F2s1jes*

Rule

Gas vent mps that are located

8'

(2.4 mi or

more from a

poltion of a building which ex-

tendsatanangle greaterthan 45°upwardfrom

the horizontal may terminate in accordance

with Table

1,

provided that in no case shall any

discharge opening on the cap be less than 2'

(610 mm) horizontally from the roof surface.

Prepare

Gas

Insert lor tnstallation

Step

1.

inspect the gas insert for any signs ~f

shipping damage. Look for bent or damaged

sheet metal components, check glass for

scratches and chipping. Inspect the gas insert

for any visual defects,

loose or missing parts.

Make sure the gas insert is compatible with

your gas type.

I

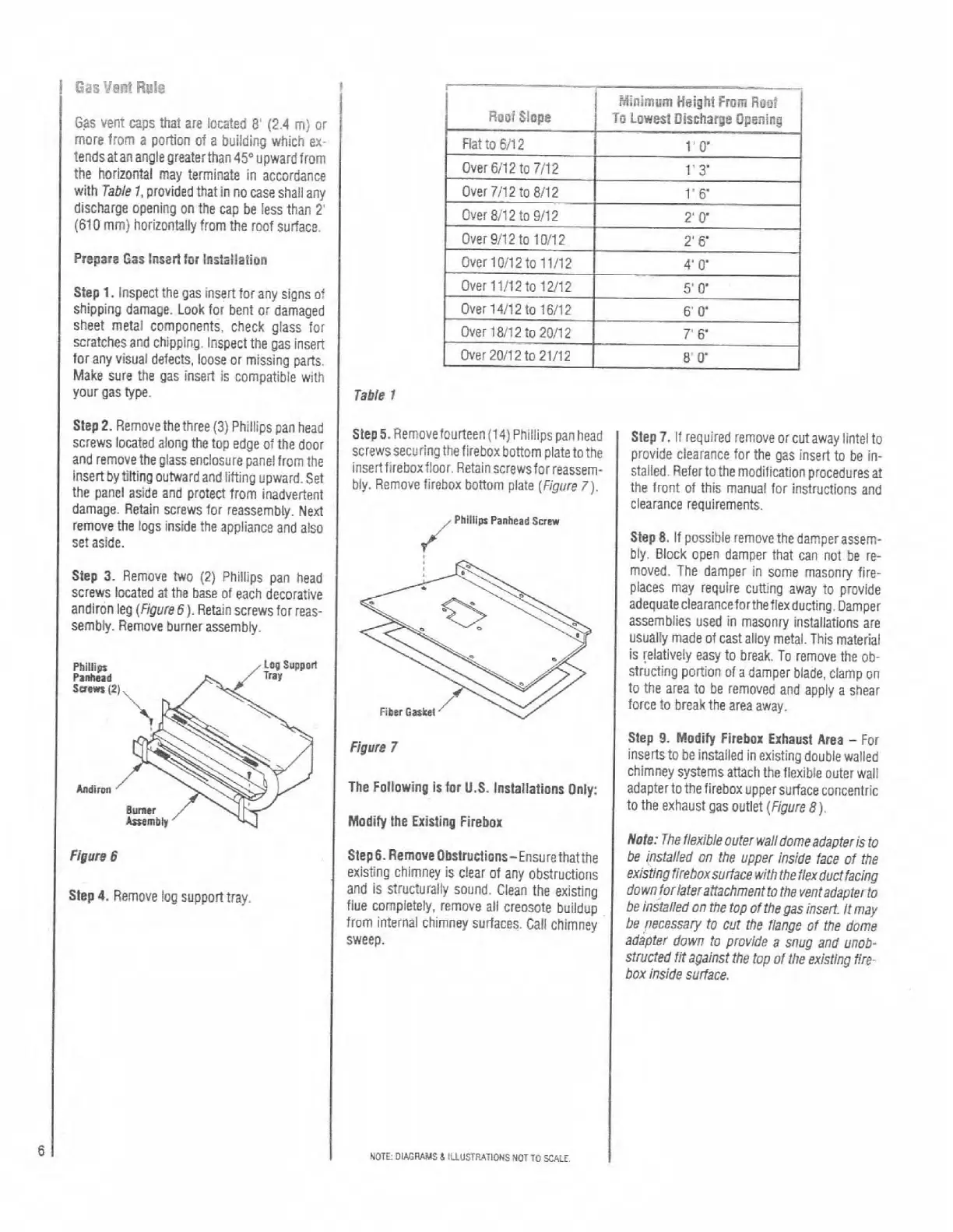

Table

1

Rooi Slope

c

Over 811 2 to 911 2

I

2'

G'

Hlinimum

Height

From

Roo?

To

Lowest Discharge Opening

Flat to 611 2

Over

6/12 to 7112

Over 711

2

to 811 2

1

G'

1'

7

1

'

fi'

- -

I

0ver14112to1fi11~

I

fi'

n'

i

Over 911 2 to 1011

2

Over10112to 11112

Over11!12to12/12

1

Over 1811

2

to 2011

2

1

7'

6'

-

I

-

2'

6'

4'

0'

Y

n'

I

Over 20112 to 21/12

1

8'

0'

set aside.

I

I

Step

2.

Remove the three

(3)

Phillips pan head

screws

located

the

lop edge

Of

the

door

and wnove the glass enclosure Panel from the

insert by tiking outward and lifting upward. Set

the panel aside and protect from inadvertent

damage. Retain screws for reassembly. Next

remove the

logs inside the appliance and also

Step

3.

Remove two

(2)

Phillips pan head

screws located at the base of each decorative

andiron leg

(Fipure6). Retain screwsfor reas-

sembly. Remove burner assembly.

