10

33

BASIC OPERATIONAL METHOD

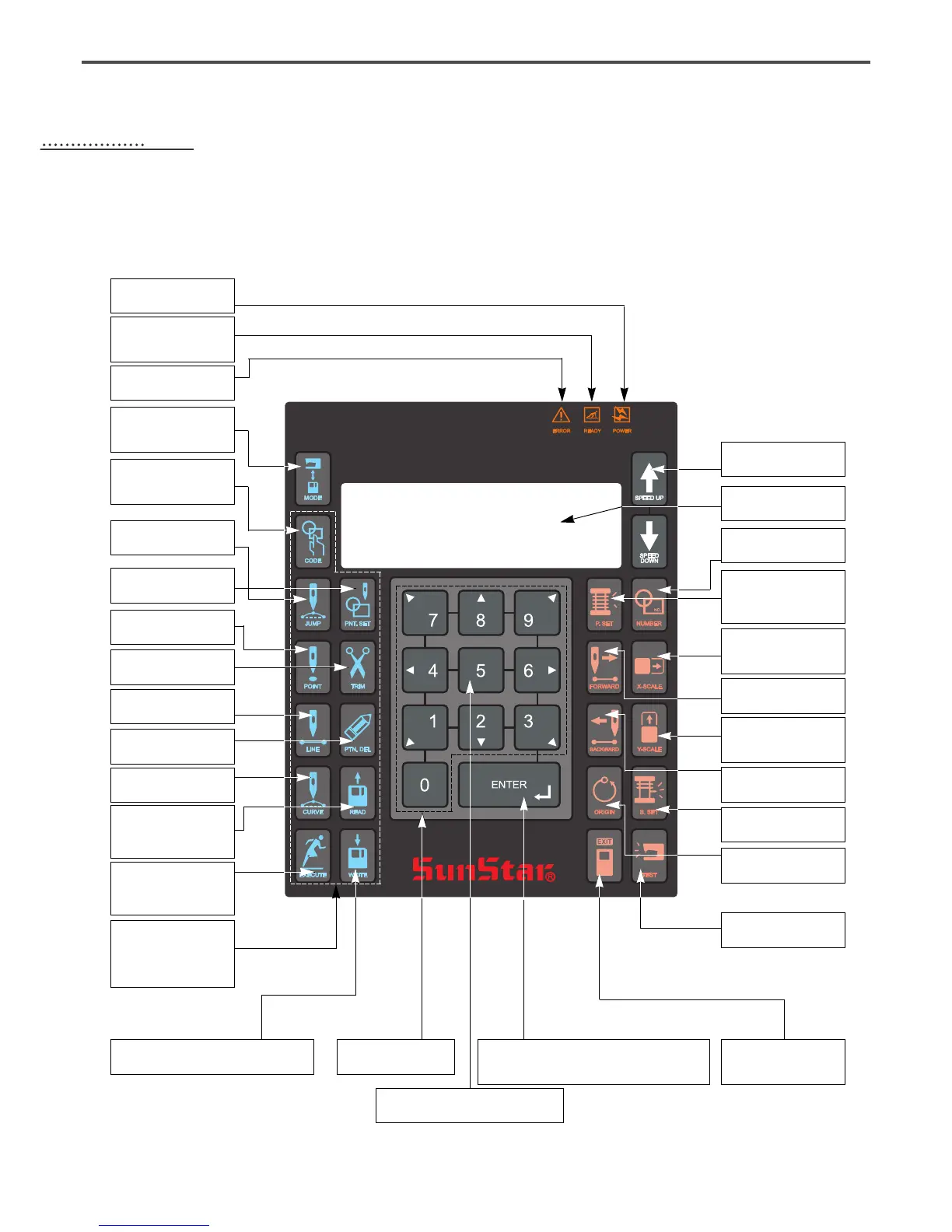

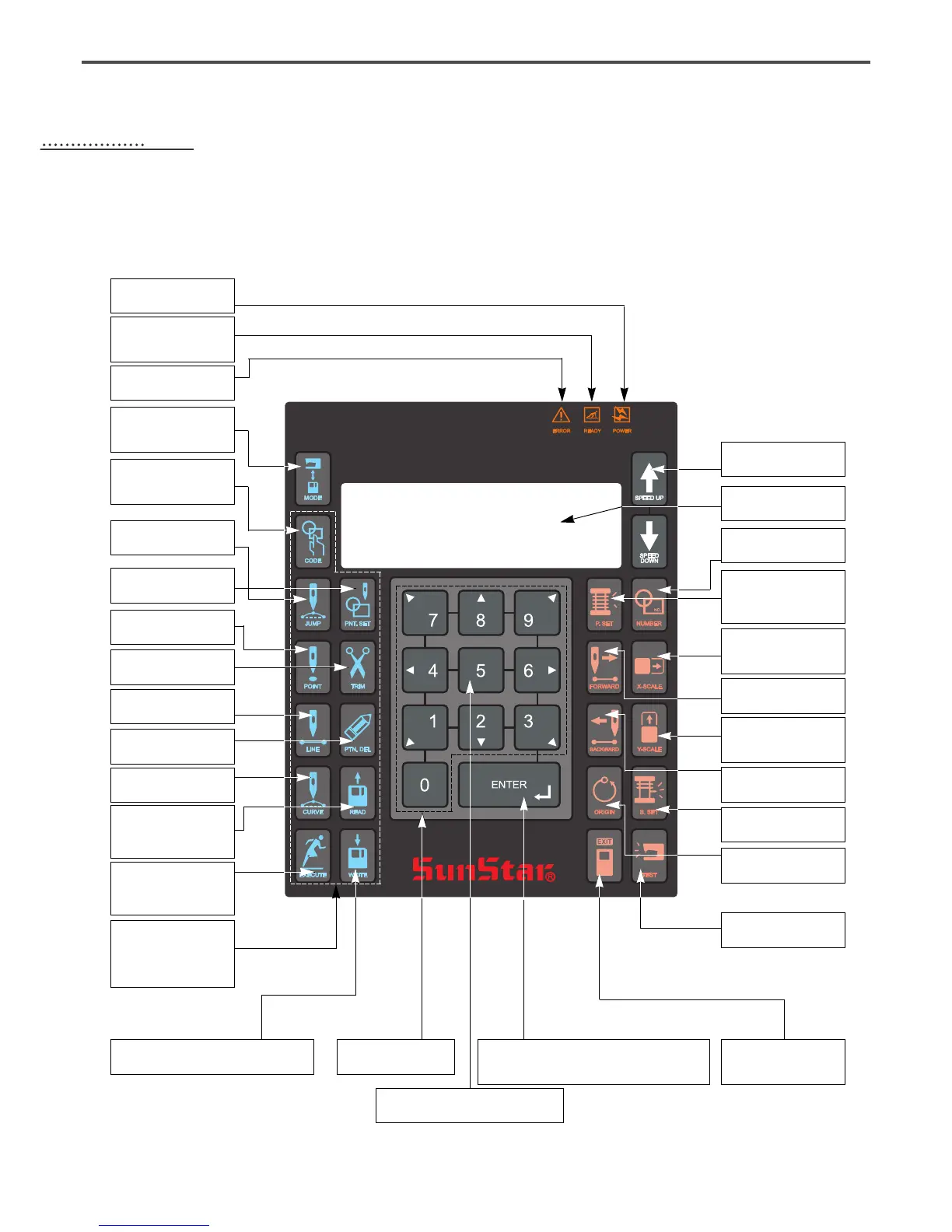

1) Name and Roles of Each Key on Operation Unit

POWER LED

Input of power

READY LED

Sewing available

condition

ERROR LED

Errors occurred

MODE KEY

Change of working

mode

CODE KEY

Selection of function

code

POINT KEY

Input of point code

JUMP KEY

Input of jump code

POINT-SET KEY

Input of point

TRIM KEY

Input of trim code

LINE KEY

Input of straight code

PATTERN-DELETE KEY

Delection of pattern code

CURVE KEY

Input of curve key

PUNCHING RELATED KEY

It can be used for pattern data generation

ENTER KEY

Pressed to cancle sewing function setups

or to end input

DIRECTION/DIGIT KEY

Threading and Unthreading Key

ESCAPE KEY

Cancle of function to

be selected

EXECUTION KEY

Designation of start

for code generation

WRITE KEY

Used to write the

pattern onto the

USB Flash Drive

READ KEY

Reading patterns from

a USB Flash Drive

NO. KEY

Input of pattern NO.

X_SCALE KEY

Use when it is extended or

reduced to the X direction

Y_SCALE KEY

Use when it is extended or

reduced to the Y direction

P. SET KEY

Counter setting for

working capacity

FORW KEY

1 Stitch forward

BACK KEY

1 Stitch backward

B. SET KEY

Counter setting of bottom thread

SPEED KEY

Change of sewing speed

LCD DISPLAY

Indication of contents

TEST KEY

Change to test sewing mode

ORIGIN KEY

Returning to origin

Loading...

Loading...