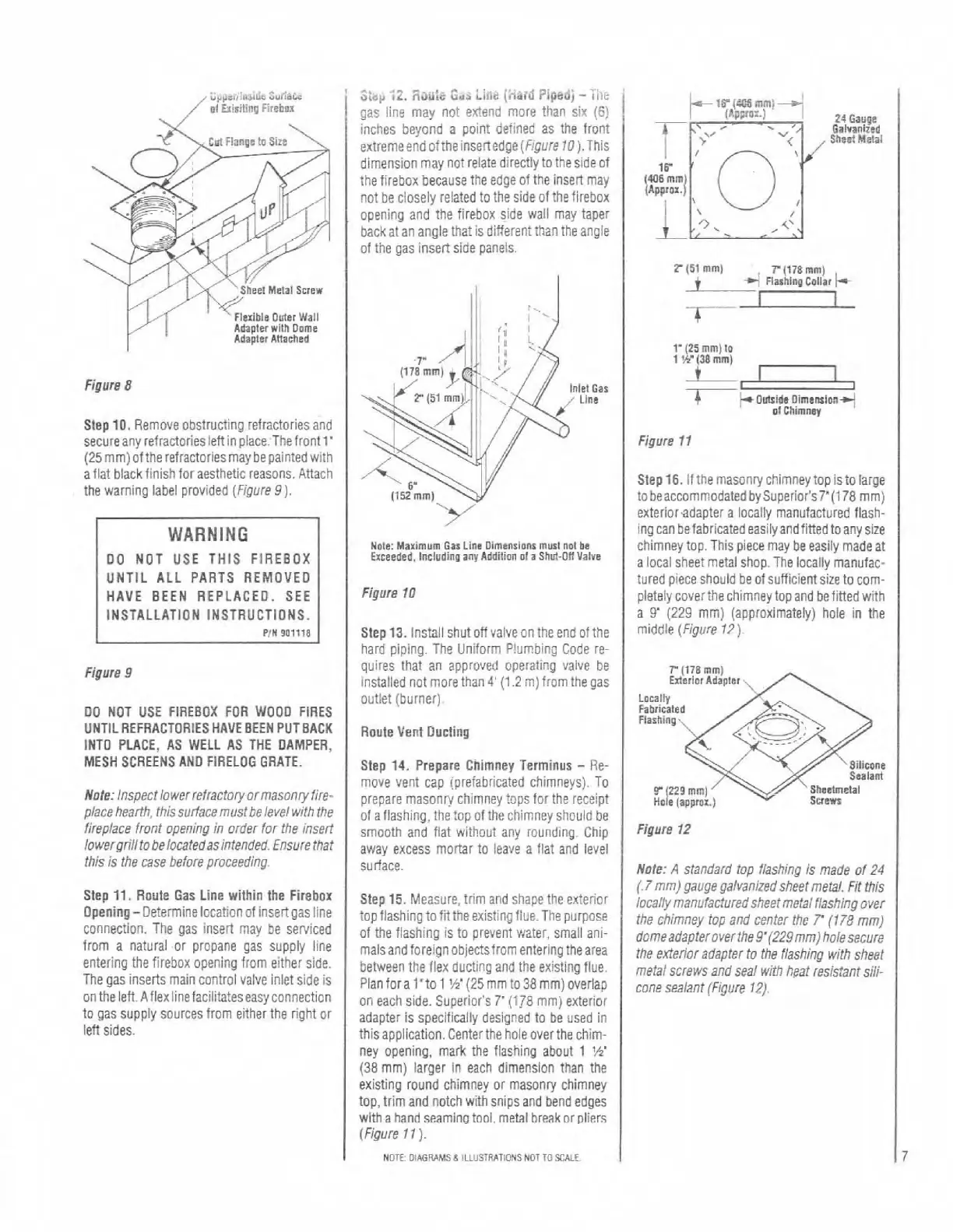

Figure

8

Steo

10.

Remove obstructino refractoriesand

secureany

refractoriesieftinplace.~hefrontl'

125

mmlof the refractoriesmav be oainted with

;flat black finish for aesthetic'reaions. Attach

the warning label provided

(Fipure 9).

