Technical Manual 20

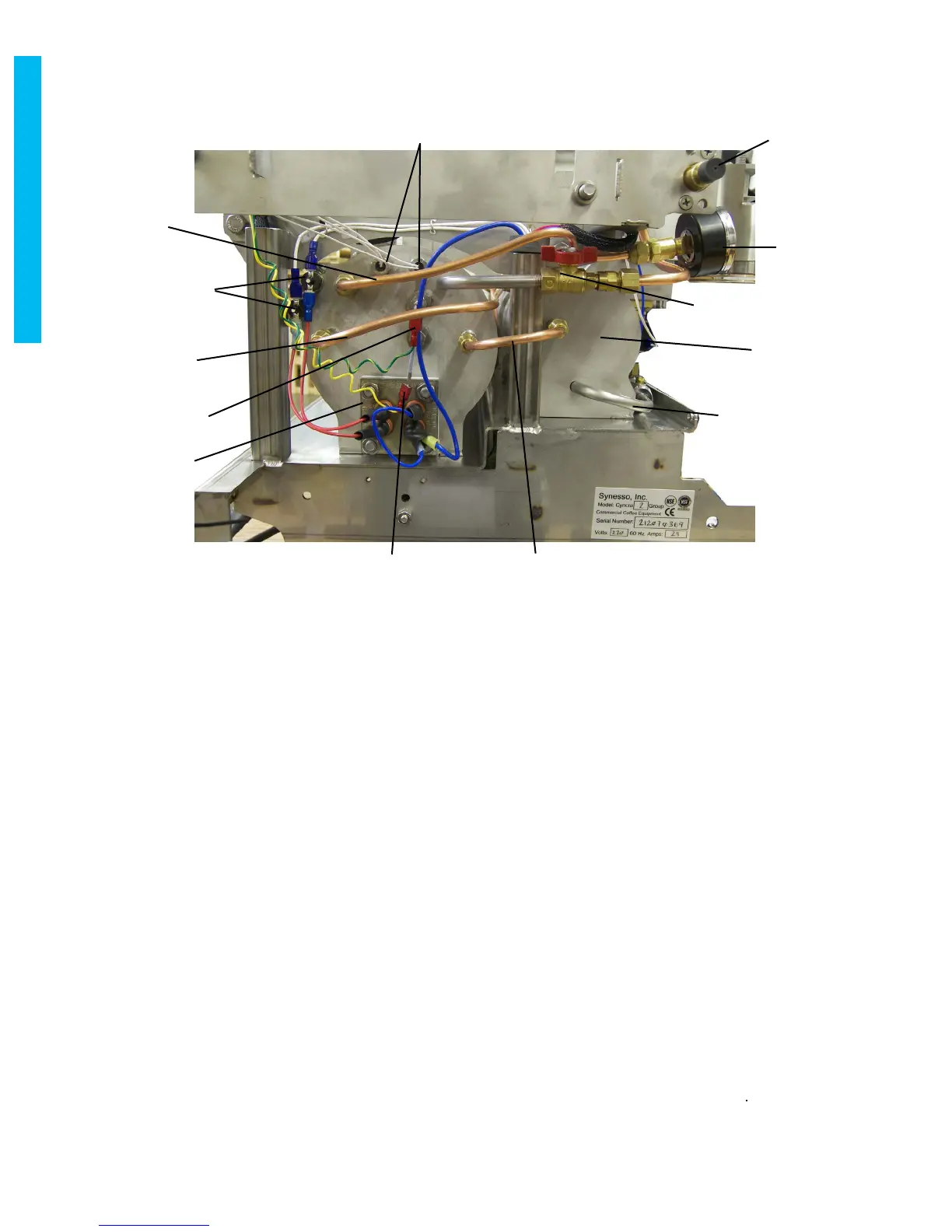

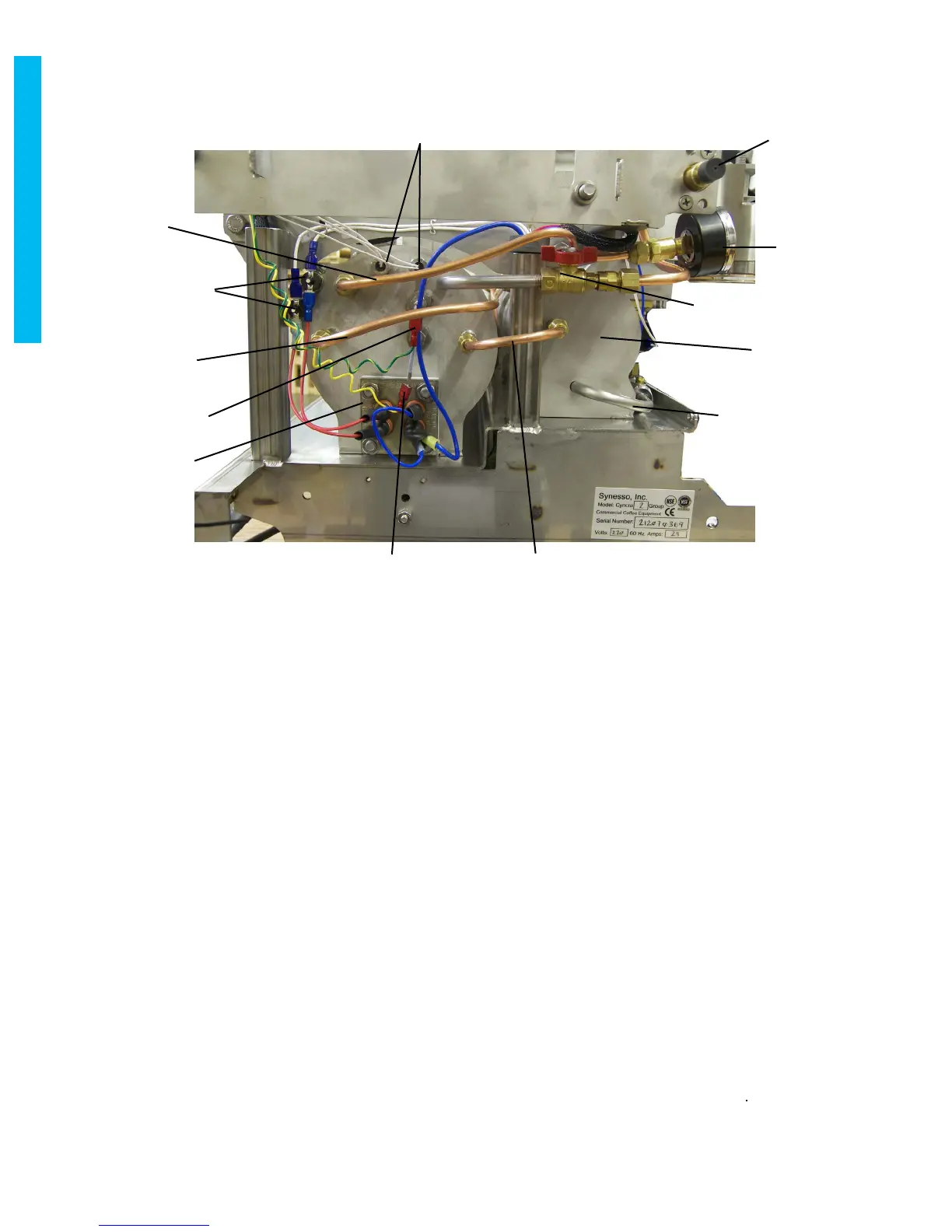

Major Components of the Water Outlet (Left) Side

Steam

actuator

rod

1st position brew

tank ll tube

Brew tank

drain tube

Brew tank

Steam shut off valve

Steam

gauge

Steam tank

thermal overload

switches

Upper Level

probe

Heating

element

Low level probe

Steam gauge

tube

Temperature probes

2nd position

brew tank ll tube

1st and 2nd position brew tank ll tubes:

After travelling through the steam boiler, the heat exchangers exit on the left side of the

machine and copper tube (these were stainless steel until serial number 352) deliver the

pre-heated water to the brew tanks.

Brew tank:

Synesso™’s brew tanks are solid stainless steel, welded internally and externally in order to be

leak-proof and thermally stable. Each brew tank has its own isolated system from the water

inlet. This allows the user to set different temperatures on each group, as well as function

without a group in the system if something has gone wrong with a group. There is a 3-way

brew valve which controls the ow of water to the group head.

Brew tank drain tube:

Each group head is tted with a drain tube to easily drain the tank. In order to drain a brew

group, remove the pressure from the brew groups by turning off the water, cycling through the

control panel to the Temperature Display screen on menu level 2. Turn the Brew Valve

setting to ON which will allow a small amount of water to run out of the groups. Once the water

stops, select NORMAL on the Brew Valve control line. Remove the 1/2” plug tting on the end

of the drain and attach a 3/8” rubber line to drain the water into the drain pan. Set the Brew

valve control back to ON to completely drain the tank.

Heating element:

A 2-leg incoloy and stainless steel heating element which provides the heat for the steam

boiler. It is controlled by the thermal probes and will be shut off in the case of over-heating

or low water levels.

HYDRAULIC SYSTEM

Cyncra prior to 2011

Loading...

Loading...