35

RELATIONSHIP BETWEEN TAKE-UP LEVER AND HOOK

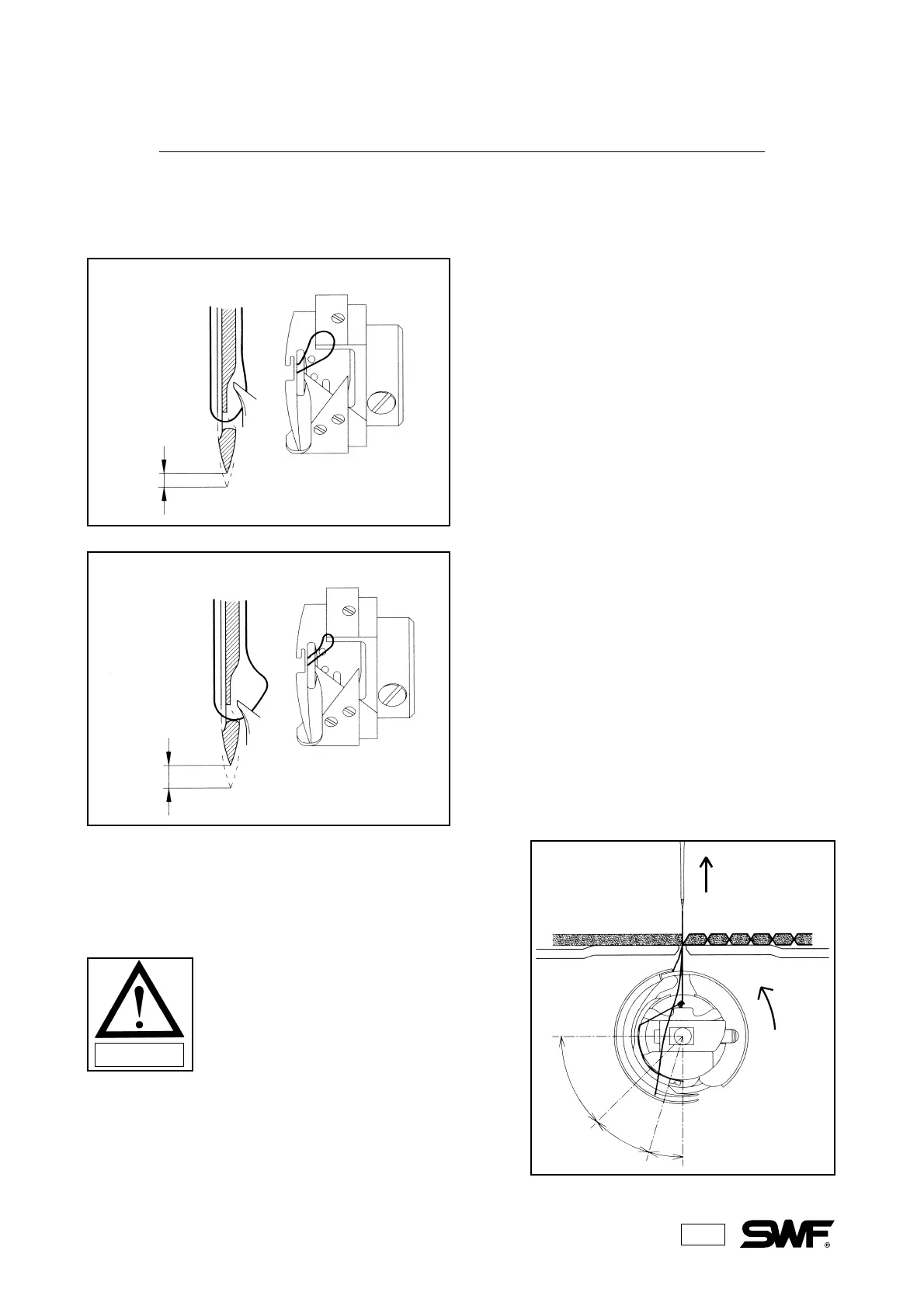

The following pictures show the location of hook when the take-up lever starts to move up from the lower

dead stop (main shaft rotation angle: 295°).