WARNING

DO NOT USE THIS FIREBOX

UNTIL ALL PARTS REMOVED

HAVE BEEN REPLACED. SEE

INSTALLATION INSTRUCTIONS.

PIN

901118

Figure

9

DO NOT USE FIREBOX FOR WOO0 FIRES

UNTILREFRACTORIES HAVE BEEN PUT BACK

INTO PLACE, AS WELL AS THE

DAMPER,

MESH SCREENS AN0 FIRELOG GRATE.

Note: Inspect lowerrefractory or masonry fire-

place hearth, this

surfacemust be level with the

fireplace front opening in order for the

insert

lowergrillto belocatedasintended. Ensure that

this is the case before proceeding.

Step

11.

Route Gas Line within the Firebox

Opening- Determine location of insert gas iine

connection. The gas

insert may be sewiced

from a naturai or propane gas supply iine

entering the firebox opening from either side.

The gas inserts main control vaive inlet side is

on the

iett

Aflexiinefacili'ateseasy

connection

to gas supply sources from either the right or

left sides.

gas line may not extend more than sir

(6)

1

inches bevond a ~olnt defined as the front

/

extremeend oftheinsertedge

(Flgure

10).This

dimension may not relate directly to the side of

the firebox because the edge of the insert may

not be closely related to the side of the firebox

opening and the

tirebox side wall may taper

back at an angle that is different than the angie

of

the gas insert side panels.

Nole:

Maximum

Oat

Line Dimensions

murl

nol

be

E~ceeded,

locludinn

any

Addition

ol

a

Shul-OW

Valve

Figure

10

Step

13.

Install shutoff valve on the end of the

hard piping. The Uniform

P!urnjing Code re-

quires that an approved operating valve be

instailed not

morethan

4'

(1.2

m)from the gas

outlet (burner).

Route

Vent Ducling

Step

14.

Prepare Chimney Terminus

-

Re-

move vent cap (prefabricated chimneys). To

prepare masonry chimney

tops for the receipt

of a tiashing, the

topof the chimney shouid

be

smooth and flat wiihout any round~ng. Chip

away excess mortar to

leave a flat and level

surface.

Step

15.

Measure, trim and shape the exterior

top flashing

tofittheexistingflueThe purpose

of the flashing is to prevent water, small ani-

mals and

foreignobjectsfrom entering the area

between the flex ducting and the existing flue.

Plan fora

l'to

1

W(25

mm to38 mm) overlap

on each side. Superior's

7

(178

mmj exterior

adapter is specifically designed to be used in

thisapplication. Centerthe holeoverthe chim-

ney opening, mark the flashing about 1

'h'

(38

mm) larger in each dimension than the

existing round chimney or masonry chimney

top, trim and notch with snips and bend

edges

witha hand seaming tool. metal hreaknrpliers

(Figure

77).

NOTE:

OIAGMMS

6

ILLUS1RATIONS

NOT

TO

SCALE

24Gayge

Oalvan~red

Shre!

Metal

P

(51

mm)

7(178mm)

+

4,

Flashing

c0liariw

1'

(25

mm)

lo

1

W(38

mm)

