19

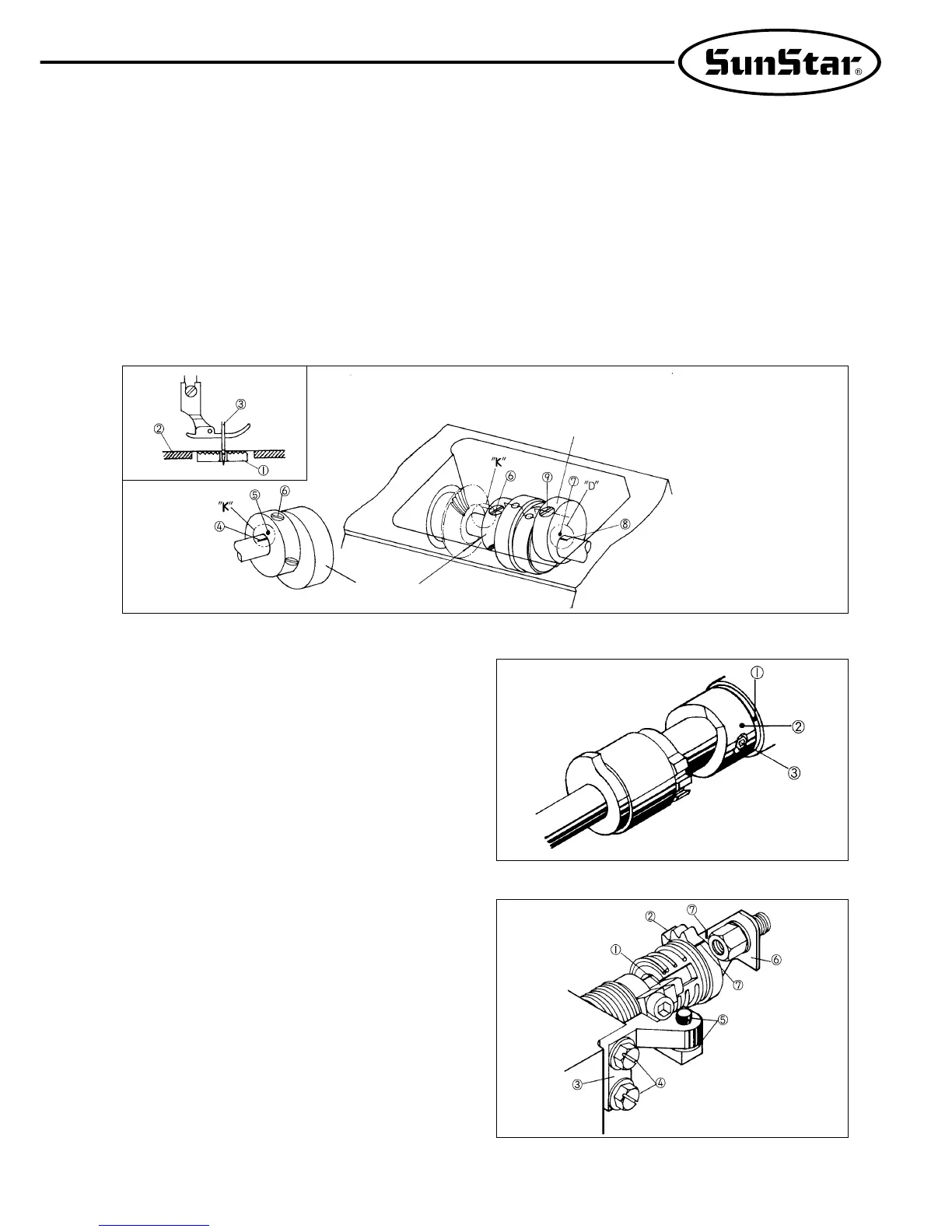

12) Adjusting the feed cam

As shown in Figure 25, turn the pulley by hand to lower the end of the feed dog ①. When it aligns with the upper side of the

needle plate ②, adjust the upper end of the needle hole of the needle ③ to align with the upper side of the needle plate ②. Also at

this point, the upper shaft carved line ④ and the carved dot ⑤ of the feed cam “A”will come in alignment with “K”as shown in

Figure 25. Afterwards, adjust the feed cam “A”and “C”by bringing the carved dot ⑦ of the feed cam “C”and the upper shaft

carved line ⑧ in alignment with “D”. At this point (when the standard feed cam adjustment is complete), the center of no. 2 screw

⑥ of the feed cam “A”and the center of no. 1 screw ⑨ of the feed cam “C”will have come in alignment. Depending on the type

of sewing materials, however, the center of no. 2 screw ⑥ and that of no. 1 screw could be slightly off from a straight line.

