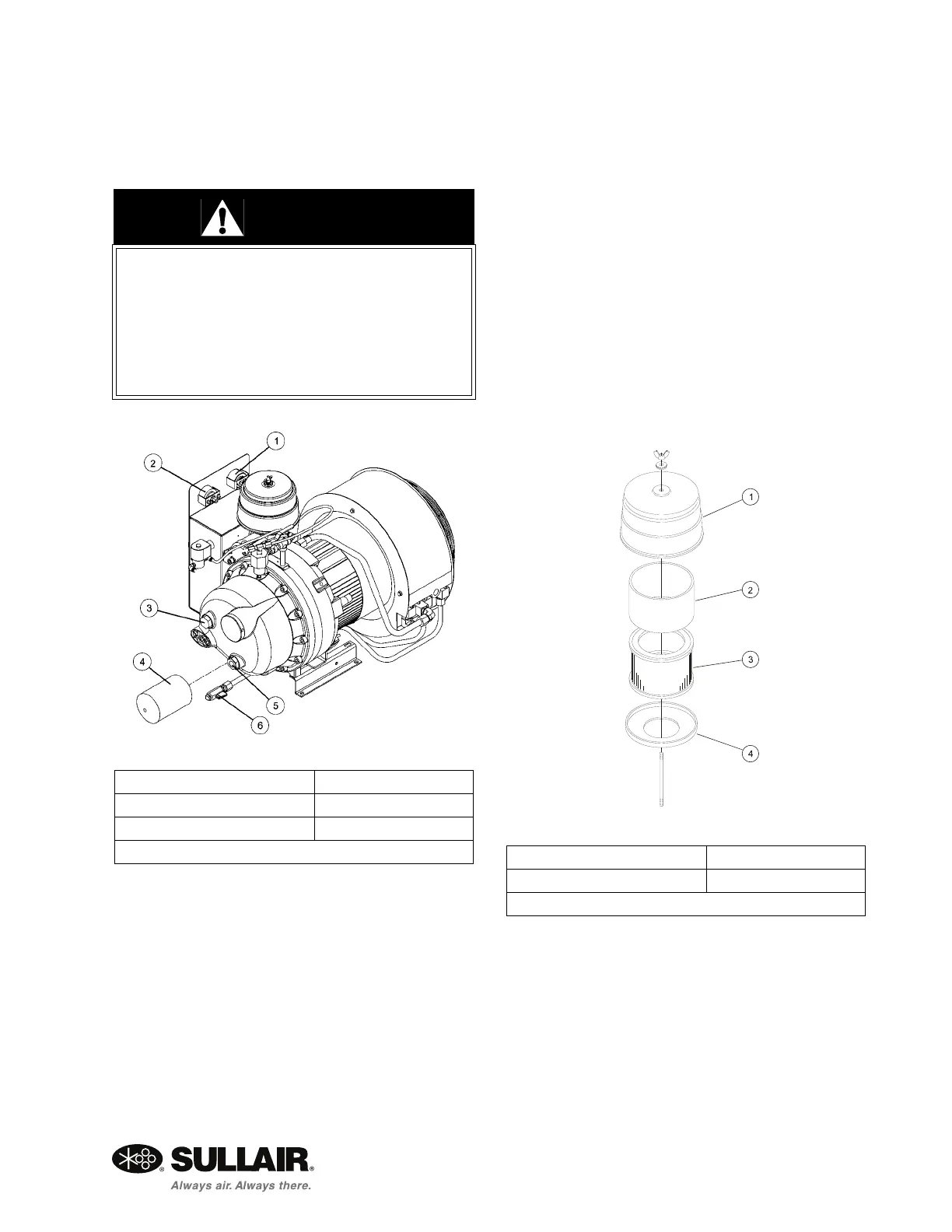

Refer to Figure 6-1. For maintenance schedule,

consult Table 3-7: Lubrication Guide.

1. To prevent spillage and loss of reusable fluid,

place a contaminate-free fluid receptacle

beneath fluid drain valve and fluid filter.

2. Drain fluid by removing fluid drain valve cap

at tee located beneath compressor (for com-

plete fluid change, drain fluid from cooler).

3. Using a strap wrench, remove the old ele-

ment and gasket.

4. Clean gasket seating surface.

5. Apply a light film of fluid to the new gasket.

6. Hand tighten new element until gasket is

seated.

7. Continue tightening element an additional 1/

2 to 3/4 turn.