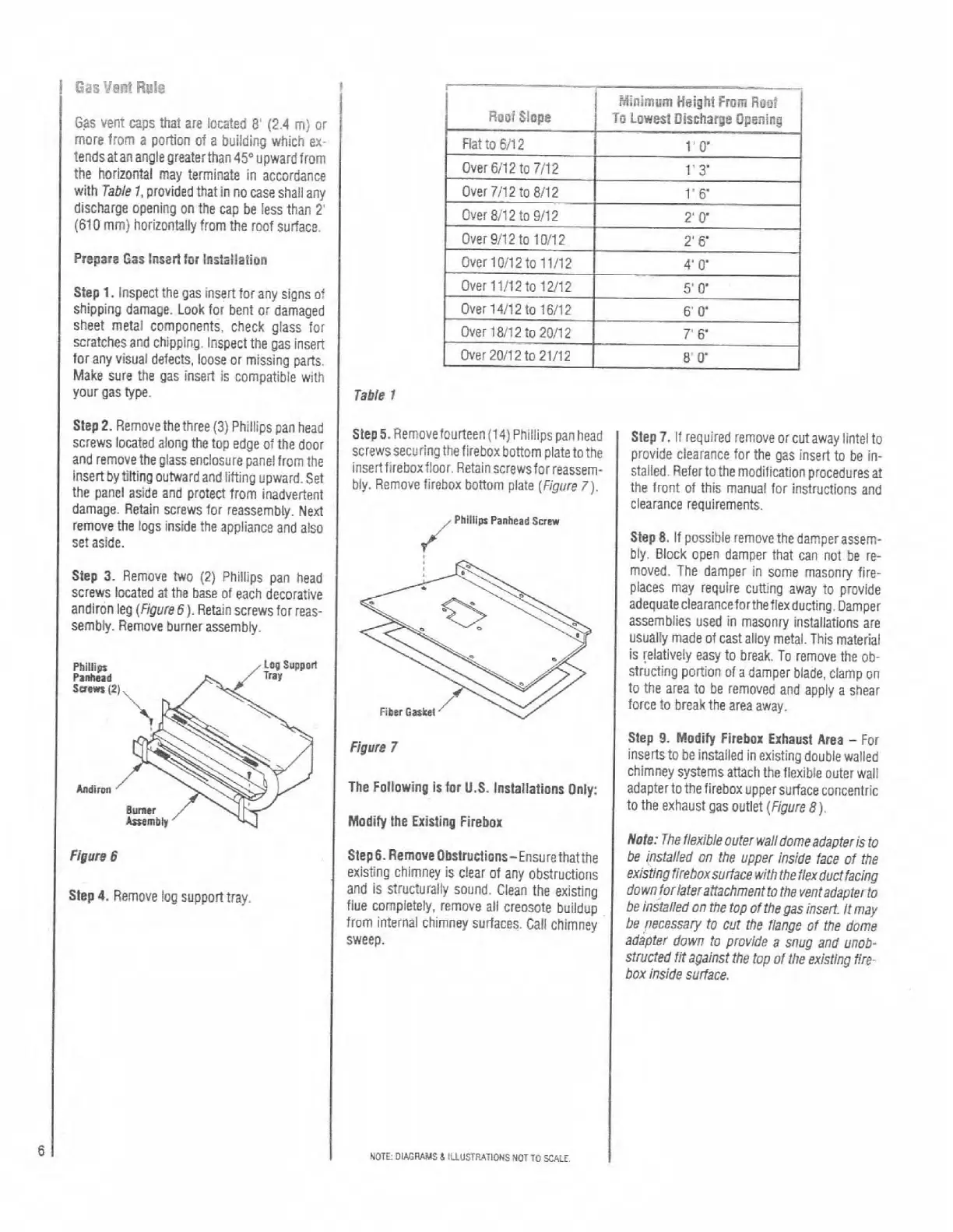

steps. Removefourteen (14) Phillips panhead

screwssecuringthefireboxbottom

platetothe

insertfireboxfloor. Retain screwsforreassem.

bly. Remove firebox bottom

(~i~,,~~

7),

/

Phllllg Panhead

Scra

Figure

6

Step

4.

Remove !og support tray.

Figure

7

The Fallowing Is for

U.S.

lmtallations Only:

Modify the Existing Firebox

I

Step

6.

Remove Obstructions-Ensurethatthe

existing chimney is clear of anv obstructions

I

and is structurally sound. clean the exisin;

flue completely, remove all creosote buildup

from internal chimney surfaces. Call chimney

sweep.

Step

7.

If required remove or cut away lintel to

provide clearance

for the gas insert to be in-

stalled.

Refertothe modification procedures at

the front of this manual for instructions and

clearance requirements.

Step

8.

If possible remove the damperassem-

biy. Block open damDer that can not be re-

moved. The damper in some masonry fire-

places may require cutting away to provide

adequateclearancefortheflexducting.

Damper

assemblies used in masonry installations are

usuaily made of cast alloy metal. This material

is [eiatively easy to break. To remove the ob-

structing portion of a damper blade, clamp on

to the area to be removed and apply a shear

force to break the area away.

Step

9.

Modify Firebox Exhaust Area

-

For

insertsto be installed in existing double walled

chimney systems attach the flexibie outer wail

adapterto the firebox upper surface concentric

to the exhaust gas outlet (Figure

8).

Nole:

The flexible outer walldome adapteris to

be installed on the upper inside face of Me

existing

fireboxsurface with the flexductfacing

downforiateraitachment to the ventadapterto

be installed on the top of

thegas insert

it

may

be necessary to cut

Me

flange of the dome

adapter down to provide a snug and unob-

structed fit against the top of the existing fire-

box inside surface.

Loading...

Loading...