kitchens, in garages, near furnaces, hot water heaters, or gas space heaters.

• In very cold or very hot areas.

• In wet or excessively humid areas, or next to bathrooms with showers.

• In dusty, dirty, or insect-infested areas.

• Near fresh air inlets or returns or excessively drafty areas.

Air con-

ditioners, heaters, fans, and fresh air intakes and returns can drive

smoke away from the detector.

Note: This unit is UL listed as containing a supplemental sounder and should

not be used as a primary sounder for evacuation.

FIGURE 1: ALARM LOCATION DIAGRAM FOR RESIDENTIAL APPLICATION

LIVING

ROOM

BEDROOM BEDROOM

BEDROOM

KITCHEN

TO

BR

CLOSED

DOOR

BASEMENT

GARAGE

CARBON MONOXIDE/SMOKE ALARM

LOCATION FOR MULTI-LEVEL RESIDENCE

–

MOUNTING

The i

4

detector can be ceiling mounted or wall mounted:

1. To a single gang box, 2 in. by 4 in. box, 3½ in. or 4 in. octagonal or 3½

in. or 4 in. round ceiling

2. Direct mount to ceiling or to wall using drywall fasteners

FIGURE 2: MOUNTING OF DETECTOR

WIRING INSTALLATION GUIDELINES

All wiring must be installed in compliance with the NFPA 70 standards, Na-

tional Electrical Code, applicable state and local codes.

The screw terminals in the mounting base will accept 14-22 gauge wire.

Wire

connections are made by stripping approximately

3

/8" to ½" of insulation from

SS-500-003 2 I56-3747-001R

S0295-01

S0326-00

the end of the feed wire, inserting it into the proper base terminal, and tight-

ening the screw to secure the wire in place.

Do not put wires more than 2

gauge apart under the same clamping plate.

Remove power from alarm control unit or initiating device circuits before installing detectors.

1. Remove detector from packaging and separate the base from the detector head.

2. Wire the detector base screw terminals.

3. Screw the base of the detector onto an electrical box, or to the surface of

the wall or ceiling using the hardware included in the packaging.

4. Attach the detector head to the base by applying light pressure and rotat-

ing clockwise. The detector will lock in place when properly aligned.

5. After all detectors have been installed, apply power to the alarm control

unit. Refer to Table 3 for time to LED stabilization. Once stabilized, the

green LED will blink once every 5 seconds.

6. Test each detector as described in the Testing section.

7. Notify the proper authority that the system is in operation.

CAUTION

NFPA 72 recommends the installation of detectors only after completing construction or

any other dust producing activity

TABLE 2: LED INDICATION DURING POWER UP SEQUENCE

Green LED Red LED Blue LED

No Power OFF OFF OFF

Power on Reset Blink 5 Sec. Blink 5 Sec. Blink 5 Sec.

TABLE 3: POWER UP TIME TO FIRST ALARM / LED STABILIZATION

Power Up Time 45 Seconds

Power up time after

10 second reset

15 Seconds

LED Indication time

Typical: 45 seconds

Maximum: 55 seconds

Status LED indication

stabilization time

Typical: 55 seconds

Maximum: 268 seconds

TESTING

The detector must be tested after installation.

The detector has two discrete

test switches, one for smoke testing and one for CO testing.

The detector may

also be functionally tested using canned smoke and canned CO.

NOTE: Before testing, notify the proper authorities to avoid any nuisance alarms.

Ensure the proper wiring and power is applied to the detector.

After power

up, allow approximately 5 minutes for the detector to stabilize before testing.