8. Replace fluid. DO NOT OVERFILL.

9. Restart compressor and check for leaks.

A

IR FILTER MAINTENANCE

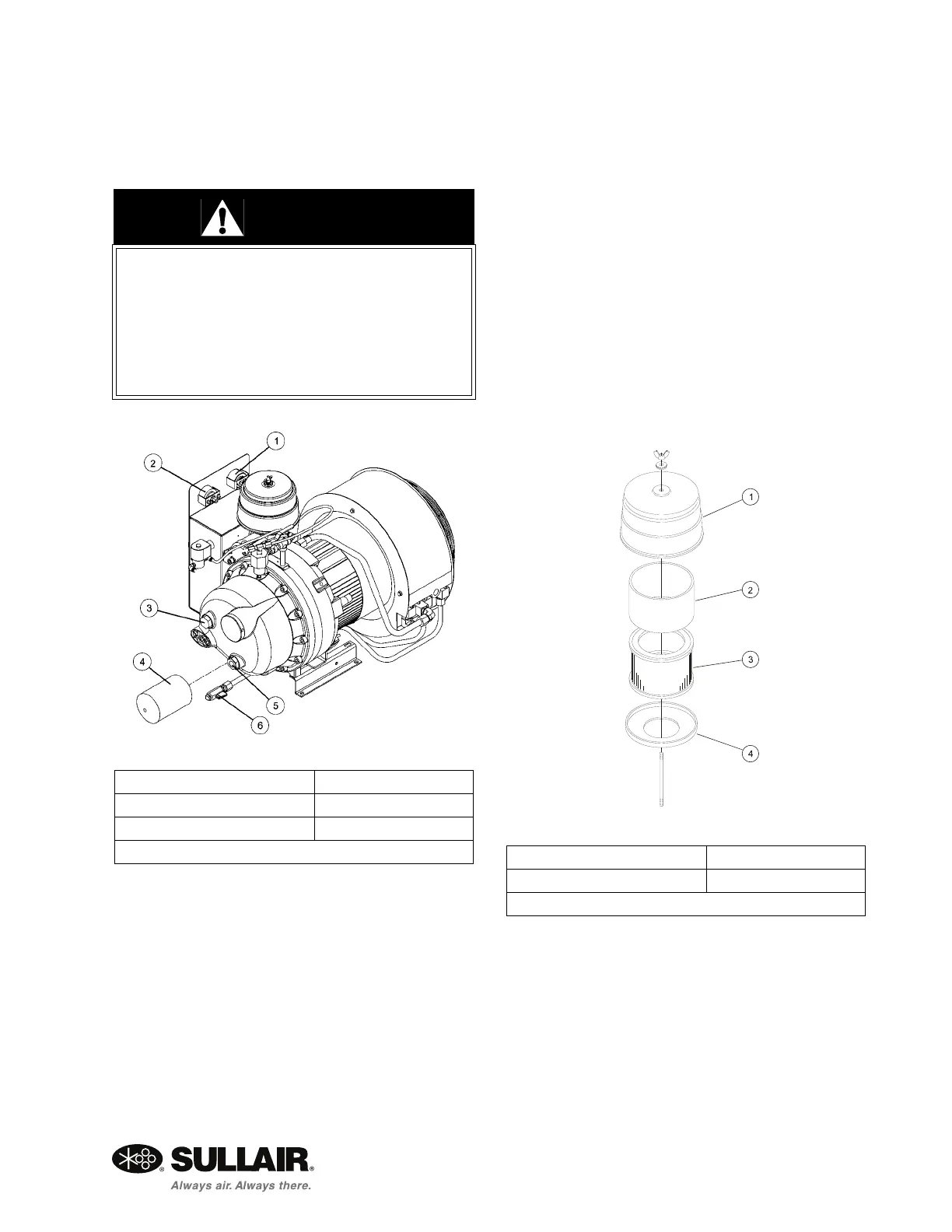

Refer to Figure 6-2. Air filter (P/N 02250111-680)

maintenance should be performed every six months

or more frequent if conditions so require.

WARNING

Before doing compressor maintenance,

disconnect compressor from power source

and lock out power source. Isolate

compressor from line pressure by closing

recommended discharge shut-off valve and

releasing all internal pressure

from compressor.

1. Pressure Gauge 2. Temperature Gauge

3. Fluid Fill Plug 4. Fluid Filter Element (I)

5. Sight Glass 6. Fluid Ball Valve

(I) Replacement Element Kit P/N 250028-032

Figure 6-1: Fluid Filter (P/N 250026-982)

1. Cover 2. Pre-Filter

3. Air Filter Element (I) 4. Base

(I) Replacement Element Kit P/N 02250111-804

Figure 6-2: Air Filter (P/N 02250111-680)

Loading...

Loading...