4

~O~ideOimemionj

01

Chimney

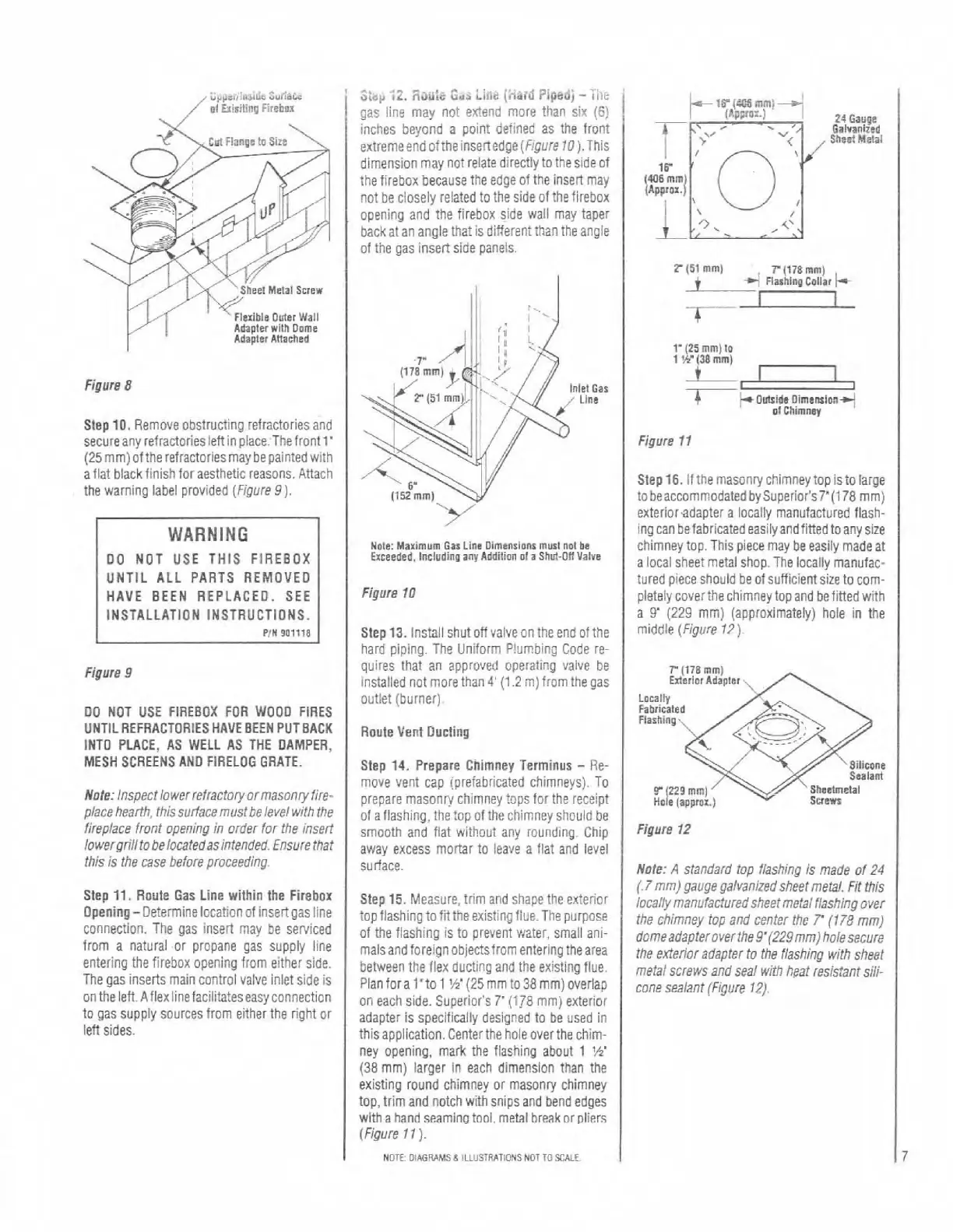

Figure

11

Step

16.

If the masonry chimney top isto large

to beaccommodated

bySuperior's7'(178

mmi

exterior.adapter a locally manufactuied flash:

ina can

befabricatedeasilvandfined

toanvsize

"

,~

~

chimney top. This piece may be easily made at

a local sheet metal shop. The locally manufac-

tured piece should

beof sufficientsizeto com-

pletely

coverthe chimney top and befitted with

a

9'

(229

mm) (approximateiy) hole in the

middle

(Figure

17).

r

(178

mm)

Mcrior Adapter

Locally

Fabricate@

Flashing.

..--.-

Silicone

Sealant

k

n9mm]

Shaahnelal

"ole

(a~prar.)

Svewt

Figure

12

Note:

A

standard top flashing Is made of

24

(7

mm) gauge galvanized sheet meal.

Fit

this

locally

manufac!uredsheetmetalflashing

over

the chimney lop and center the

7'

(1

78

mm)

domeadapterover the9'(229mm) holesecure

the exterior

adapler to the flashing with sheet

metal screws and seal with

heat resistant sili-

cone sealant (Figure

12).

Loading...

Loading...