CHASSIS 5-7

INSPECTION AND DISASSEMBLY

SPEEDOMETER GEARBOX DUST SEAL

Inspect the lip of the dust seal for damage.

TIRES

! 5-54

FRONT WHEEL

Make sure that the wheel runout (axial and radial) does not ex-

ceed the service limit when checked as shown. An excessive

amount of runout is usually due to worn or loose wheel bearings

and can be corrected by replacing the bearings. If bearing replace-

ment fails to reduce the runout, replace the wheel.

&&

&&

& Wheel rim runout

Service Limit (Axial and Radial): 2.0 mm

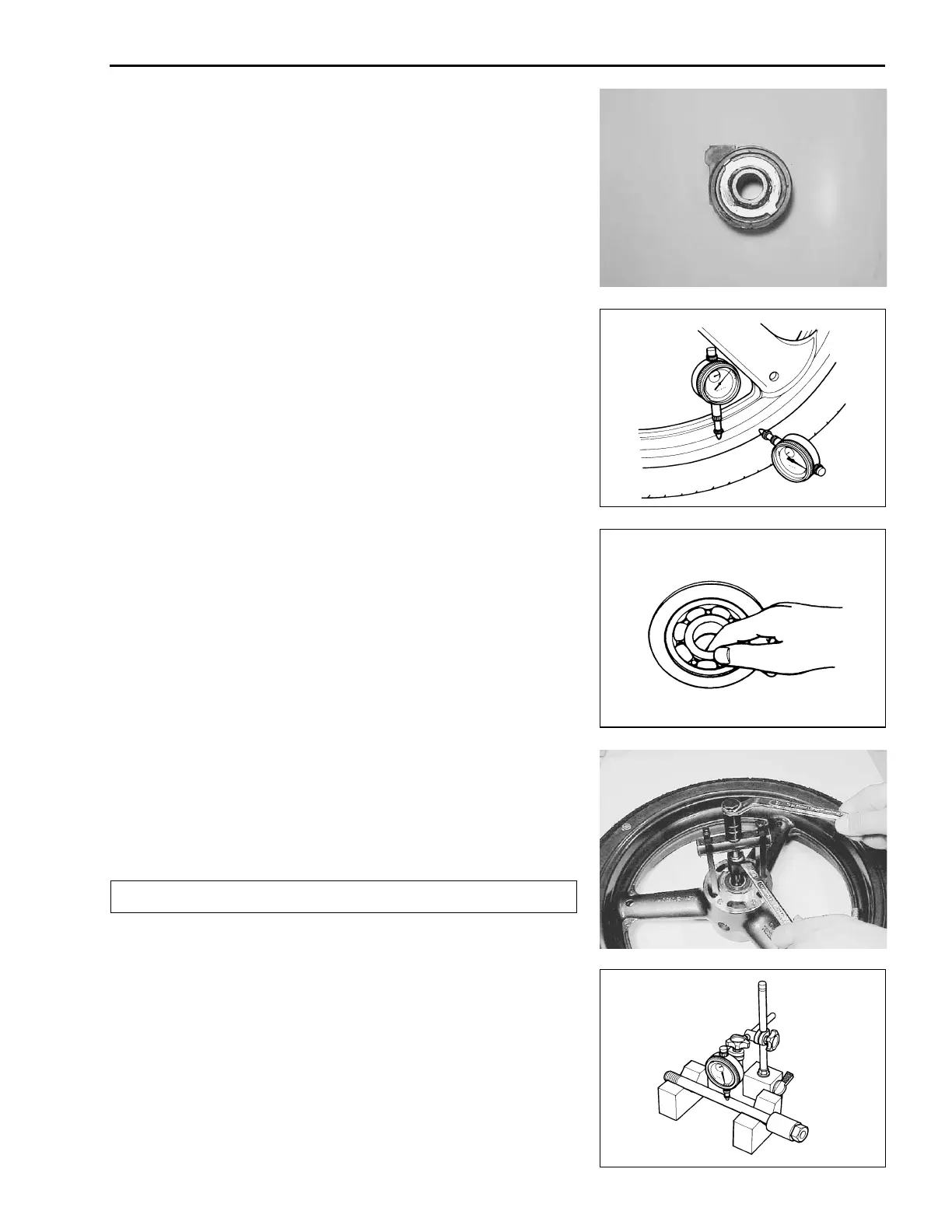

WHEEL BEARINGS

Inspect the play of the wheel bearings by hand while they are in

the wheel. Rotate the inner race by hand to inspect it for abnormal

noise and smooth rotation.

Replace the wheel bearings if there is anything unusual.

Remove the wheel bearings as follows:

• Remove the bearing using the special tool (

φ

20 mm).

''

''

' 09921-20220: Bearing remover set

NOTE:

If no abnormal noise, bearing removal is not necessary.

%

The removed bearings should be replaced with new ones.

FRONT AXLE

Measure the front axle runout using the dial gauge.

If the runout exceeds the limit, replace the front axle.

''

''

' 09900-20606: Dial gauge (1/100 mm)

09900-20701: Magnetic stand

09900-21304: V-block set (100 mm)

&&

&&

& Front axle shaft runout

Service Limit (Front and Rear): 0.25 mm