15

Caution

▶When checking lubrication of the thread take-up unit and the hook, keep your hands or oil

check paper away from peripheral feeding devices in order to prevent injuries.

5) Adjusting the oil supply of the hook

As shown in Figure 16, the level of oil will increase as

you turn the screw ① inserted in the lower shaft front

bushing, in a clockwise direction (+). Turn it

counterclockwise (- ) to reduce the oil supply.

[ Figure 16 ]

Less

More

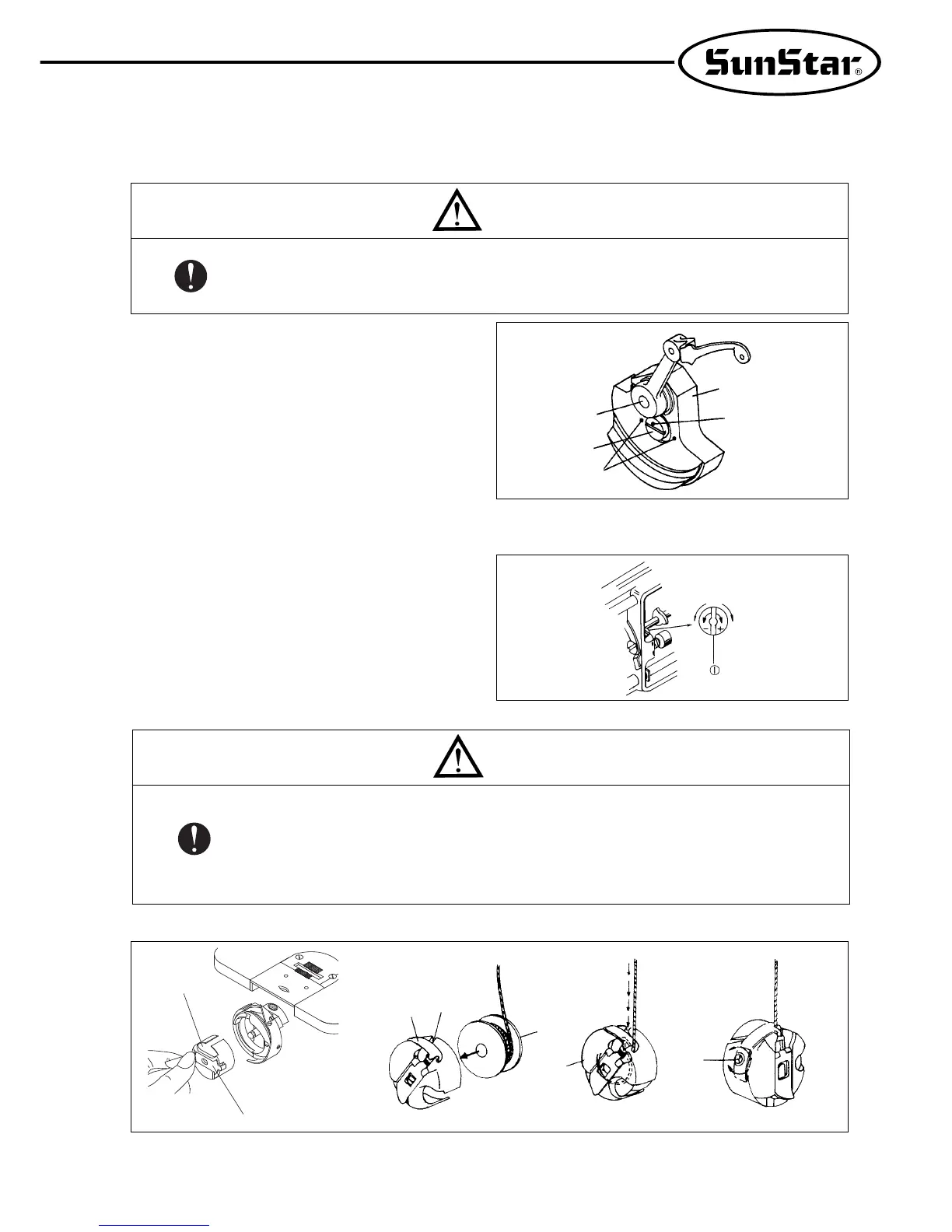

4) Adjusting the oil supply of thread

take-up unit

As shown in Figure 15, the level of oil supply will increase

when a dot ② in the lubrication-adjusting pin ① aligns with

the center hole of the thread take-up lever crank shaft ③.

