2.17

SECTION 2 - SPRAYER OPERATION

A. For CLOSED CENTER LOAD SENSING tractors

adjust pump as follows:

1. Loosen jam nut for bypass screw located on top

of hydraulic motor and turn screw completely in.

2. Secure jam nut.

3. Adjust ow control valve for tractor hydraulic

system to allow minimum oil ow.

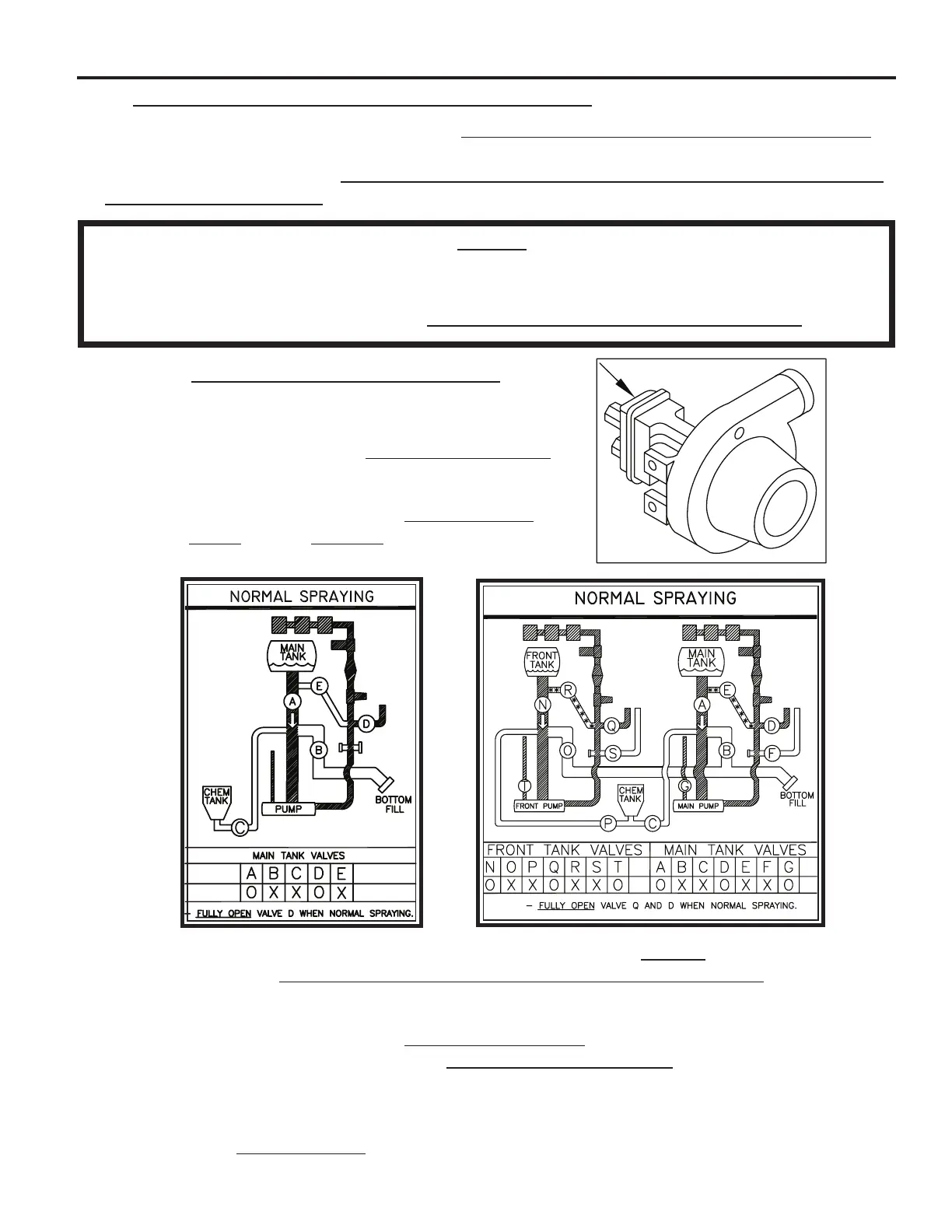

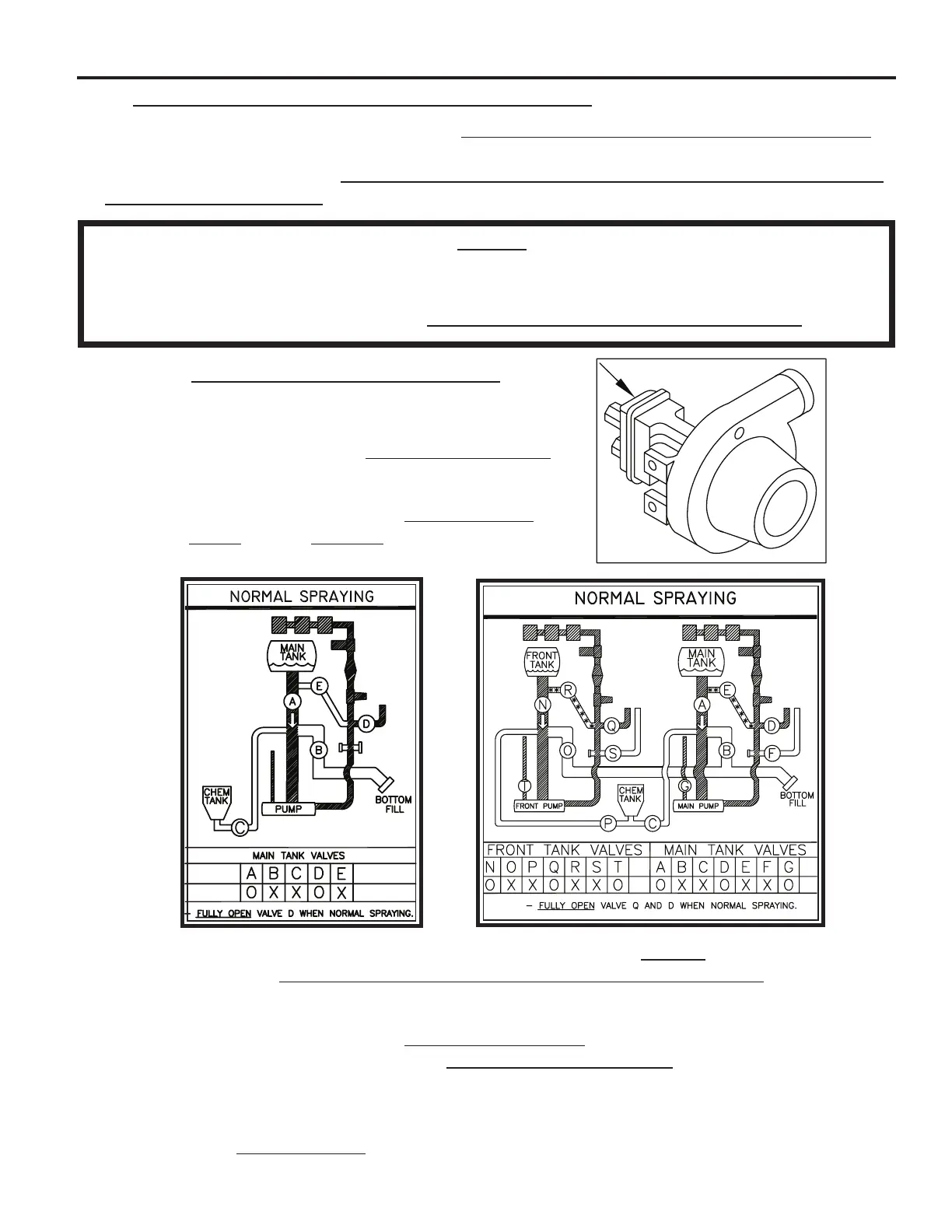

SINGLE TANK DUAL TANK

NOTE!

WHEN HIGH SPRAY PRESSURES ARE DESIRED, OPERATOR MUST ADJUST AGITATORS

TO INCREASE SPRAY PRESSURE. WITH ALL SPRAYER FUNCTIONS SHUT OFF AND

PUMP RUNNING AT FULL CAPACITY PRESSURE MUST NEVER EXCEED 125 PSI.

3. ADJUST HYDRAULICALLY DRIVEN PUMP SYSTEM

The hydraulically driven pump system must be adjusted to limit maximum shut off pressure of 125 psi

in order to stay within the 0 to 125 psi operating range of the plumbing system. Tractor hydraulic output

will affect pump performance. For more complete information see the Hypro pump selection guide

included in the publication.

4. Close manual valve D or Q (agitator control) plus make sure switches for all boom Electric

Ball Valves are off. LEAVE VALVES A AND N (TANK SUCTION) OPEN!

5. Engage tractor hydraulic system and increase to normal eld rpm speed.

6. Adjust ow control valve for tractor hydraulic system until pressure gauge reads 30-50 psi

over the expected spray pressure. DO NOT EXCEED 125 PSI.

7. Disengage tractor hydraulic system by moving lever to oat position. This will allow pump to

coast to a stop.

8. Set up Normal Spraying.

Loading...

Loading...