Technical Manual 19

Water Inlet Components (cont.):

Sight Glass:

Connected to the steam tank by two tubes, the sight glass provides a visual

representation of the level of water in the steam tank. It should be about 1/2 to 2/3 full during

normal operation. This is a safety feature which enables the user to ensure that they have

sufcient water levels in their steam system.

Steam Inlet Check Valve:

See Brew tanks check valve description. (Page 17).

Steam Inlet Water Control Valve:

When the upper level probe detects an absence of water, it sends a signal to the CPU to open

this valve and allow water into the steam tank. The water then lls the tank until the

probe grounds out on the water, and the valve is then closed.

Steam Tank Inlet Fill Line: (Dual inlet machines only)

This is the incoming 3/8” steel braided line which supplies the steam tank with water.

Vacuum breaker:

Allows steam pressure to build above atmospheric pressure. As the element heats the water

in the steam tank, the pressure from the steam pushes an internal rod and o-ring up, sealing

the steam inside the tank. Pressure continues to build until the temperature probes sense

the temperatures are to the set points, then keeps this pressure inside for use in heating

milk, maintaining a hot water supply, and pre-heating the brew water in the heat exchanger

tubes.

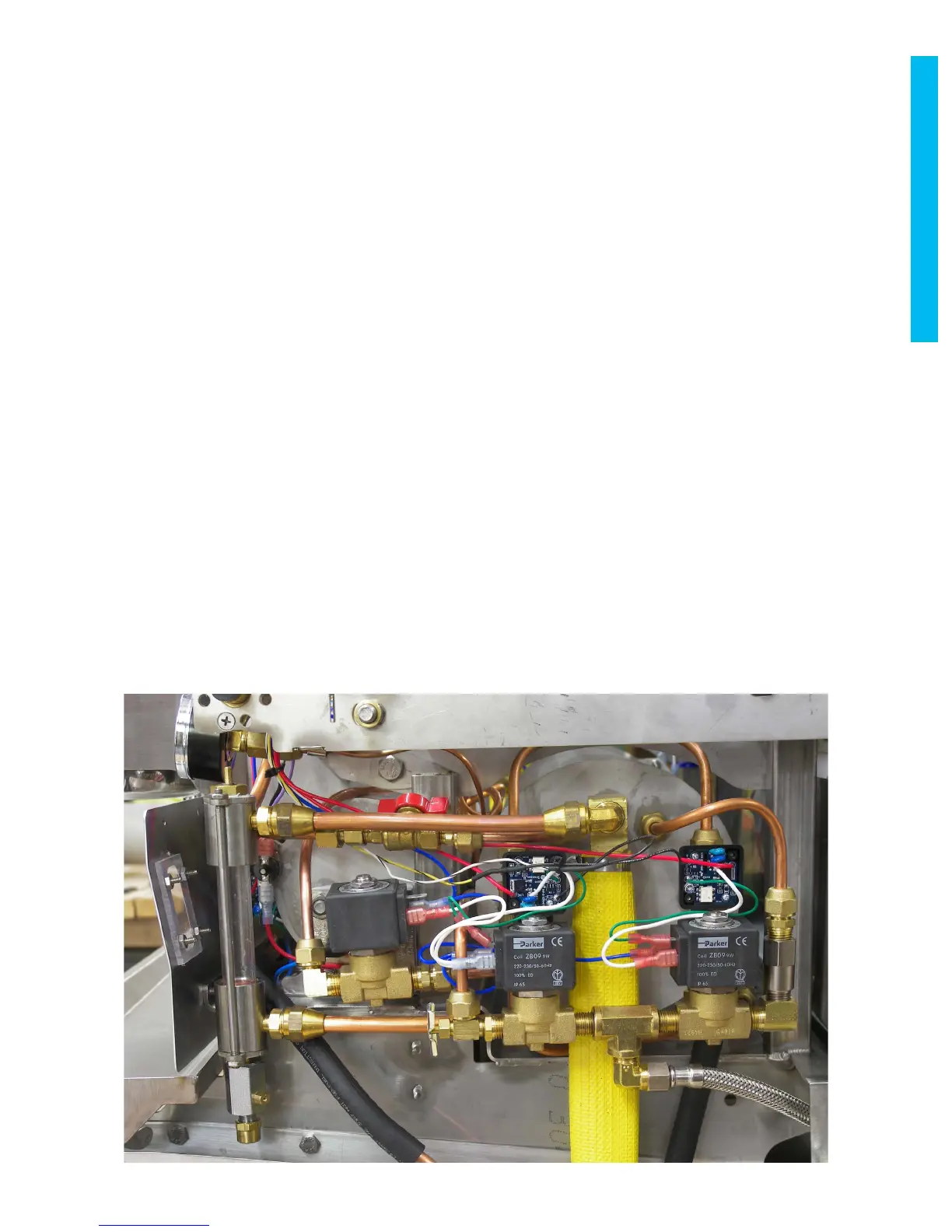

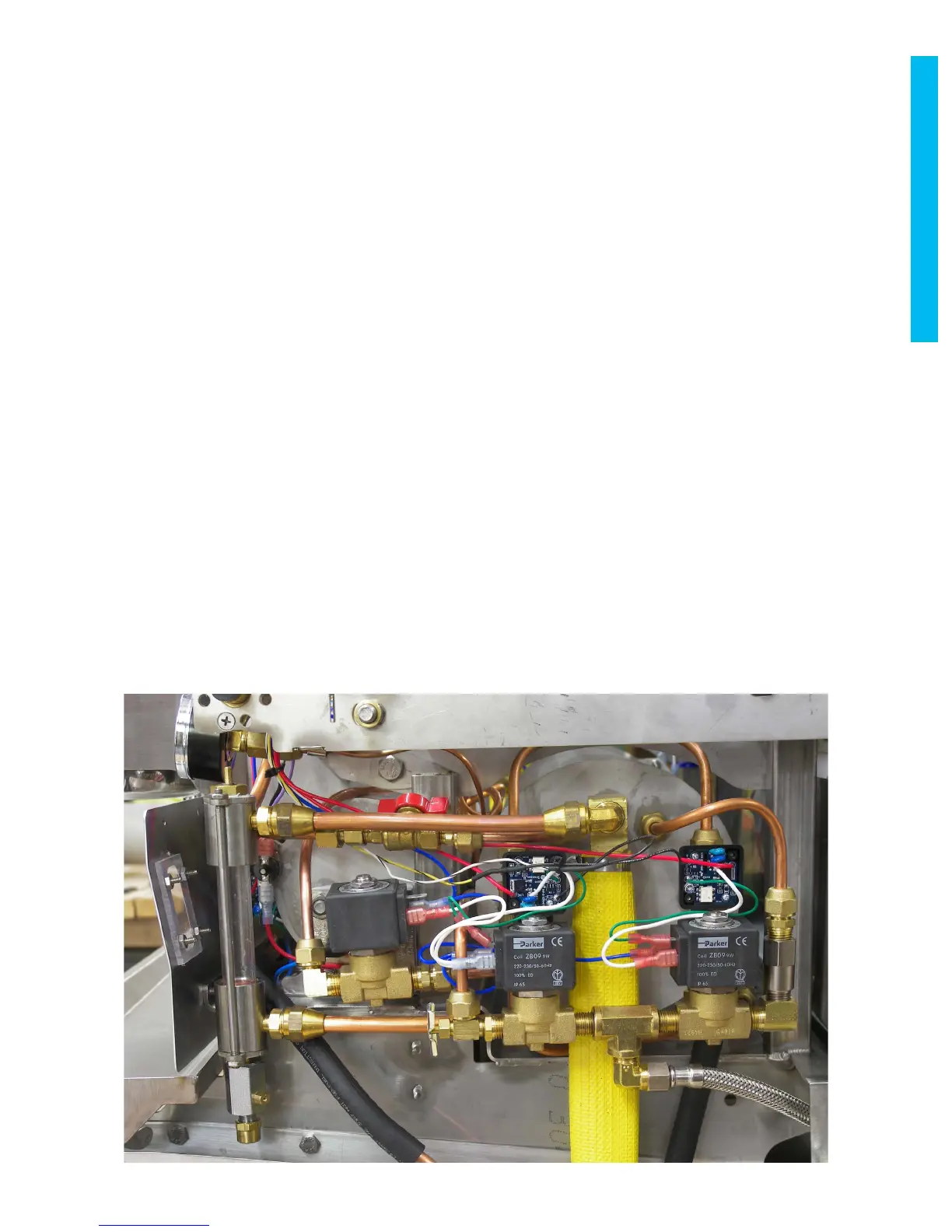

HYDRAULIC SYSTEM

2011 2 Group Cyncra Inlet (right) side

Loading...

Loading...