When you adjust the dot closer to a carved dot ⑤ in the link

cam ④, the level of oil supply will decrease. Also, no oil

will come out when you adjust the carved dot ② to move

pass the carved dot ⑤. (The left/right adjustment range of

the lubrication-adjusting pin ① is 90°.)

[ Figure 15 ]

①

②

④

⑤

③

[ Figure 17 ]

⑤

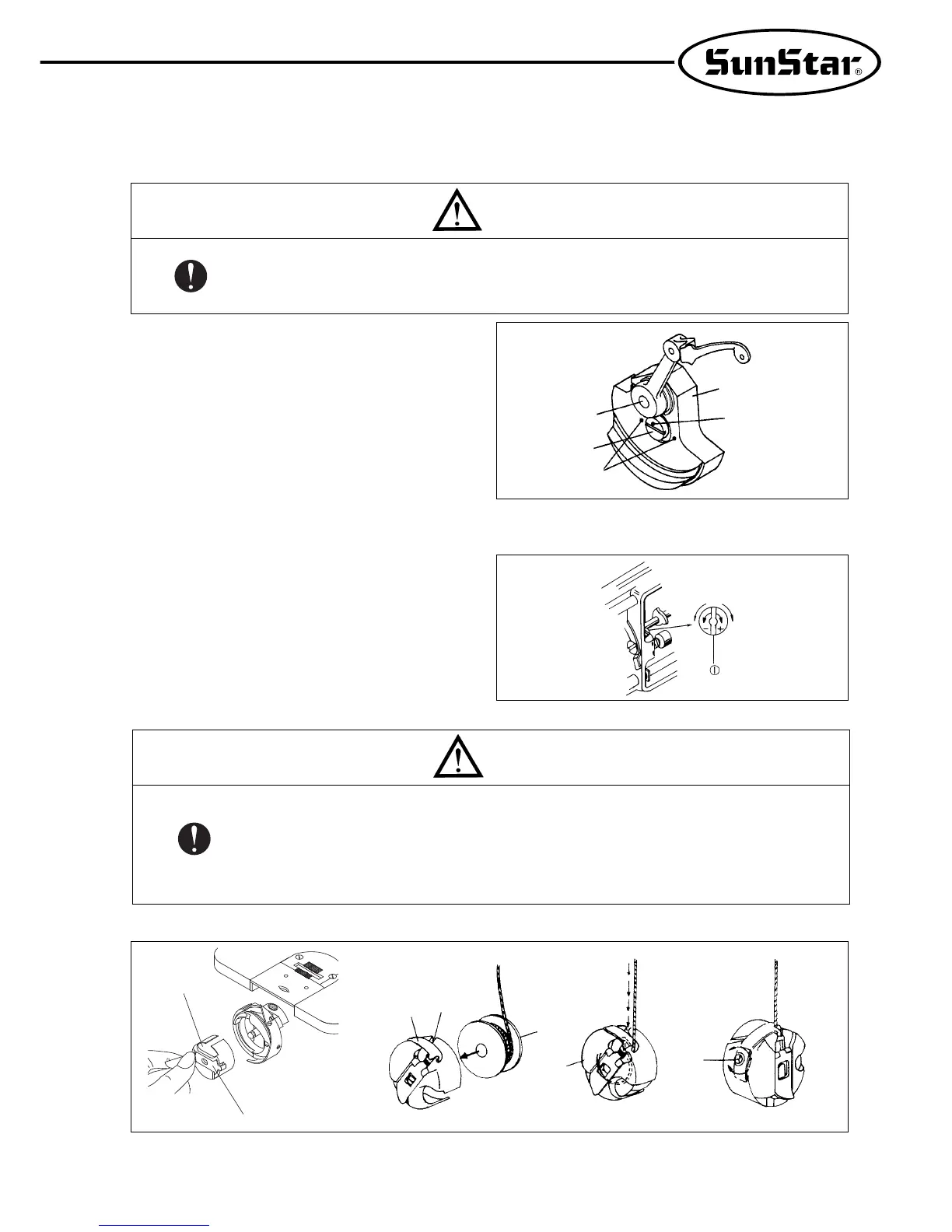

6) Placing lower thread and adjusting tension

④

③

②

①

①

⑥

Caution

▶When adjusting lower thread tension, be sure to turn the power switch off.

If the user mistakenly steps on the foothold, the machine will start automatically and can

cause injuries.

▶

The clutch motor will continue to run for a while due to inertia even after you turn the power

switch off. Be sure to work with the sewing machine after the motor comes to a complete stop.

Strong

Weak

Loading...

Loading...