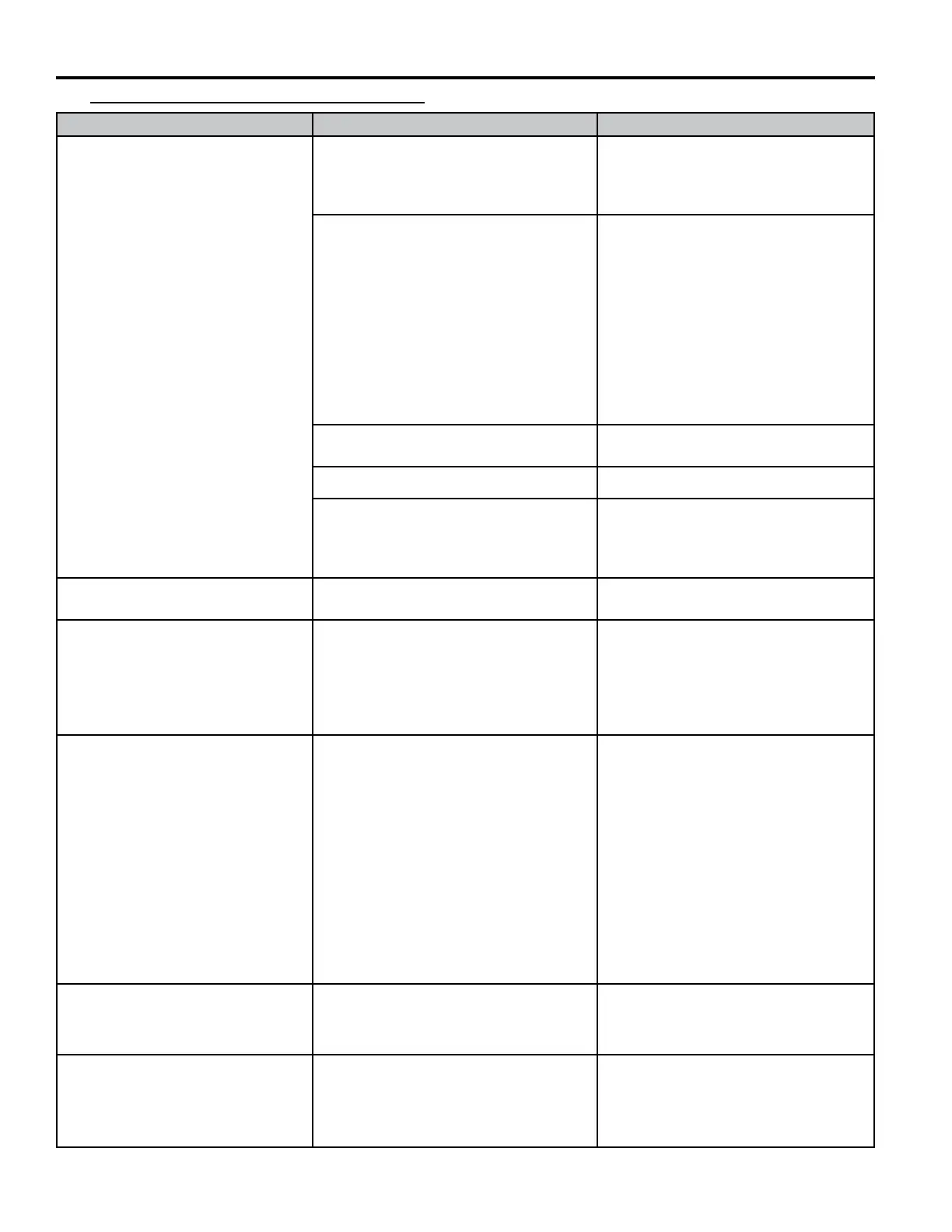

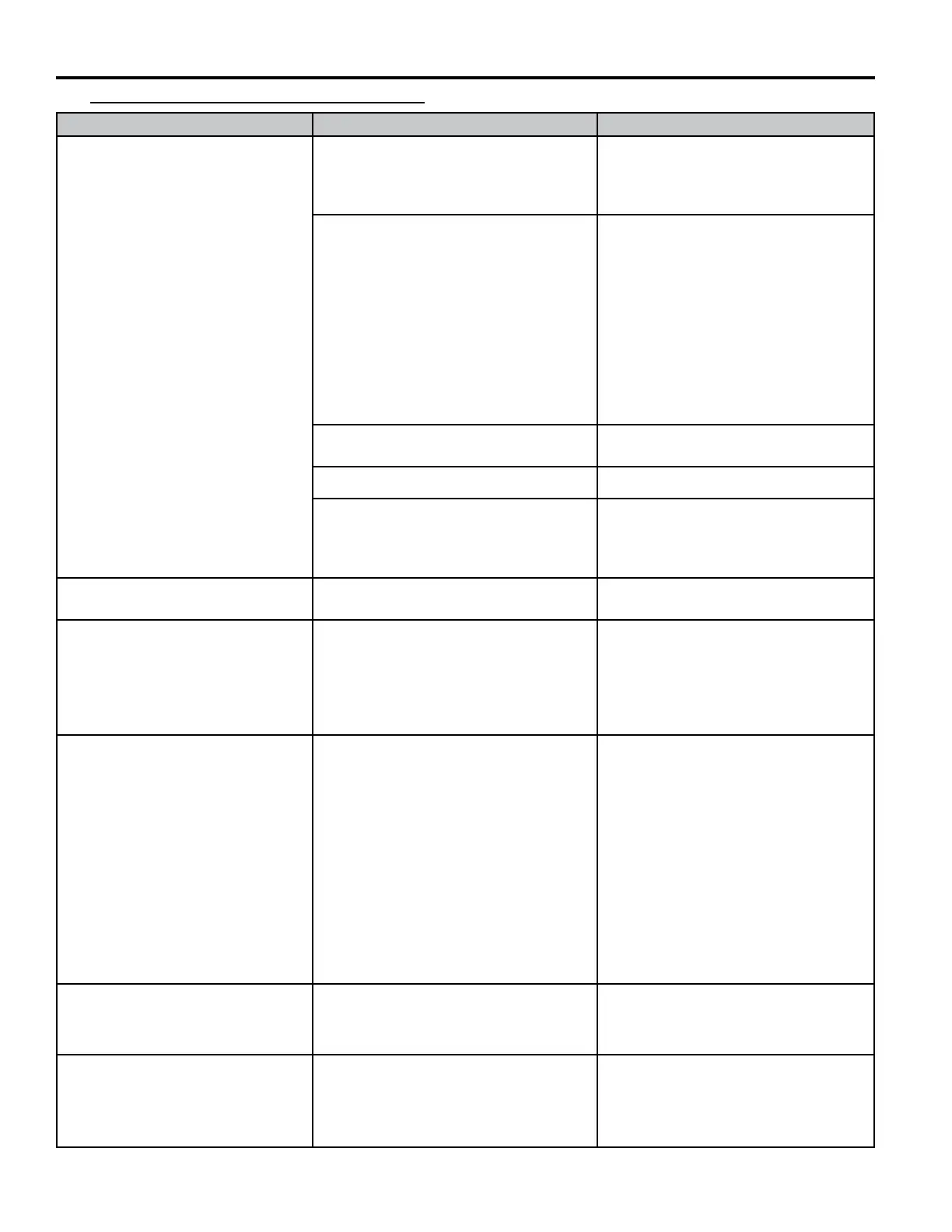

SECTION 4 - TROUBLESHOOTING

4.2

PROBLEM PROBABLE CAUSE CORRECTION

6. Not getting application rate for a

given pressure setting.

A. Controller in Rate 1 or Rate 2 position.

Move Rate Control Switch to Manual

position & hold Increase switch up with

Master Switch & at least one boom

switch in ON position.

B. Restriction in plumbing.

a) Clean/Replace Main Line Strainer

(strainer may look clean, but holding up

to a light can reveal possible restriction).

b) Check for restriction on suction side

of pump. (Rinse Ball from sprayer tank

could be in sump.) (Mouse nest, rag(s)

or other contamination from tank might

have gotten into the plumbing.)

c) Clean/Replace Boom Line Strainers

d) Clean/Replace Nozzle Body Strainers

and/or spray tips.

C. Crossover Plumbing Valve in OPEN

position.

Turn Crossover Plumbing Valve to

CLOSED position.

D. Tank Rinse Valve left on. Turn Tank Rinse Valve to off.

E. Cracked or split pump impeller (dam-

aged impeller is capable of developing

some pressure, but not able to product

volume).

Replace damaged impeller.

7. Unable to maintain spray rate at

usual speed

Restriction in plumbing.

(SEE ABOVE) á

8. Steady Alarm/Rate 0.0 Pressure too

low

No speed signal to Controller

a) Select SPEED to verify zero

speed reading.

b) Conrm correct SPEED CAL #

c) Check speed sensor for func-

tionality.

9. Stady Alarm/Rate 0.0 Pressure too

high

No Flow signal to Controller

a) select VOL/MIN key to verify

zero volume reading.

b) Conrm correct METER CAL

#.

c) Check wiring for possible

breaks/kinks (common on draw-

bar/cab articulation points).

d) Verify meter impeller can spin

freely.

e) Replace owmeter transducer

or entire owmeter.

10. Intermittent Alarm “Low Level”

ashes

Low Limit alarm activated

Increase speed when possible - or

reset/disable Low Limit setting.

See Raven Manual.

11. Intermittent Alarm “Low Level”

ashes

Low Tank Level alarm activated

Enter correct TANK VOL when

lling sprayer tank - or disable

Low Level alarm. See Raven

Manual.

4.1. SPRAYER SYSTEM TROUBLESHOOTING

Loading...

Loading...