34

COMMON

Table 21 Approximate Amount of Grease Supply for Helical BUDDYBOX [g]

(4) Procedure for Supplying and Draining of Grease

Procedure for supplying grease for grease-lubricated models (excl. maintenance-free type)

1 Remove the grease discharge plug from the outside cover.

2 Supply grease with a grease gun from the grease nipple in the inside cover section or motor connection cover.

3 Attach the grease discharge plug.

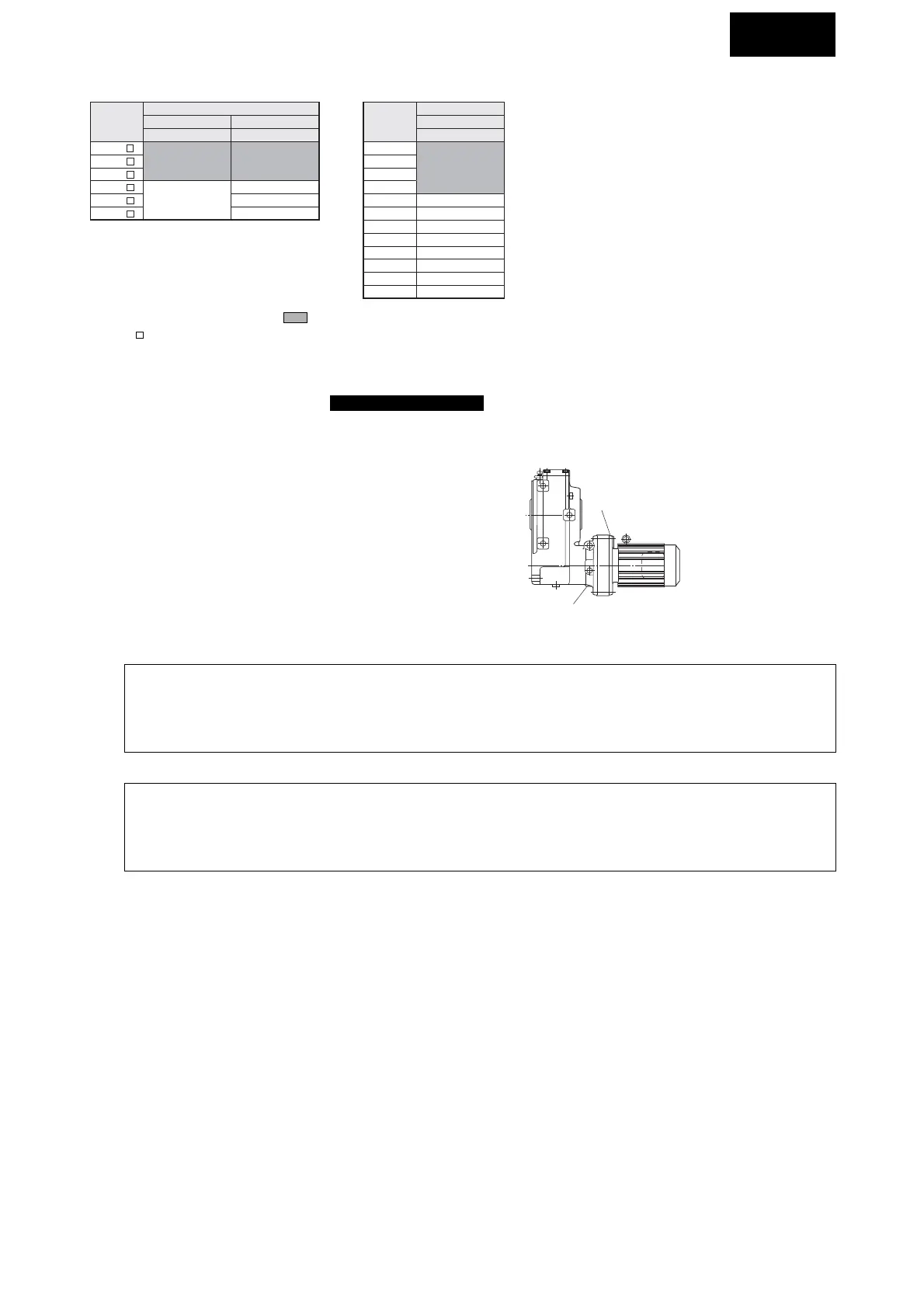

Fig.27 Position of Grease Drain Plug (Example: EHYM Type)

• Supply grease during operation to ensure proper, uniform circulation.

• Supply grease slowly.

• Do not supply grease more than the amount shown in Table 20 and 21. Grease temperature rise or grease leakage

to motor part because of agitation heat.

Grease Replacement of Grease-Lubricated and Maintenance-Free Models

Grease fitting

Grease drain plug

• The unit may be used for a long time safely, because long-lifetime grease is sealed in. However, overhaul every

20,000 hours or 3-5 years of operation ensures even longer lifetime.

• Always consult our specialized factory for overhaul of gearmotors and reducers. Experience is necessary for

overhaul.

Single Stage Type Double Stage Type

Size

Mounting Direction

Size

Mounting Direction

Y1,Y2,Y3,Y4 Y5,Y6 All of Direction

Input Side Input Side Input Side

Z609

Z609DA

A610

A610DA

B612

B612DA

C614

Oil Lubrication

150 ~ 225 B612DB

D616 250 ~ 375 C614DA 8.5 ~ 12.5

E617

335 ~ 500 C614DB 20~ 30

D616DA 20 ~ 30

D616DB 40 ~ 60

D616DC 85~ 125

E617DA 20 ~ 30

E617DB 40 ~ 60

E617DC 85 ~ 125

Note: • Because shaded section indicates Long-life grease models, they do not need to supply grease.

• indicates either 0 or 5.

• Refer to page 26-28 for approximate amount of oil supply for the part of oil lubrication.

Loading...

Loading...