14

3

ADJUSTMENT OF THE SEWING MACHINE

Caution

▶When installing a needle, be sure to turn the power switch off. If the user mistakenly steps

on the foothold, the machine will automatically start and can cause injuries.

▶T

he clutch motor will continue to run for a while due to inertia even after you turn the power

switch off. Be sure to work with the sewing machine after the motor comes to a complete stop.

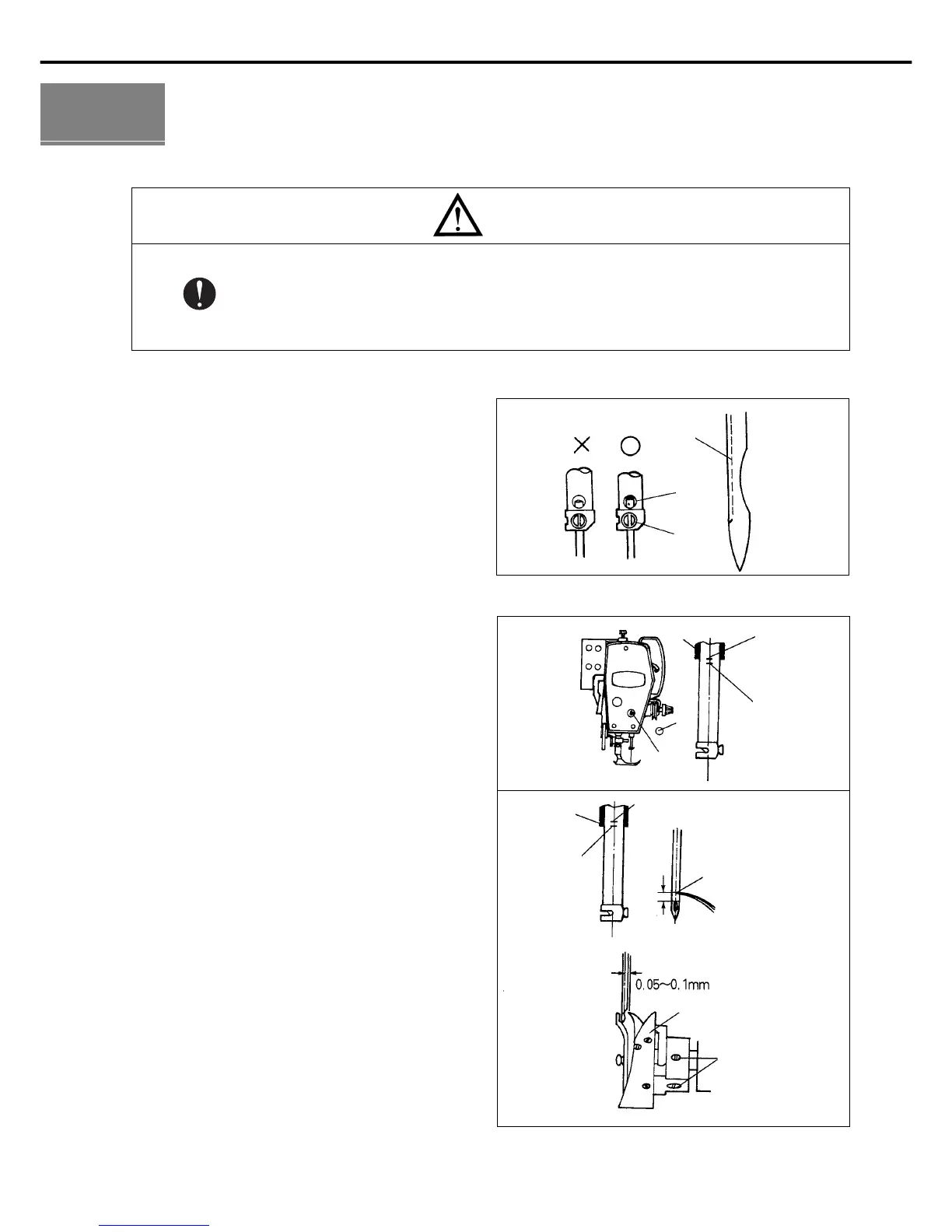

1) Inserting a needle

With the groove ① of the needle facing inwards, press

the needle tip against the upper side of the stopper hole

②. Fix the needle with a tightening screw ③. (Refer to

Figure 13)

