8

1

SPECIFICATIONS

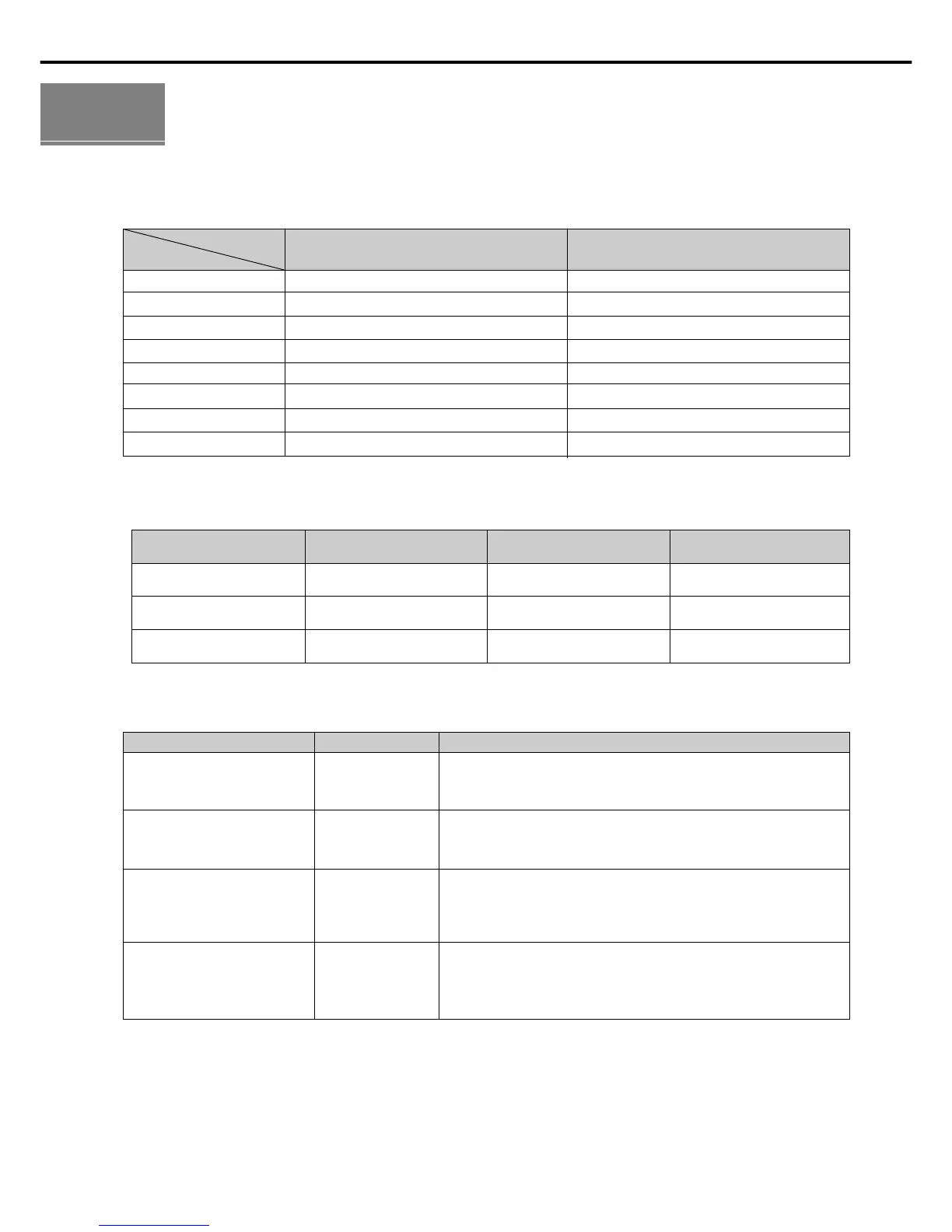

1) Sewing machine

2) Controller of Servo Motor

MODEL

SC55-1A

SC55-2A

SC55-3A

VOLT

1-phase 110V

1-phase 220V

3-phase 220V

WATT

550W

550W

550W

HERTZ

50/60 Hz

50/60 Hz

50/60 Hz

Description

Type

KM-235A KM-235B

Application

Maximum speed

Maximum number of stitch

Needle used

Thread used

Height of feed dog

Feed dog

Height of presser foot

For light and medium heavy materials

5,500 SPM

5mm

DB x 1#14 (#9~#18)

Cotton #30~#120

0.8mm~1mm

3 match for general, 4 match for heavy

Manual: 5.5mm, Knee: 13mm

For heavy materials

4,500 SPM

7mm

DB x 1#21 (#20~#25)

