REFER TO NATIONAL AND ALL APPLICABLE LOCAL CODES FOR SPECIFIC INSTALLATION REQUIREMENTS.

1.

The boiler should be mounted on a solid, level foundation.

2.

The boiler should be located with suitable clearances, refer to page 3 and Code requirements.

NOTE:

Allow minimum of 21 inches clearance in front of door for servicing of heating elements.

ALL PIPING SHOULD BE INSTALLED BY A QUALIFIED LICENSED PLUMBER IN ACCORDANCE WITH

NATIONAL AND LOCAL CODES.

1.

When water feed is other than pump type the water

supply pressure must be 10 psig greater than boiler oper-

ating pressure to assure water supply maintains proper

water level in the boiler. Insufficient water levels can result

in improper boiler operation. (Keep feed water valves

open at all times during normal operation.)

2.

If pump and boiler are plumbed within 30 feet (pipe

length) a minimum of 2 check valves are required to

avoid damage to pump.

Piping

Sussman Boilers

Installation, Operation & Maintenance Manual

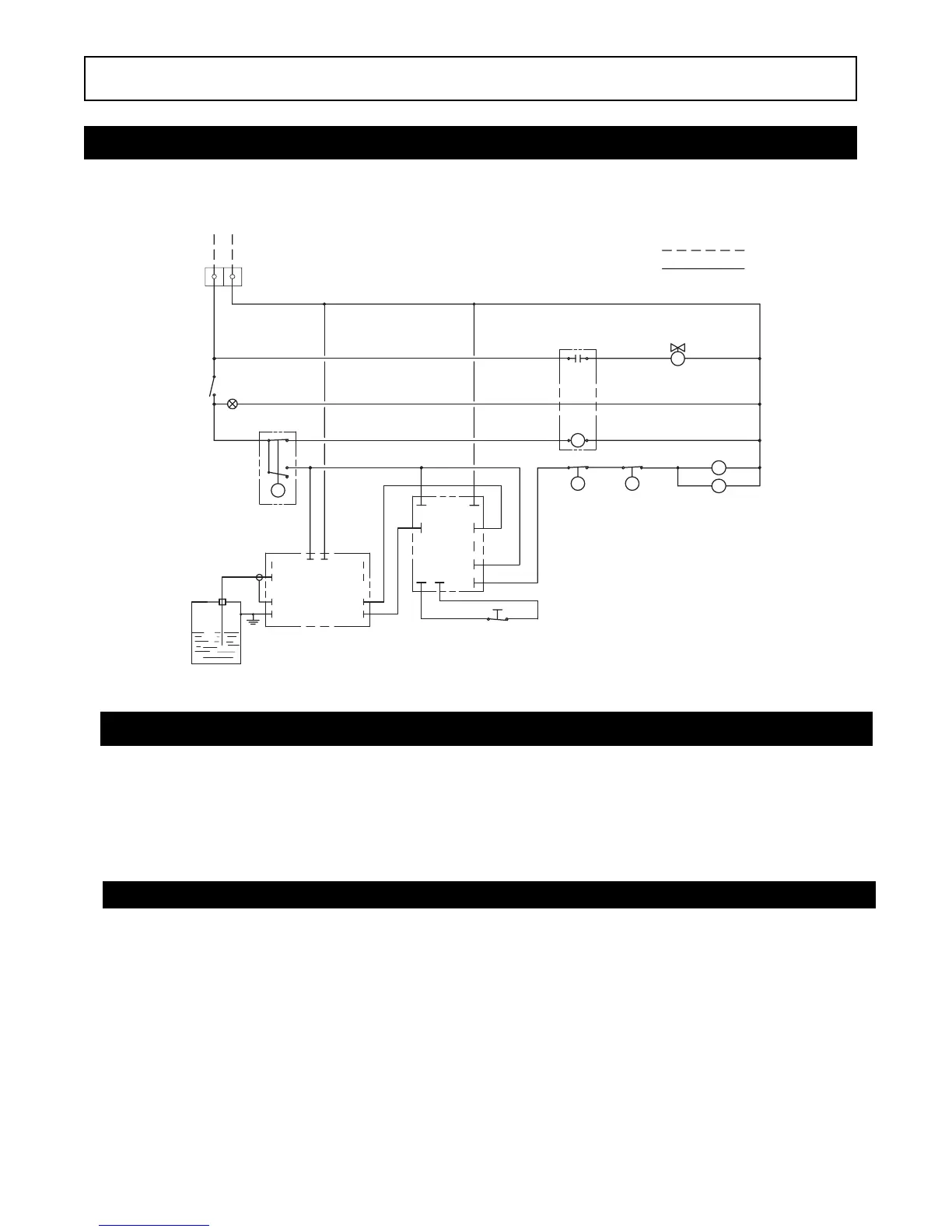

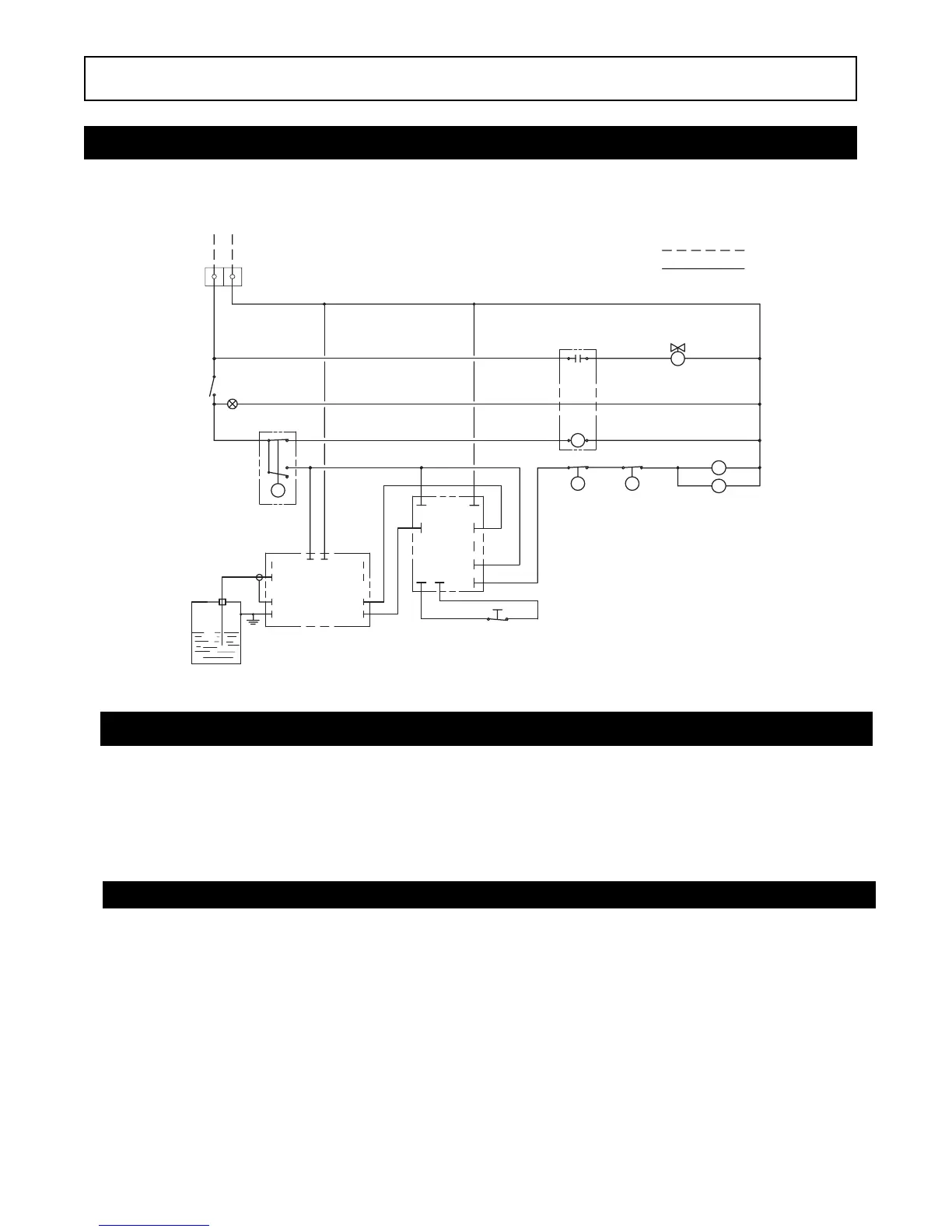

Wiring Diagram Control Circuit

8

RELAY

FIELD WIRING

FACTORY WIRING

PILOT

LIGHT

L

AUTOMATIC

PRESSURE

CONTROL

AUX LWCO BOARD

MANUAL RESET

BOILER SHELL

PROBE

GUARD

GROUND

LWCO

LWCO

HIGH LIMIT

PRESSURE

CONTROL

LIQUID

LEVEL

CONTROL

ON-OFF

SWITCH

CONTROL

TERMINAL

BLOCK

120V 1PH

INPUT

SOLENOID VALVE

C1

C4

CONTACTORS

P2

L1 L2

LO

L1 L2

LLCO

RESET

G

NC

COM

NO

P1

R

S

L N

SSB Electric Boilers with Manual Reset, Auxiliary Low Water Cutoff

3.

Connect steam line with customer supplied outlet valve

to boiler steam outlet.

4.

Provide for boiler drain connection, a daily blowdown is

required. A "Blowdown Separator Tank" may be neces-

sary, check with local code.

5.

Safety valve shall be plumbed according to local code.

NOTE:

The safety valve shall not be plumbed with a line

sized less than the outlet size of the safety valve.

Loading...

Loading...