8 QSG ti-Series Laser Ver 2.5

ti-Series Laser Quick Start Guide

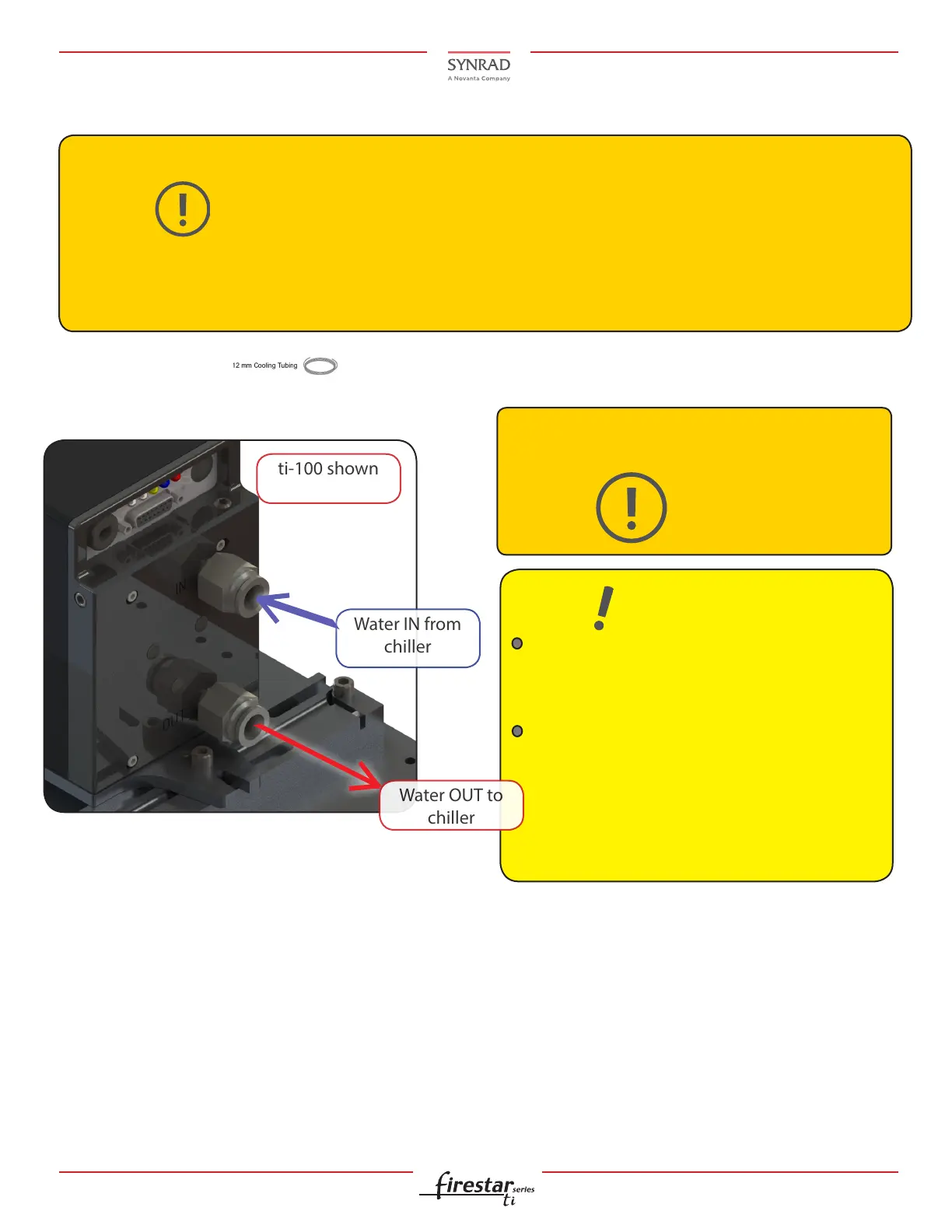

6. Locate the Ship Kit ( ) Cooling quick-disconnect ttings and 1/2 inch polyethylene tubing. See your lasers

cooling interface in the gure below.

Caution

Possible

Equipment

Damage

Operating the laser with a coolant temperature below the dew point of the sur-

rounding air may cause condensation to occur that will damage the laser!

The setpoint temperature MUST be maintained above the dew point temperature. Use

distilled water as the coolant. If glycol is necessary, add no more than 10% by volume.

When filling your chiller, use at least 90% distilled or tap water by volume. If you must

use glycol, do not add more than 10% by volume. See the technical reference chapter in

the Series 48 Operation Manual for the dew point table and cooling specifications.