Nylon 150~250 DENIER

1.2mm

3 match

Manual: 5.5mm, Knee: 13mm

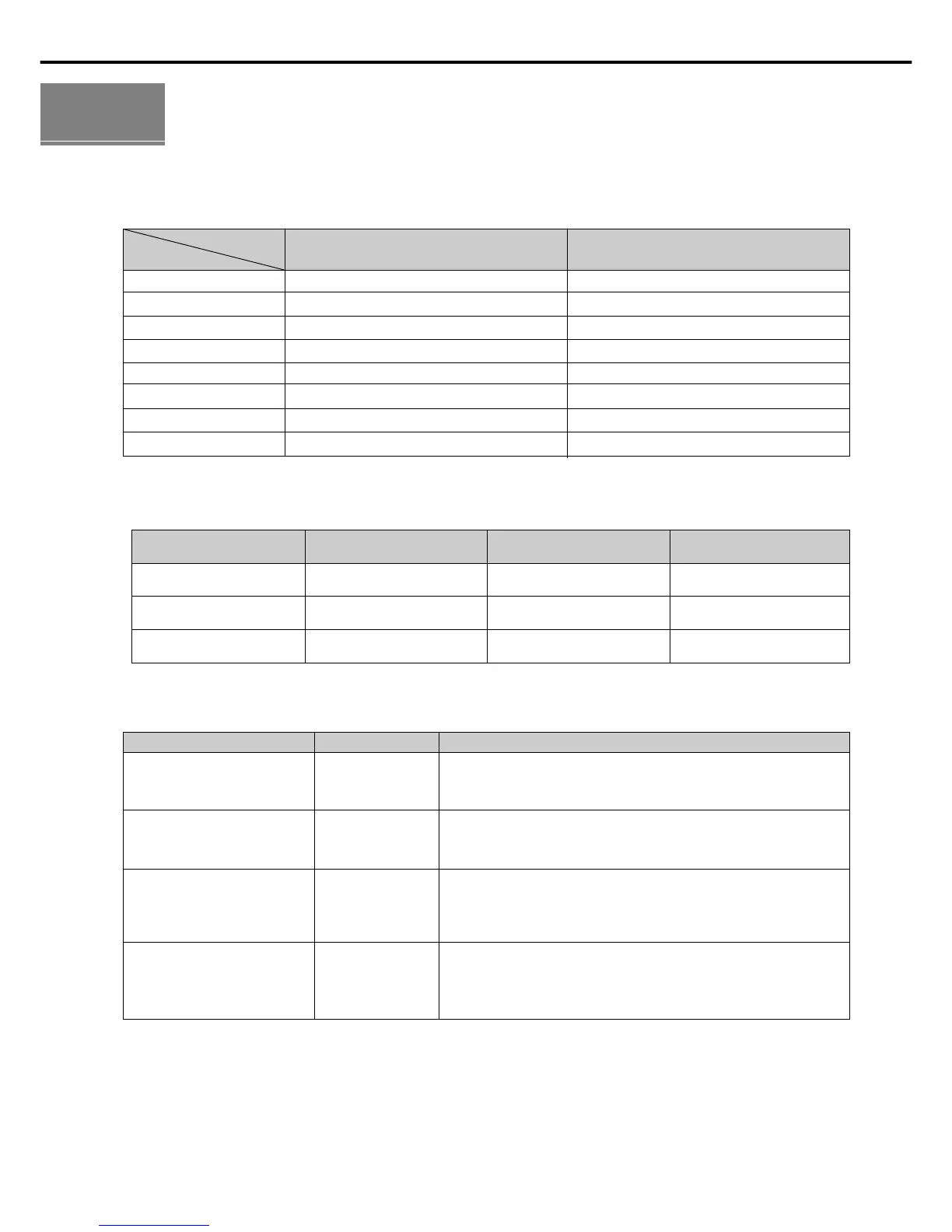

ApplicationModelName of option

Auto knee lifting system

Production counter

Material edge sensor

SCOUN-1

SEDG-1A

SEDG-2A

A counting device which indicates the completed quantity on the

program unit panel, including added, subtracted, corrected or

remaining quantity along with other performance rates

A device that senses the edge or thickness of the sewing

material to stop the machine without manual pedaling. Available

in two types: SEDG-1 for edge sensing type and SEDG-2 for

thickness sensing type

Standing pedal

SPDL-1

SPDL-2

A device needed when only one operator runs several sewing machines.

Pedals for acceleration, thread trimming, presser foot and ascending are

built separately. Two types, SPDL-1 and EDPL-1 for fixed speed type and

SPDL-2 and EDPL-2 for adjustable speed type are available.

SPF-2A

Solenoid structure. The presser foot lifts automatically by 1-step

backward pedal movement

3) Peripheral automation devices (optional)

Loading...

Loading...