22

THREADING THE MACHINE

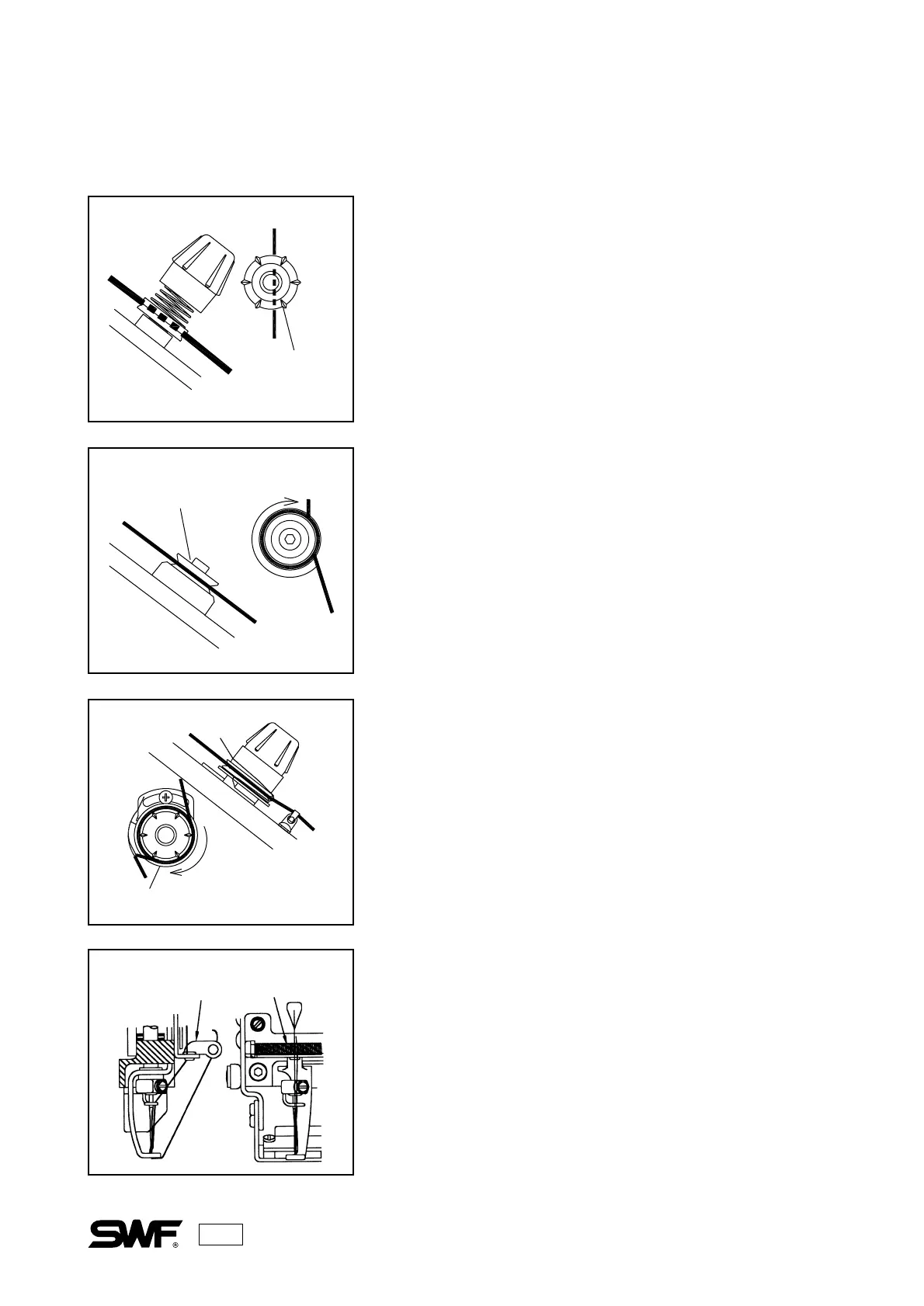

Thread Guide Disk

(Pass through the

middle of shaft)

Wrap the thread around thread guide disk clockwise. Make sure

the thread falls between the tension discs.

