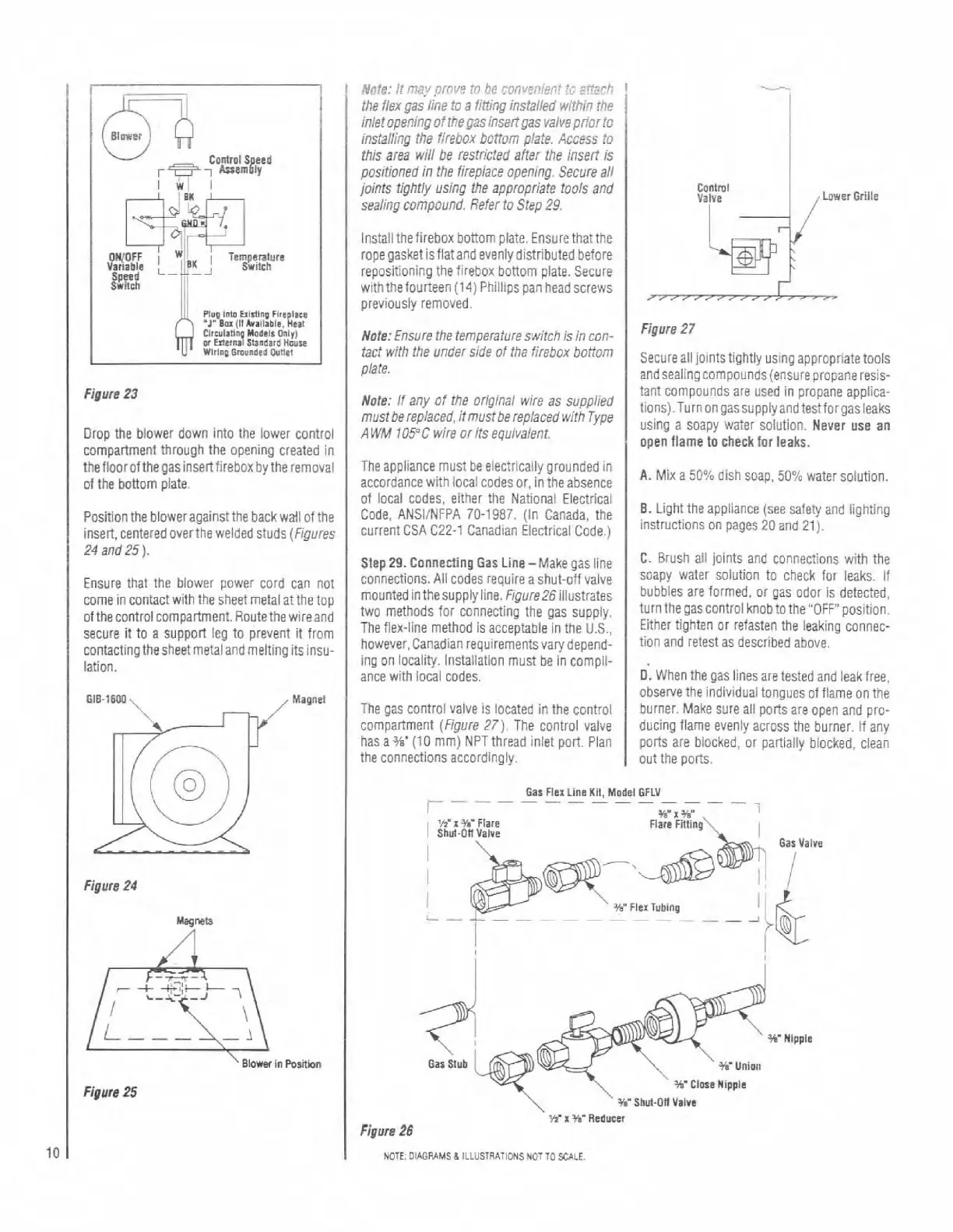

Figure

23

Drop the blower down into the lower control

compartment through the opening created

In

thefloorofthegasinsertfirebox

by

the removal

of the

bonom plate.

Position the bloweragainst the back

wall of the

insert, centered

overthe welded studs (Figures

24

and25).

Ensure that the blower power cord can not

come in contactwith the sheet metal at the top

ofthecontrol compartment. Route the

wireand

secure

it

to a support leg to prevent it from

contactingthesheet

metaland rneiting itsinsu-

lation.

Figure

24

Figure

25

h(l.I.3:

i!

rn??

poi,?

t;,

he

rov>fni.e.;t

ti?

gr?rh

the flex yas line to a fining installed w~thin the

h!etope.?iny ofthe 03s insertgas valvepriortc

instaiiing the firebox bonorn plate. Access to

this area wili be restricted after the

insert is

positioned

in

the fireplace opening. Secure ail

joints

tighty using the appropriate tools and

sealing compound Refer to Step

29.

Installthefirebox bottom plate. Ensure thatthe

ropegasket isfiatand evenly distributed before

repositioning the firebox

bonom plate. Secure

with

thefourteen

(14)

Phiilips pan headscrews

previously removed.

Note: Ensure the

temperatureswitch isin con-

tact wlth the under side of the firebox

bottom

piate.

Figure

27

Secure all jOintStiQhtly using appropriate tools

and sealing compounds (ensure propane resis-

T-eapp lace rust

te

e ec:r ta tt~r,!~ncro

,*

acccr~a-ce

hi:n

cca c3t:es

tr,

in rlsansence

I

A.

h'tx a

EC9.>

ckn soap

50';

wi.:e. :ol.r

:I?.

