23

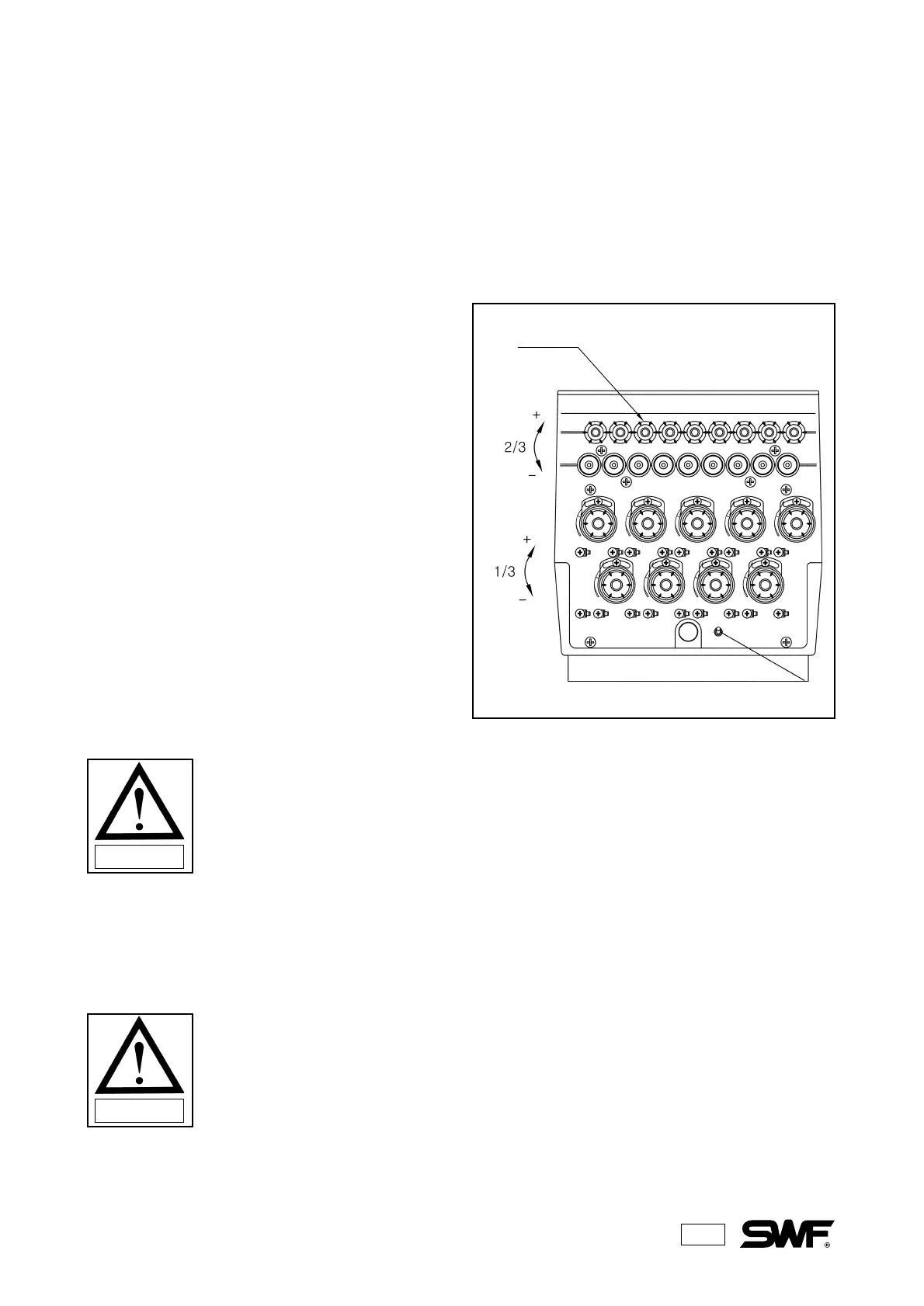

TENSION CONTROL ON UPPER THREAD

Proper tension is an important factor in producing quality embroidery. If the upper tension is too loose,

looping and thread breaks may occur. If the tension is too tight, thread and needle breaks may occur as well

as puckering. A balance of 2/3 upper thread and 1/3 lower thread generally indicates good tension.

1) The upper thread tension is controlled by turning

the adjusting nut on the sub-tensions (pre-

tensioners) and the main tension adjusting

device. Turn clockwise to increase the tension

and counterclockwise to decrease the tension.

2) The sub-tension adjusters or pre-tensioners

should control about 2/3 of the tension while the

main tension adjusting units should handle the

other third. The pre-tensioners should be

adjusted so that the upper thread flows smoothly

through the disks and into the rollers of the main

tension adjusting units. The main tensioners are

used to fine tune the tension.

Sub tension

adjusting

device

Adjusting nut

Main

tension

adjusting

device

3) After the tension is adjusted on both the pre-tensioners and the main tension adjusting units, adjust the

tension settings on the pre-tensioners again if the tension is too light to allow for the upper thread flow.

WARNING

You should have to use some force to pull the thread through the tension units if

adjusted correctly.

The tension should be around 100-120g.

WARNING

Adjust the thread tension according to the type of thread used and target fabric.

Loading...

Loading...