32 Hyponic® Operating and Maintenance Manual

Hyponic® Operating and Maintenance Manual 33

www.SumitomoDrive.com

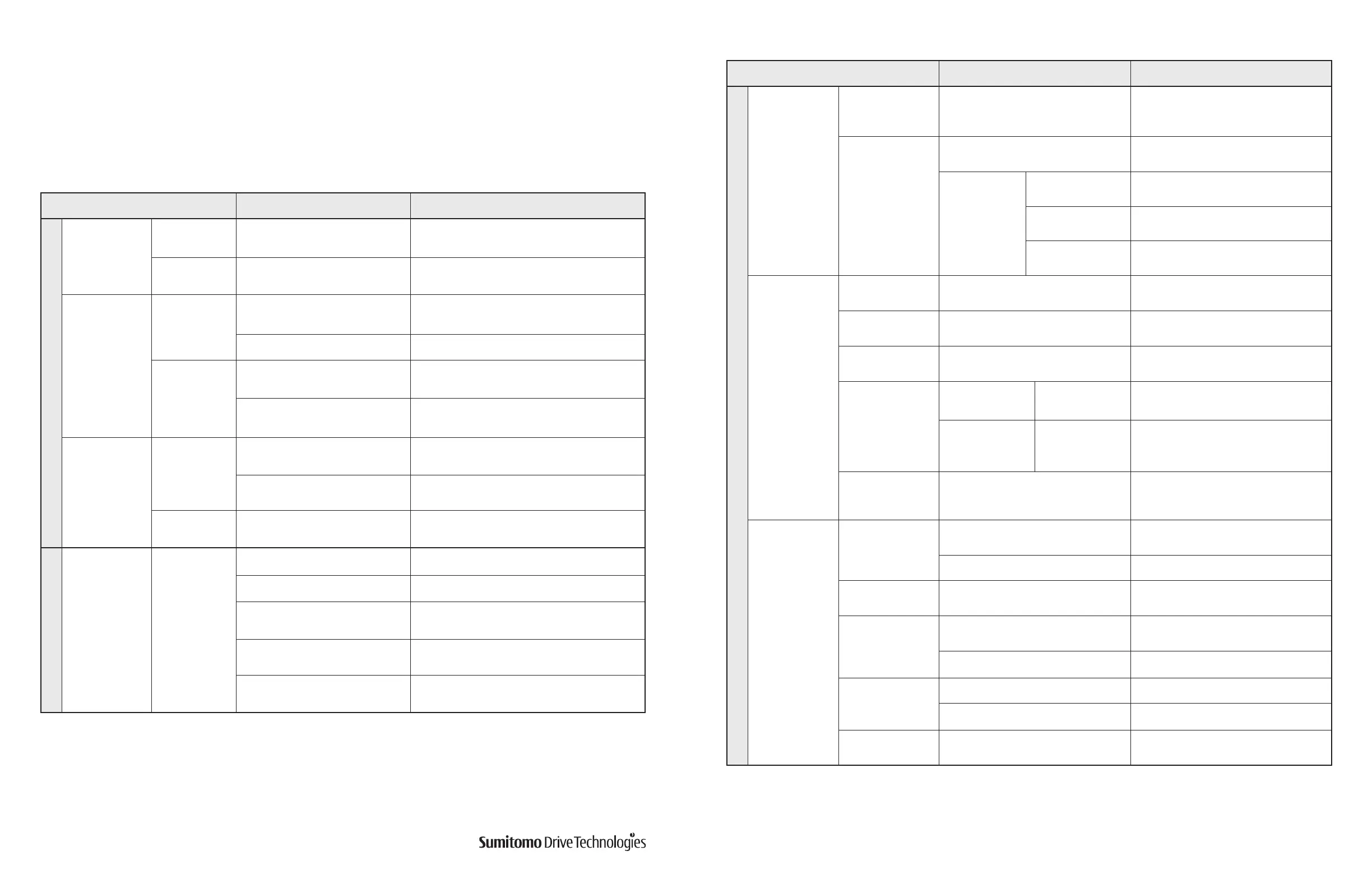

Troubleshooting

The Hyponic® unit is running normally when it meets the following criteria:

1) The motor begins to run immediately after the start switch is moved to the ON position.

2) The unit does not make any abnormal sounds during operation.

3) The motor stops running within about 0.5 seconds after power to the unit is switched off.

Problem Possible Cause Corrective Action

Runs Hot

Overloading

Load exceeds the capacity of the

Hyponic®

Check rated capacity of the Hyponic®; replace

with unit of sufficient capacity or reduce load.

Improper

lubrication

Wrong lubricant

Flush out and refill with correct lubricant as

recommeded.

Vibration or

noise

Loose

Foundation

bolts /

Torque Arm

Weak mounting structure

Inspect mounting of Hyponic®. Tighten loose

bolts and/or reinforce mounting structure.

Loose bolts Tighten bolts.

Failure of

bearings

May be due to lack of lubricant Replace unit.

Overload

Check rated capacity of Hyponic®, replace with

unit of sufficient capacity or reduce load.

Output shaft

does not turn

Motor shaft

broken

Overloading of reducer can cause

damage

Replace broken shaft. Check rated capacity of

Hyponic®.

Key missing or sheared off on

input shaft

Replace key.

Motor

doesn’t turn

Motor

Refer to Motor section of Troubleshooting

Guide.

Load is

disconnected

but motor

doesn’t rotate

Makes a

groaning

sound

Faulty switch contact Replace contact.

Blown fuse Replace.

One phase wire of the power

supply open

Replace.

Stator coil open

Repair by rewinding or replacing stator

assembly.