Cooling (Connued):

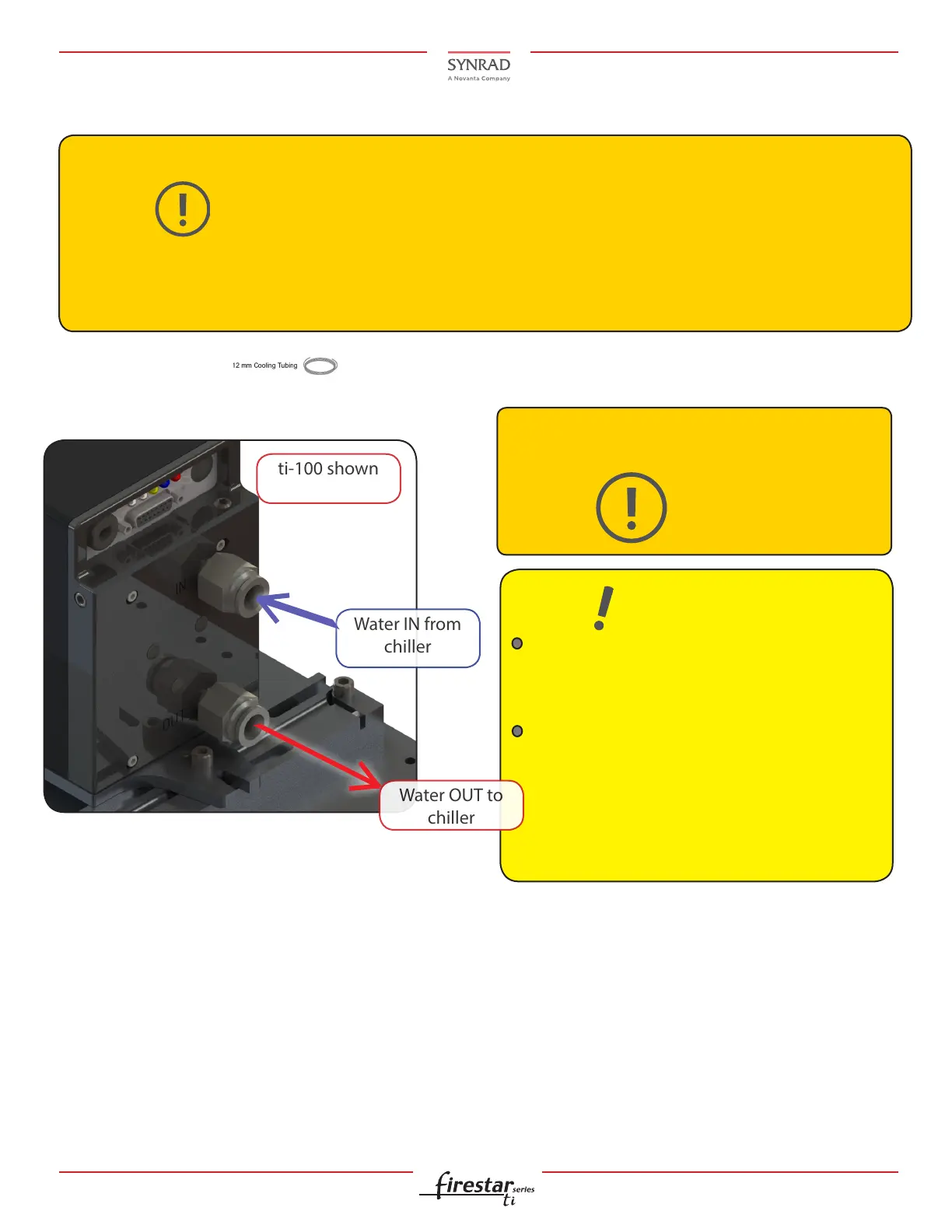

7. Set coolant temperature between 18–22 °C. See the Operation Manual for cooling specications, Main-

tenance/Troubleshooting and Technical Reference chapters for additional information on condensation

management.

Do not exceed coolant

pressure of 414 kPa (60

PSI)!

Assure coolant flow is within specifications

located in the Technical Reference chapter of the

Laser’s Operation Manual.

Refer to the dew point table and coolant flow

specifications in the aforementioned chapter in

the Operator’s Manual and gradually increase

coolant temperature until it is above the dew

point temperature and condensation disappears.

Do not exceed a coolant temperature of 30 °C (86

°F).

Important

Note:

If coolant ow needs adjusting:

Caution

Possible

Equipment

Damage

Loading...

Loading...