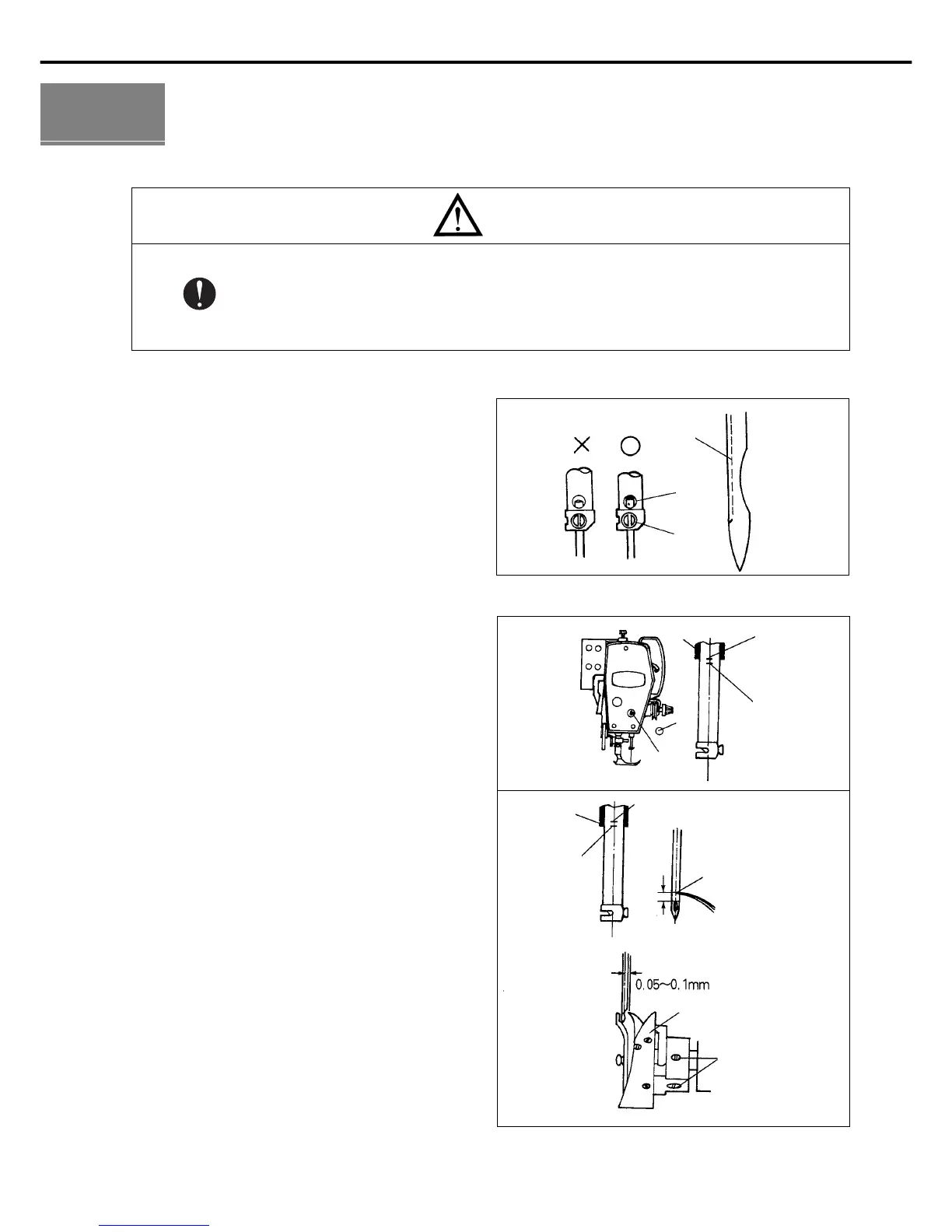

As shown in Figure 14, take out the rubber cap ④ of the

needle bar-adjusting hole in the faceplate. Turn the

pulley to bring the needle bar to its lowest point and

loosen the screw ⑤ of the needle bar holder. Adjust the

needle bar to bring the lower side of the needle bar rear

bushing ⑥ to align at a carved mark ⑦ where the lowest

point of the needle bar comes to. Then, fix firmly with

the screw ⑤ and cover with the rubber cap ④.

2) Adjusting a needle bar

As shown in Figure 14, align the lower side of the needle

bar bushing ⑥ with a carved mark ① in the needle bar.

Loosen three screws ② of the hook.

Turn the loose hook to align the upper tip ③ of the hook

with the needle center. Set the distance from the inside

of the groove to the upper tip of the hook ③ at

0.05~0.1mm. Re-tighten with the three screws ②.

3)

Timing adjustment of the needle and hook

[ Figure 13 ]

[ Figure 14 ]

①

⑥

⑦

④

⑤

⑦

③

②

①

⑥

Hook

about 0.5mm

①

②

③

Loading...

Loading...