Stator and rotor touching due to

bearing housing wear

Replace the bearing and bracket.

Table 18. Quick Troubleshooting Guide

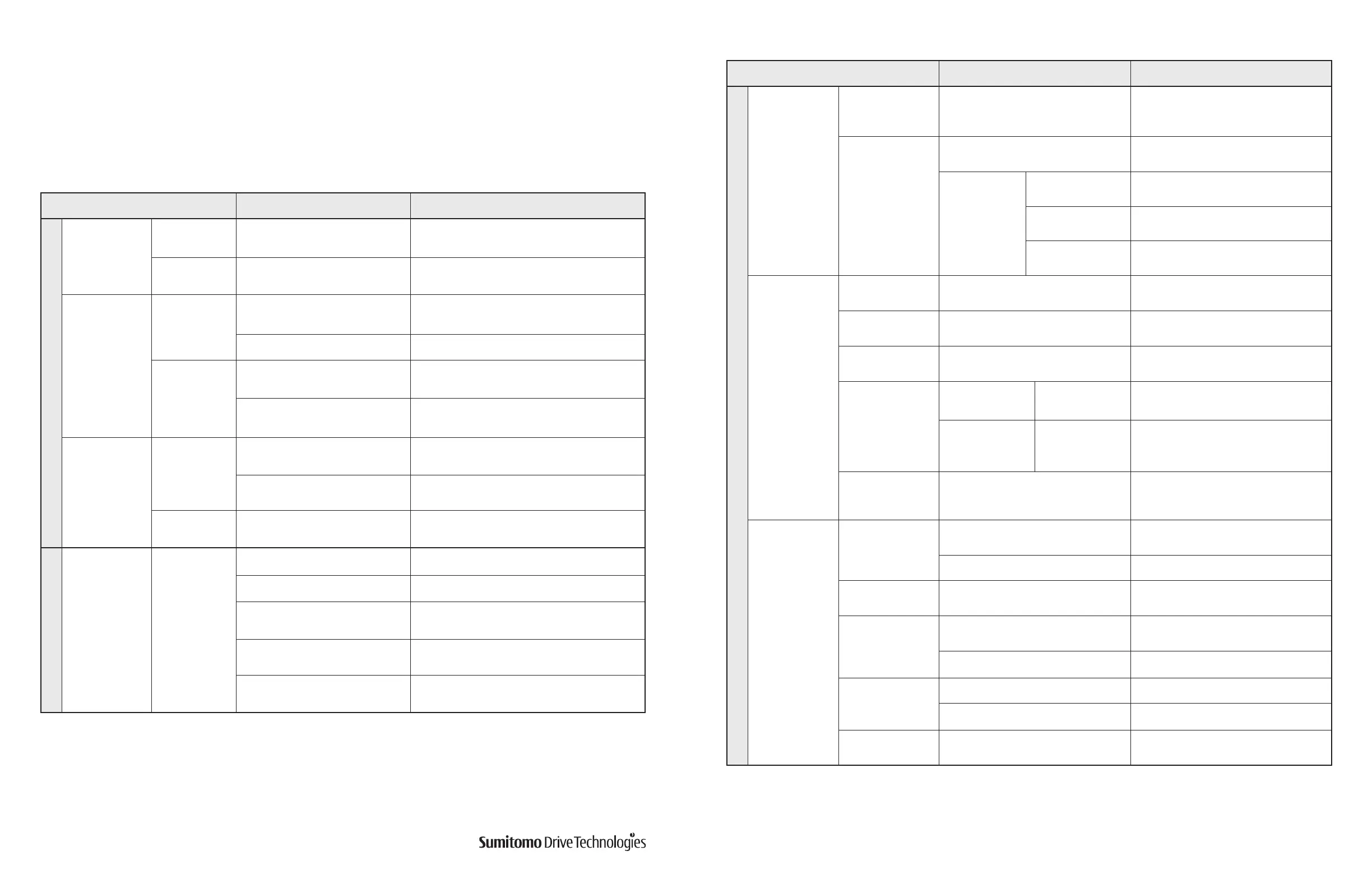

Problem Possible Cause Corrective Action

Load is

disconnected

but motor

doesn’t rotate

(cont.)

Starts in either

direction when

turned by hand

Three phase is operating as single-

phase

Check the power source with a

voltmeter.

Doesn’t make

any noise

Stator coil open

Repair by rewinding or replacing stator

assembly.

Outside the

motor

Power failure Contact the power company.

Open connection

wire

Check the source wiring.

Faulty starter

contact

Replace contact.

Rotates with

the load

disconnected,

but:

Rotates in the

wrong direction

Connection error

Change any two of the three-phase

source.

Fuse blows Shorted lead wire Replace.

Speed doesn’t

increase

Faulty starter contact Replace contact.

Groans

Overcurrent

Overheating

Rotor and

stator touching

Repair by winding or replacing stator

assembly.

Overcurrent

One phase

of stator coil

shorted

Replace the stator winding.

Makes a high

pitched metallic

noise

Faulty bearing Replace the bearing.

Rotates

when the

load is dis-

connected

but when

the load is

connected:

Switch

overheats

Insufficient switch capacity

Replace with one having the rated

capacity.

Overload Drop to the rated load.

Fuse blows Insufficient fuse capacity

Replace with one having the rated

capacity.

Overheats

Overload Drop to the rated load.

Voltage drop Consult with the power company.

Speed suddenly

drops

Voltage drop Consult with the power company.

Overload Drop to the rated load.

Stops Bearing damaged by overheat Replace the bearing.

Table 18. Quick Troubleshooting Guide (cont.)

HYPONIC®MOTOR

MOTOR (cont.)

Loading...

Loading...