Too

small

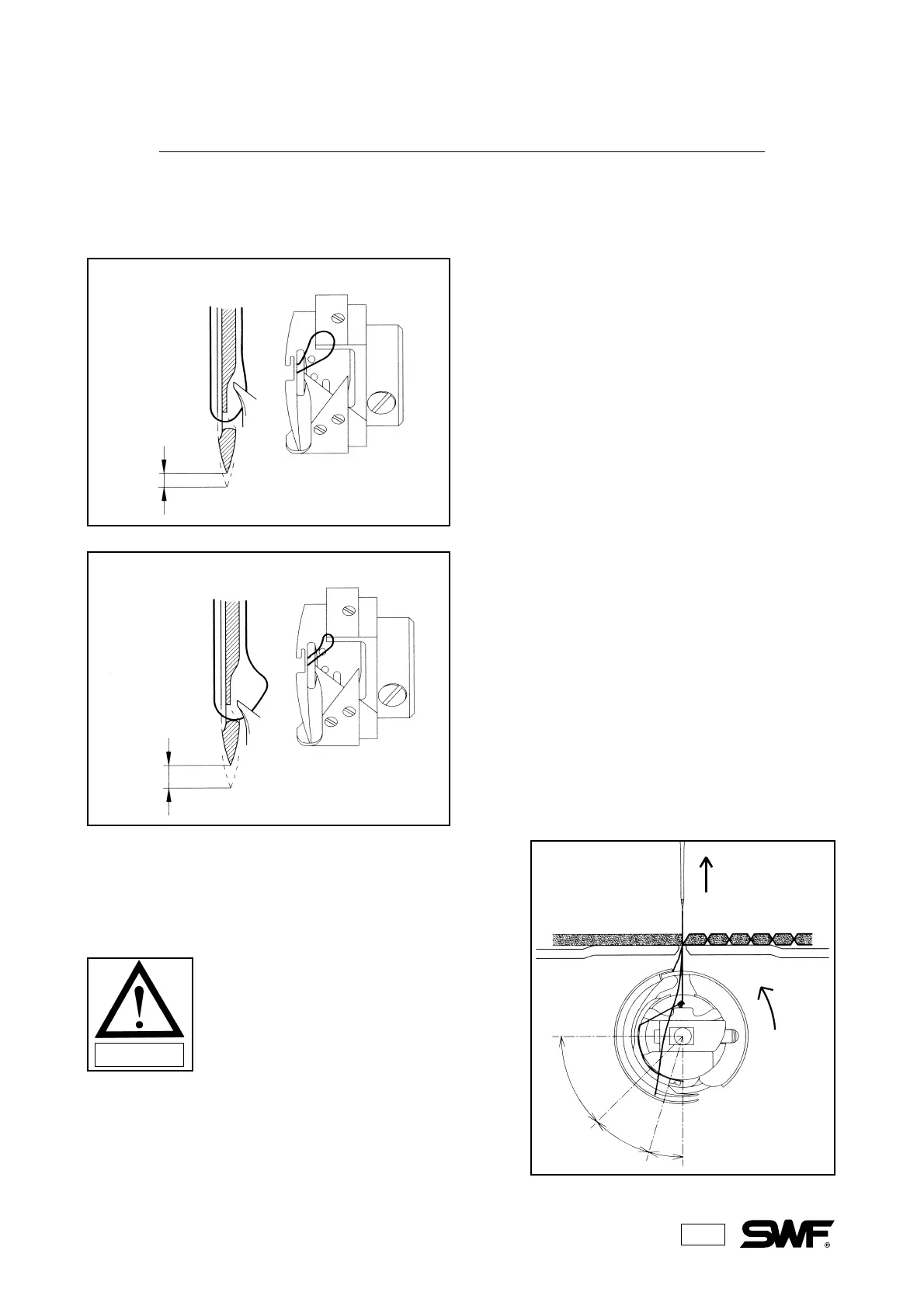

When the hook timing falls in the A range (see

illustration below) the loop will be too small. Stitch

formation will take place faster than the upward

movement of the take-up lever. The thread will be

too loose and looping and skipped stitches will

occur.

If the hook timing falls in the B range (see below),

the hook point will catch the thread when the loop is

too big. This will cause thread breaks since the

upward movement of the take-up lever is faster then

the rate at which the thread comes off the hook.

Too

Large

(B)

(C)

(A)

CAUTION

When the hook timing is correct, the

hook should move within the C range.

In case of fast hook timing

In case of slow hook timing

Loading...

Loading...