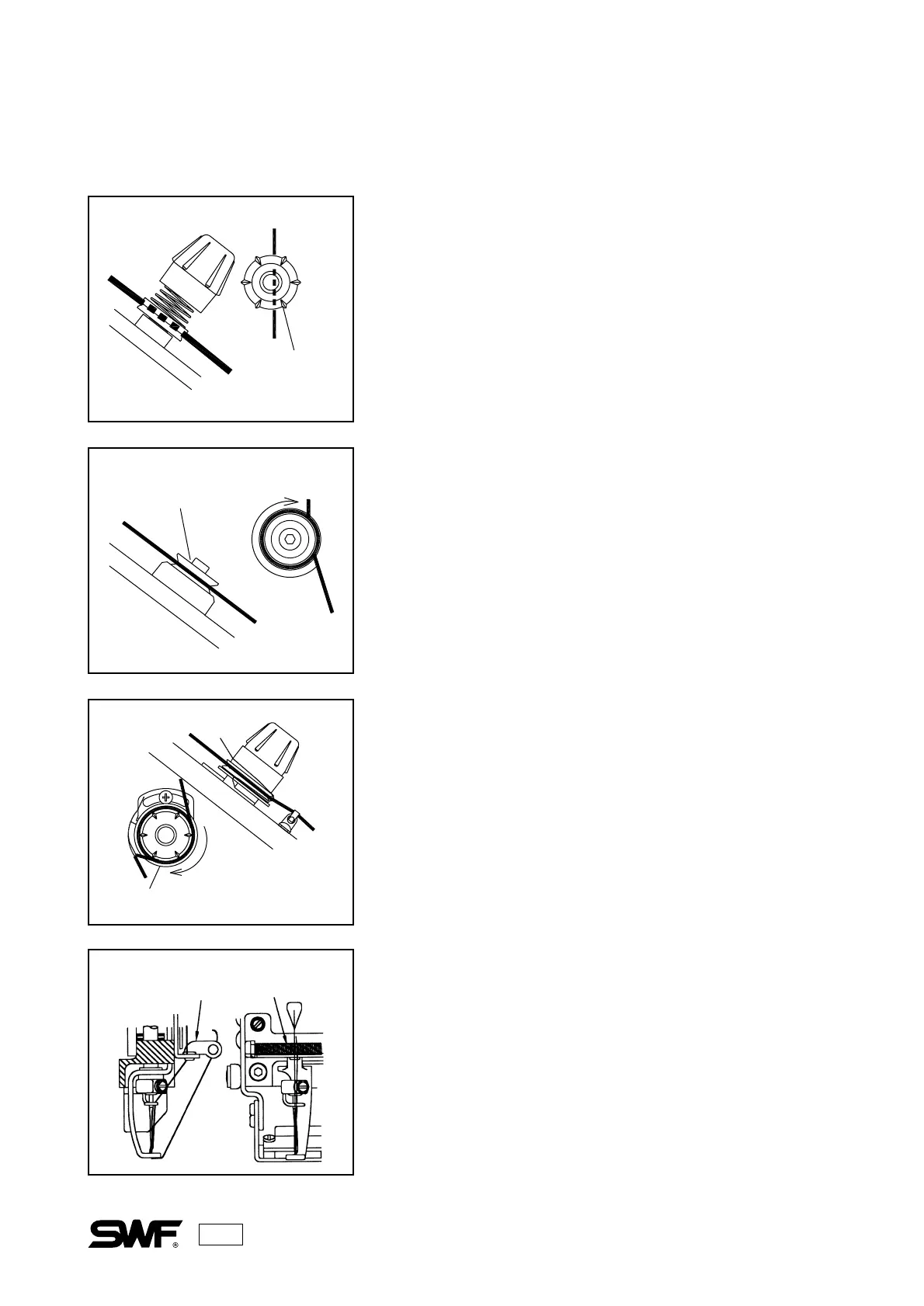

Thread Sensing Roller

One turn

Rotary Tension Disk

Wrap the thread around thread sensing roller one time.

Wrap the thread 1.5 times around the main tensioner in the V-

groove between the rotary tension disks. Pass the thread through

the spiral thread guide, the upper and lower thread guide, up

through the eye of the thread take-up lever, down though the lower

thread guide and then down through the lower thread guide.

Thread Guide

(Lower)

Thread

Hook Spring

Place the upper thread between the upper thread holder ball of the

thread guide (lower).

One and

half turn

Loading...

Loading...