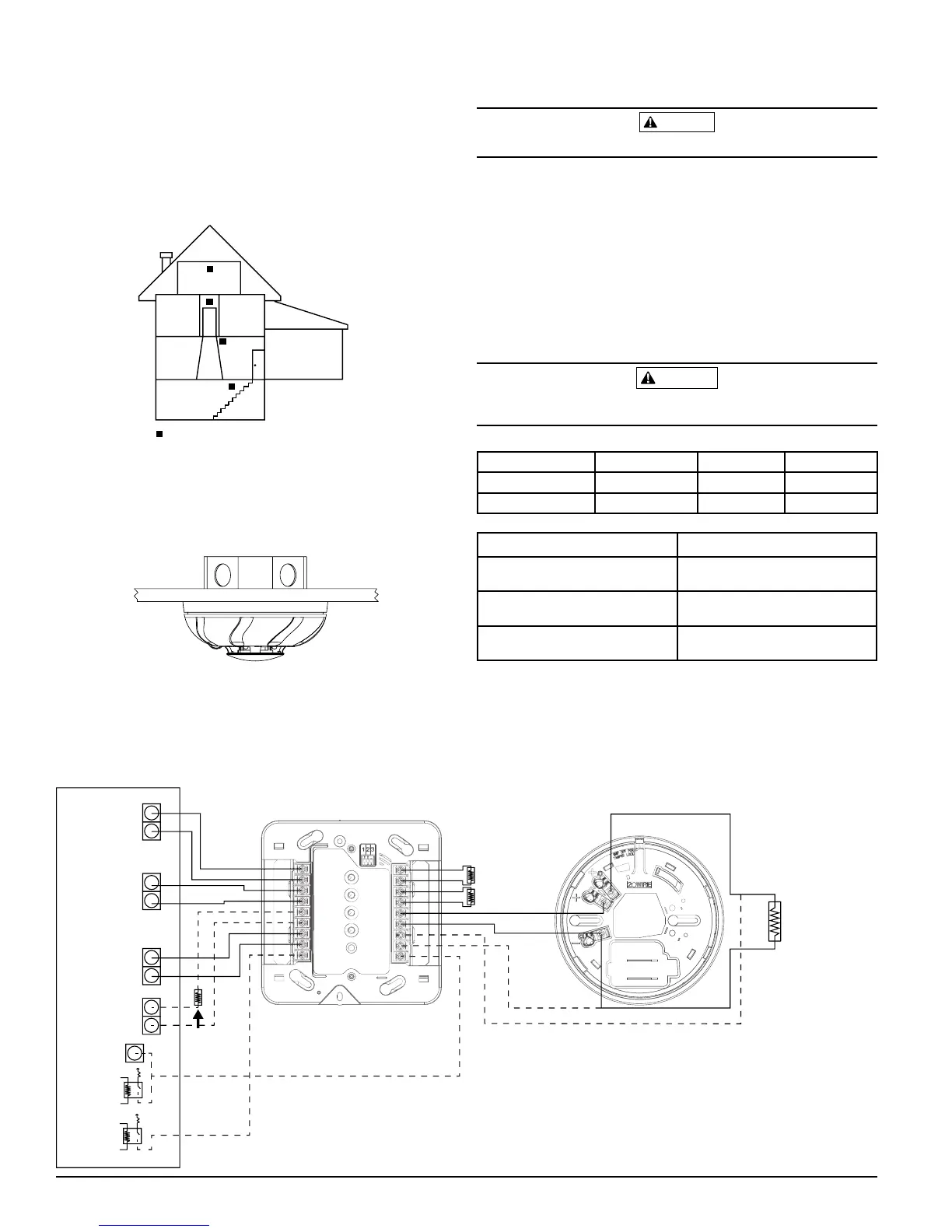

COSMO-2W

3.9k

RESISTOR

(supplied

with module)

LOOP STYLE D WIRING

SMOKE

AUXPOWER

(resettable)

SMOKE

ZONE

CO

ZONE

MAINT.

ZONE

SMOKE

TRIGGER OUT

Panel

EOL

Resistors

COSMOD2W

ALL CIRCUITS ARE SUPERVISED

(EXCEPT TRIGGERS) AND MUST

BE POWER LIMITED

Panel

EOL

Resistor

CO

TRIGGER

OUT

BELL

OR

S0329-00

FIGURE 3:

COSMO-2W WIRING DIAGRAM

Loading...

Loading...