Note:

if

any of the orioinal wire as suppiied

musrbere~laced,itrnustbere~iacedwifh

Type

A

WM

IOS'C

wire or its equivalent.

tant compounds are used in propane

applica-

tions).~urnongassupplyand

testforgasleaks

using

a

soapy

water

solution,

Never

use

an

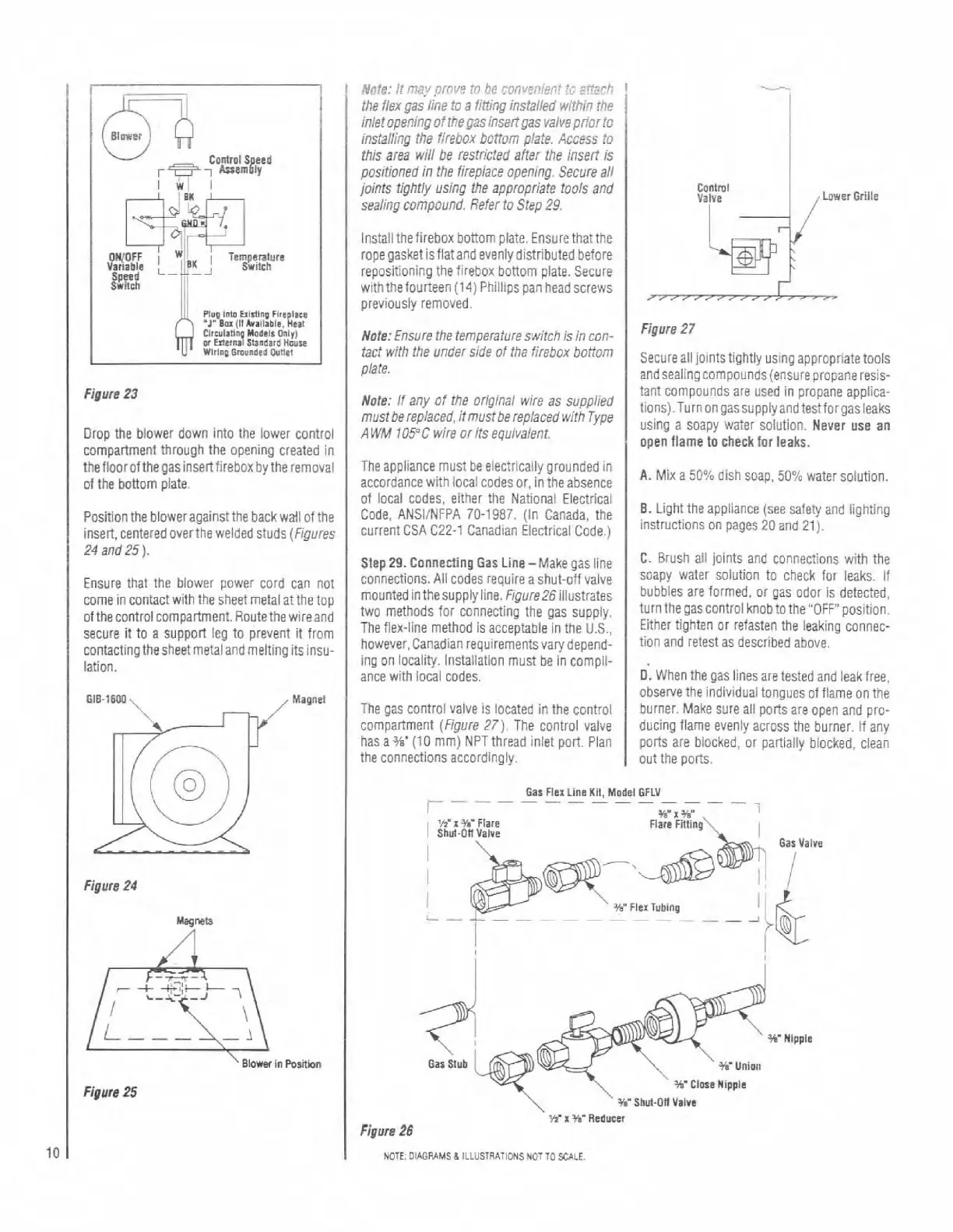

step

29.

connecting

G~~

~i~~-~~k~

gas

line

C.

Brush 211 joints and connections with the

connections. Ail codes reauire a

sh~~t-nff valve

I

Soapy water solution to check for leaks. If

I

open flame to

check

for leaks.

of local codes, either the National Eiectricai

Code.

ANSIINFPA

70-1987.

(In Canada, the

current

CSA

CZZ-1 Canadian Electrical Code.)

~~

~

~

~~~~~

~7-

-

~

~-

~.

mountedinthesupply line. Figure26lilusfrates

bubbles are formed. or gas odor is detected,

two methods for connecting the gas supply.

tUr"heQasc0ntrol knobtothe"0FF"position.

The flex-line method is acceotabie in the

11s.

Either tighten or refasten the leakinq connec-

0.

Light the appliance (see safety and lighting

i"s"uc'ions on pages

20

and

21).

however, Canad~an re~ulremknts vary depend:

I

tlon and retest as

described

above

ing on locality.

Installation must be

h

cdrnpli-

ance with local codes.

The gas control valve is located in the control

compartment (Figure

27)

The control valve

has a

J/8'

(10

mm) NPT thread inlet port. Plan

the connections accordingly.

D.

When the gas lines are tested and leak free,

observe the Individual tongues of flame on the

burner. Make sure all

pons are open and pro-

ducing

fiarne evenly across the burner. If any

ports are blocked, or partially blocked, clean

out the ports.

Gas

Flex

Line

KII,

Model

GPLV

-

-

-

-

- -

-

-

- - -

-

3b'

Nipple

Gar

Slub

NOTE.

OIAGPAMS

d

ILLUSlRAllONSNOTTOSCALE

Loading...

Loading...