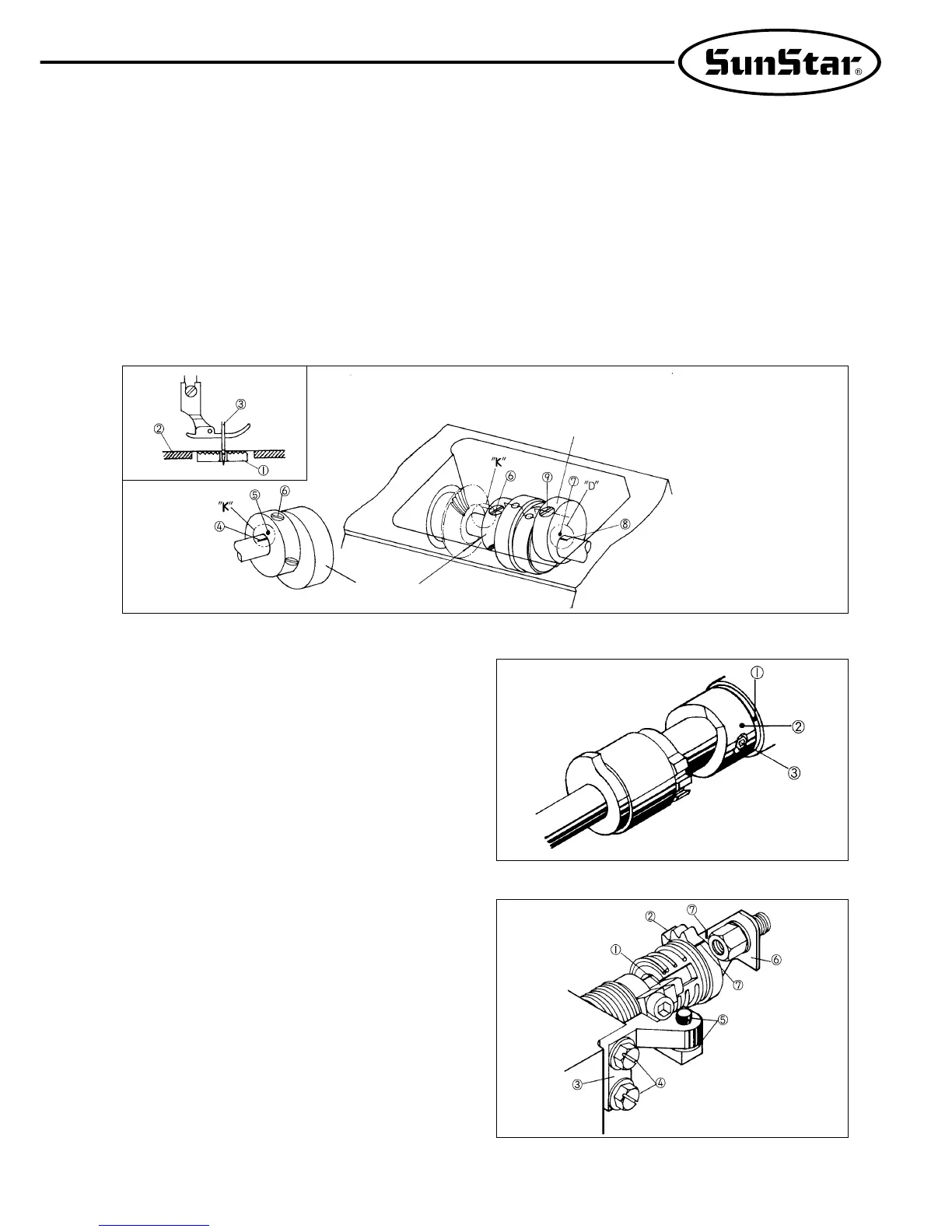

[ Figure 26 ]

[ Figure 27 ]

13)

Timing adjustment of trimming devices

A. Turn the pulley by hand to bring the needle bar

accurately to its lowest point. Bring the carved dot ①

of the lower shaft middle bushing in the bed, with the

location dot ② of the trimming cam. Tighten with

two fixing screws ③. (Refer to Figure 26)

B. Fixing the “B”position of trimming drive gear

a)

As shown in Figure 27, check how the trimming drive

gear “B”② is inserted into the stopper lever ①.

b) With the stopper lever ① pressed against the

stopper rubber ⑤ of the stopper ③, loosen two

fixing screws ④.

c) Move the trimming drive gear “B”② , and adjust

the stopper ③ up and down in order to align the

thread release drive lever ⑥ with the carved line

⑦ of the trimming drive gear “B”. Tighten two

fixing screws ④ firmly while the baselines are

aligned with each other.

[ Figure 25 ]

Feed cam “A”

Feed cam “C”

Loading...

Loading...