2.24

SECTION 2 - SPRAYER OPERATION

2.6 SPRAYER SYSTEM FIELD OPERATION AND ADJUSTMENT

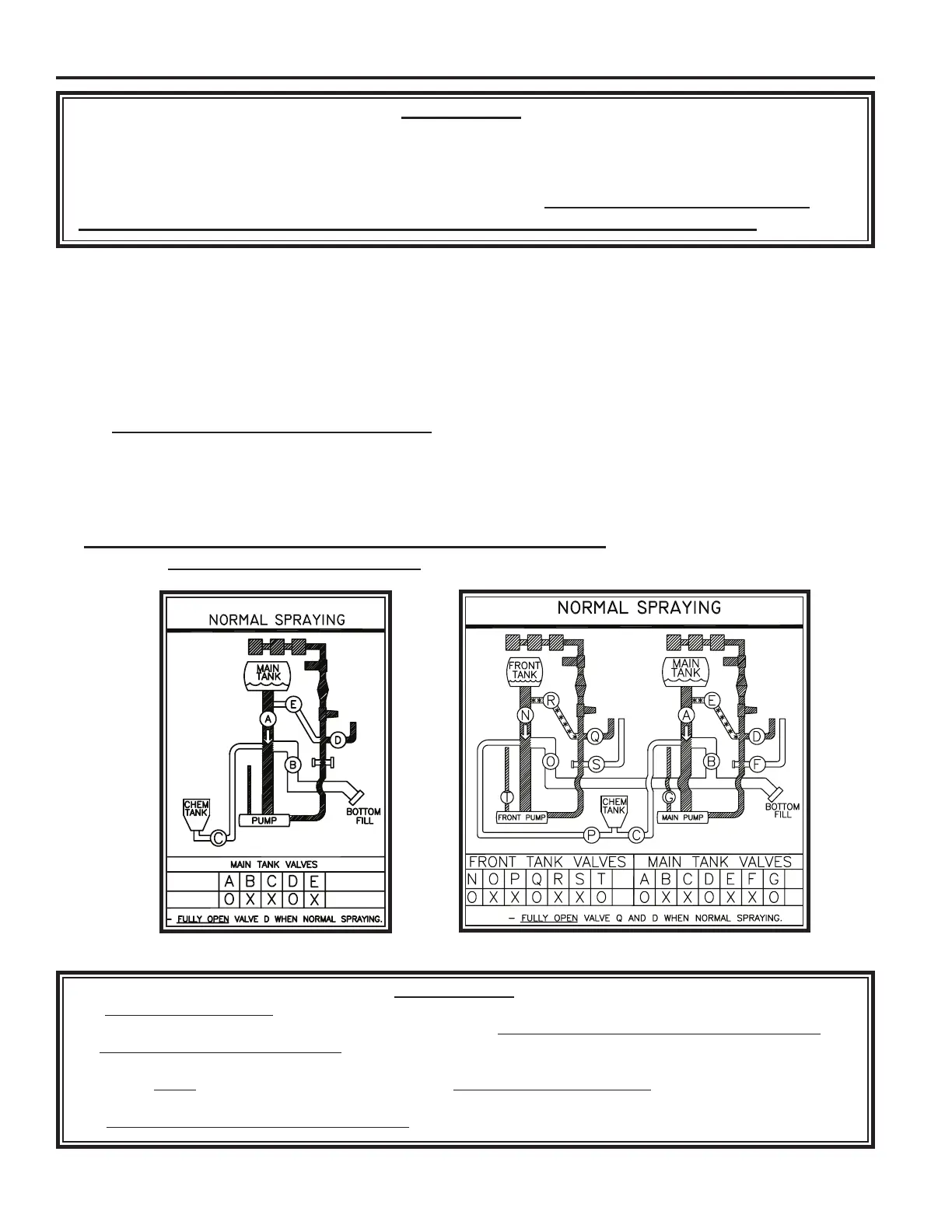

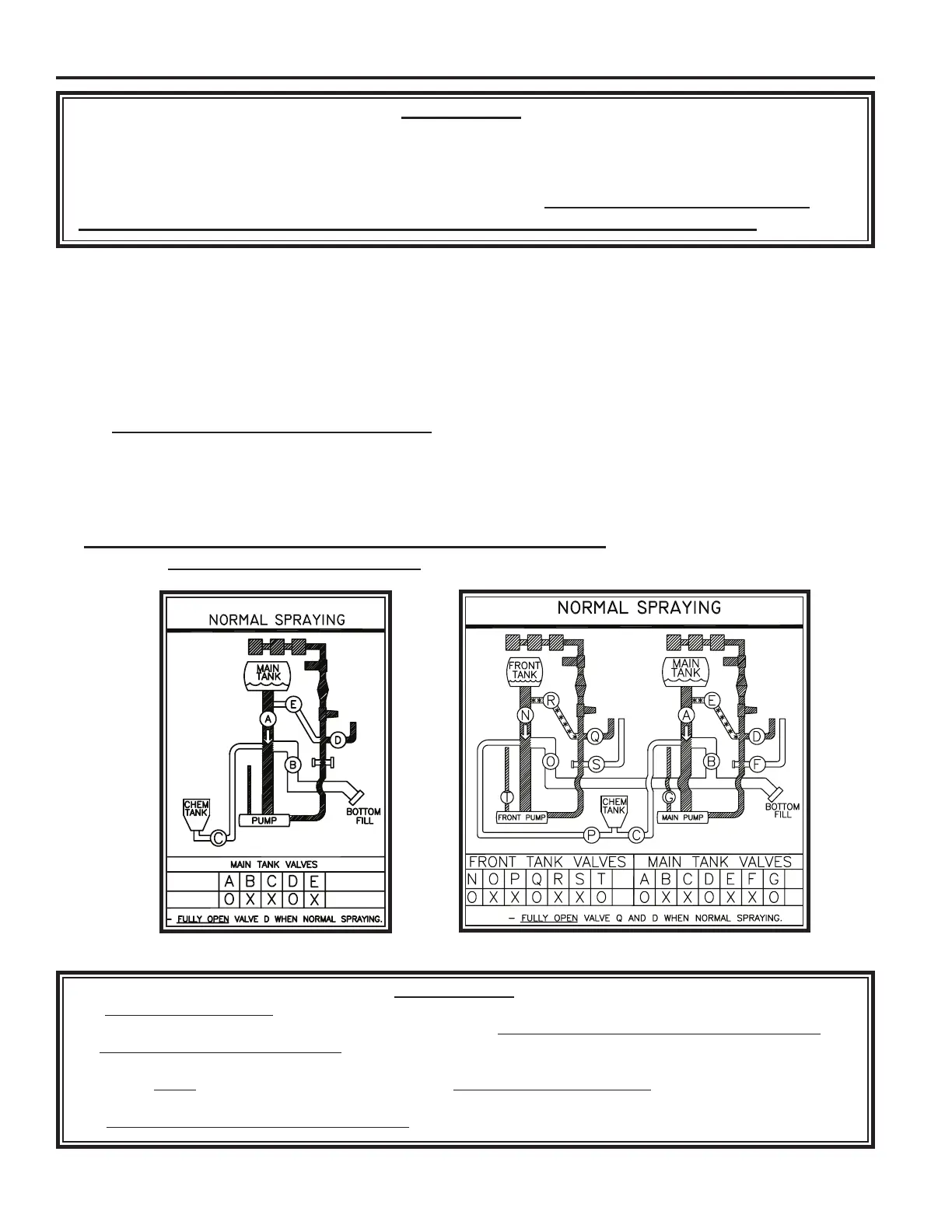

1. SET UP NORMAL SPRAYING

IMPORTANT!

1. NEVER RUN PUMP DRY. THE MECHANICAL SEAL BETWEEN THE PUMP AND POWER

SOURCE DEPENDS UPON LIQUID FOR LUBRICATION. SEAL DAMAGE FROM RUNNING PUMP DRY

IS NOT COVERED BY WARRANTY.

2. SINCE BOTH THE HYDRAULIC AND PTO PUMPS ARE CENTRIFUGAL PUMPS, BOTH THE BOOMS,

AS WELL AS THE MANUAL VALVES D AND Q CAN BE SHUT OFF WITHOUT DAMAGING THE PUMP

PROVIDED THE PUMP IS NEVER RUN DRY.

IMPORTANT!

OUTER BOOM SWITCH MUST BE DEACTIVATED FOR BOOM TO BREAK AWAY WHEN

CONTACTING AN OBSTRUCTION. FAILURE TO DEACTIVATE SWITCH WILL CAUSE

PHYSICAL DAMAGE AND POSSIBLY BODILY INJURY. BOOM DAMAGE CAUSED BY

FAILURE TO MAKE BREAK AWAY OPERATIVE WILL NOT BE WARRANTED.

I. Activate part 3 boom fold switch (if equipped with 3 section boom) and select tractor hydraulics to

unfold part 3 booms.

J. Deactivate part 3 boom switch.

K. Activate vertical height switch and select tractor hydraulics to adjust height of spray boom.

L. Deactivate vertical height switch.

2. LEARN THE CORNER TURNING LIMIT

Know how sharp a corner can be made without interference between tractor and sprayer when sprayer

is folded and unfolded. Every tractor connection is different so know the limits.

Loading...

Loading...