WARNING: When the power of PV module is greater than the rated

chargingpower, and the maximum open-circuitvoltageof PV array is more

than 96V (at the lowest environmental temperature), the controller may be

damaged.

According to “Peak Sun Hours diagram”, if the power of PV array exceeds the rated

charging power of controller, then the charging time as per the rated power will be

prolonged, so that more energy can be obtained for charging the battery. However, in

the practical application, the maximum power of PV array shall be not greater than 1.5

x the rated charging power of controller. If the maximum power of PV array exceeds

the rated charging power of controller too much, it will not only cause the waste of PV

modules, but also increase the open-circuit voltage of PV array due to the influence of

environmental temperature, which may make the probability of damage to the

controller rise. Therefore, it is very important to configure the system reasonably. For

the recommended maximum power of PV array for this controller, please refer to the

table below:

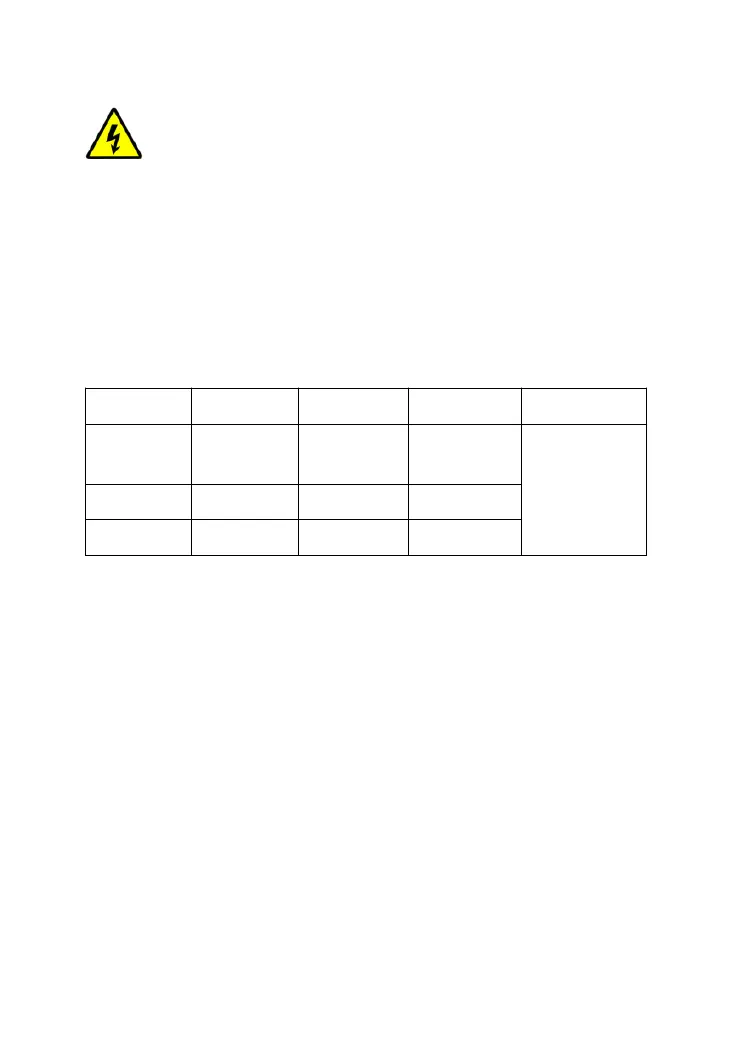

Model

-M4024 40A

520W/12V

1040W/24V

780W/12V

1560W/24V

①At 25℃ environmenttemperature

②At minimum operating environmenttemperature

2.3 WireSize

The wiring and installation methods must conform to all national and local electrical

code requirements.

PV Wire Size

Since PV array output can vary due to the PV module size, connection method or

sunlight angle, the minimum wire size can be calculated by the Isc

*

of PV array.

Please refer to the value of Isc in the PV module specification. When PV modules

connect in series, the Isc is equal to a PV modules Isc. When PV modules connect in

parallel, the Isc is equal to the sum of the PV module’s Isc. The Isc of the PV array

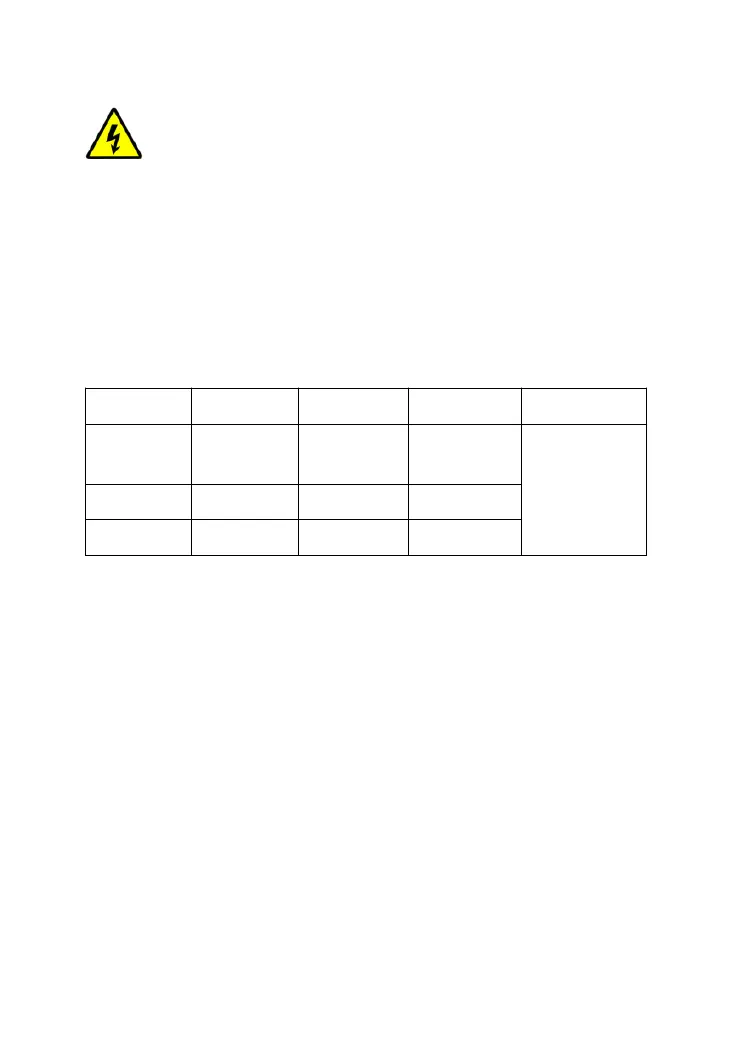

must not exceed the controller’s maximum PV input current. Please refer to the table

as below:

NOTE: All PV modules in a given array are assumed to be identical.

*Isc=short circuit current(amps) Voc=open circuit voltage.

9

Loading...

Loading...