46

Operation and maintenance instructions

- Conditions:

- Causes:

•

The setpoint cannot be fullled because the upper or lower limit of the fan’s working zone has been reached

- Eects:

- Conditions:

- Causes:

•

Crucial data from the circuit board has been lost

- Eects:

- Solutions:

•

Try a TOTAL RESET of the data using the advanced setup. If still not resolved, order a new circuit board.

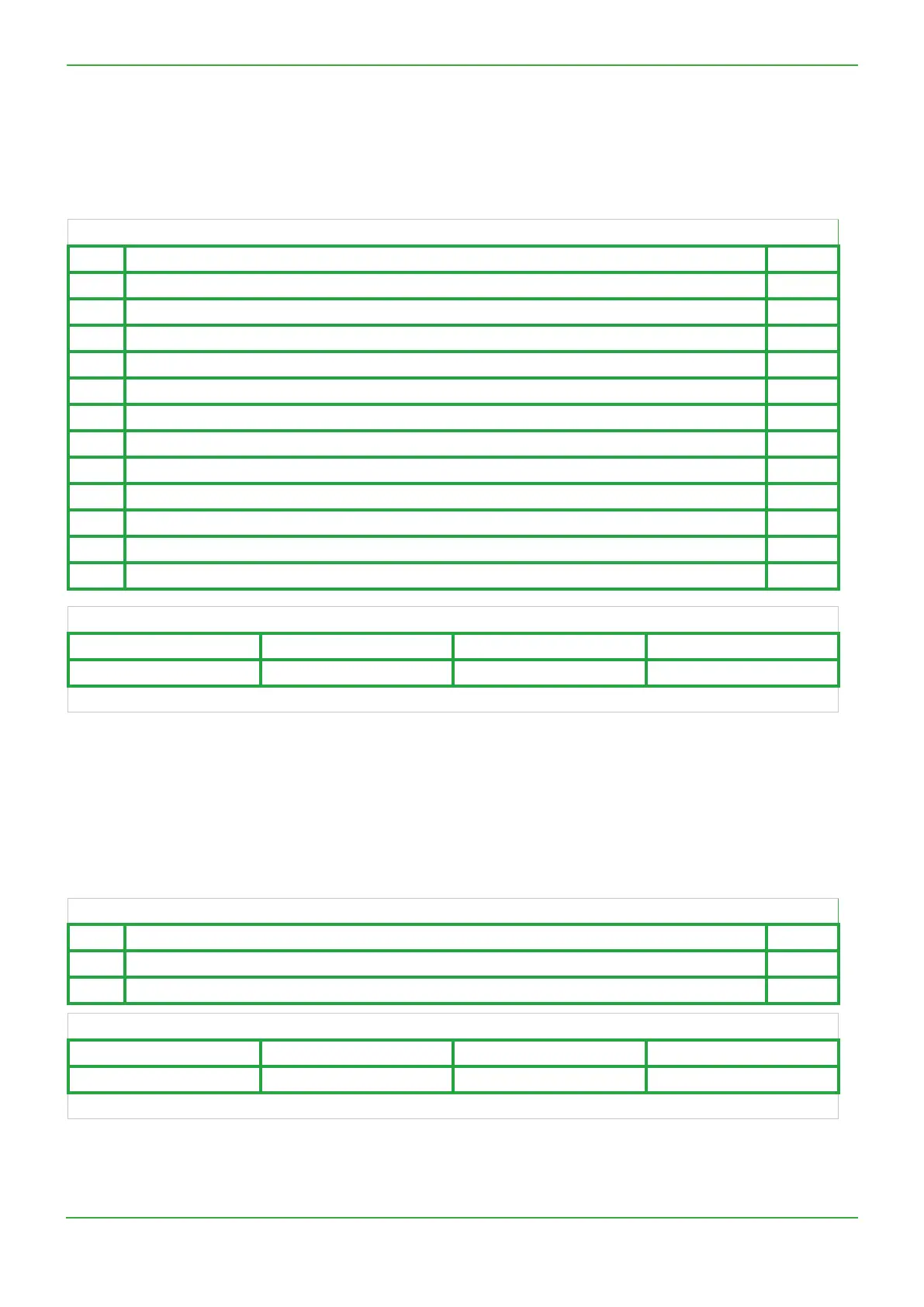

8.4 TYPE 4: ALARM INDICATING THE SYSTEM CANNOT FULFIL THE SETPOINT

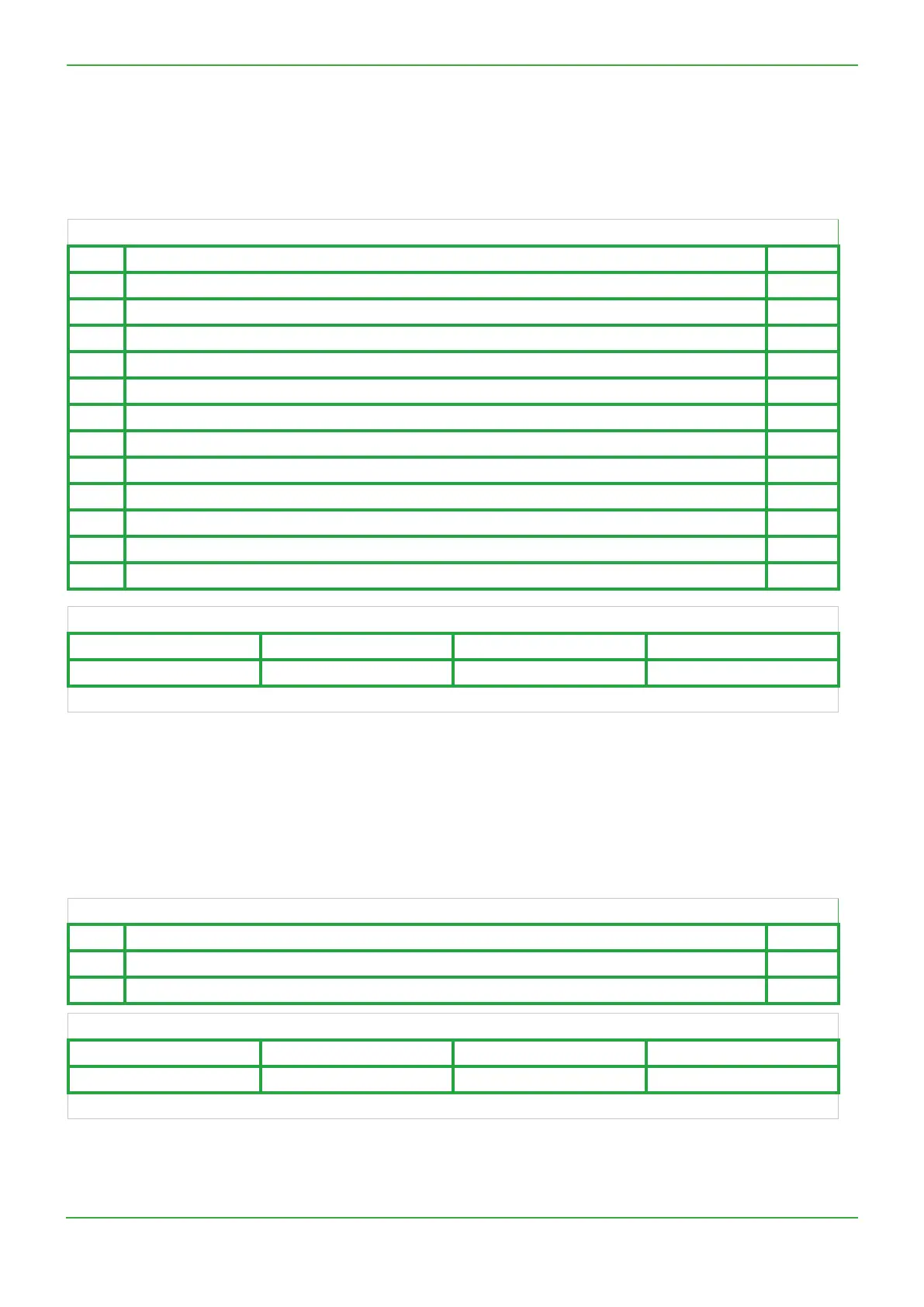

8.5 TYPE 5: ALARM INDICATING A DATA FAILURE IN THE CONTROL CIRCUIT

TAC control board

ALARM OUTPUT AL dPa OUTPUT LED ALARM Fans

/ / ON /

Auto reset: yes

TAC control board

ALARM OUTPUT AL dPa OUTPUT LED ALARM Fans

Alarm status / ON Stopped

Auto reset: no

Displayed on HMI TACtouch

Code Text displayed Level

D.10 Programme Error 3

D.20 Data Error 3

Displayed on HMI TACtouch

Code Text displayed Level

S.11 “Constant Pressure” fan 1 - Measured pressure too high - Minimum air ow reached 2

S.12 “Constant Pressure” fan 1 - Measured pressure too low - Maximum air ow reached 2

S.13 “Constant Pressure” fan 3 - Measured pressure too high - Minimum air ow reached 2

S.14 “Constant Pressure” fan 3 - Measured pressure too low - Maximum air ow reached 2

S.20 “Demand control” fan 1 - Air ow too low - Reduce the pressure on this fan 2

S.21 “Demand control” fan 1 - Air ow too high - Minimum limit of the motor reached 2

S.22 “Demand control” fan 2 - Air ow too low - Reduce the pressure on this fan 2

S.23 “Demand control” fan 2 - Air ow too high - Minimum limit of the motor reached 2

S.24 “Demand control” fan 3 - Air ow too low - Reduce the pressure on this fan 2

S.25 “Demand control” fan 3 - Air ow too high - Minimum limit of the motor reached 2

S.34 “Constant Air Flow” fan 3 - Air ow too low - Reduce the pressure on this fan 2

S.35 “Constant Air Flow” fan 3 - Air ow too high - Minimum limit of the motor reached 2

Loading...

Loading...