DHR Series Getting Started Guide Page 37

Discovery Series Rheometer Geometries

Standard geometries for the rheometers are constructed from stainless steel, hard anodized aluminium, or

titanium.

NOTE: This applies only to the face of the geometry in direct contact with the sample, the shaft may be

constructed from other materials.

Other materials may be available on request, at additional charge. The geometry should be as low in den-

sity possible, to minimize its moment of inertia, it should be chemically resistant to the sample, and it

should have a surface texture that provides adhesion to the sample, to eliminate slippage.

The available geometries are listed below. Refer to TRIOS Online Help for additional details.

• Cone and plate

• Parallel plate

• Concentric cylinders

• Double gap concentric cylinders

• Solid sample (rectangular)

• SER2 Universal Testing Platform

• Interfacial

•Starch

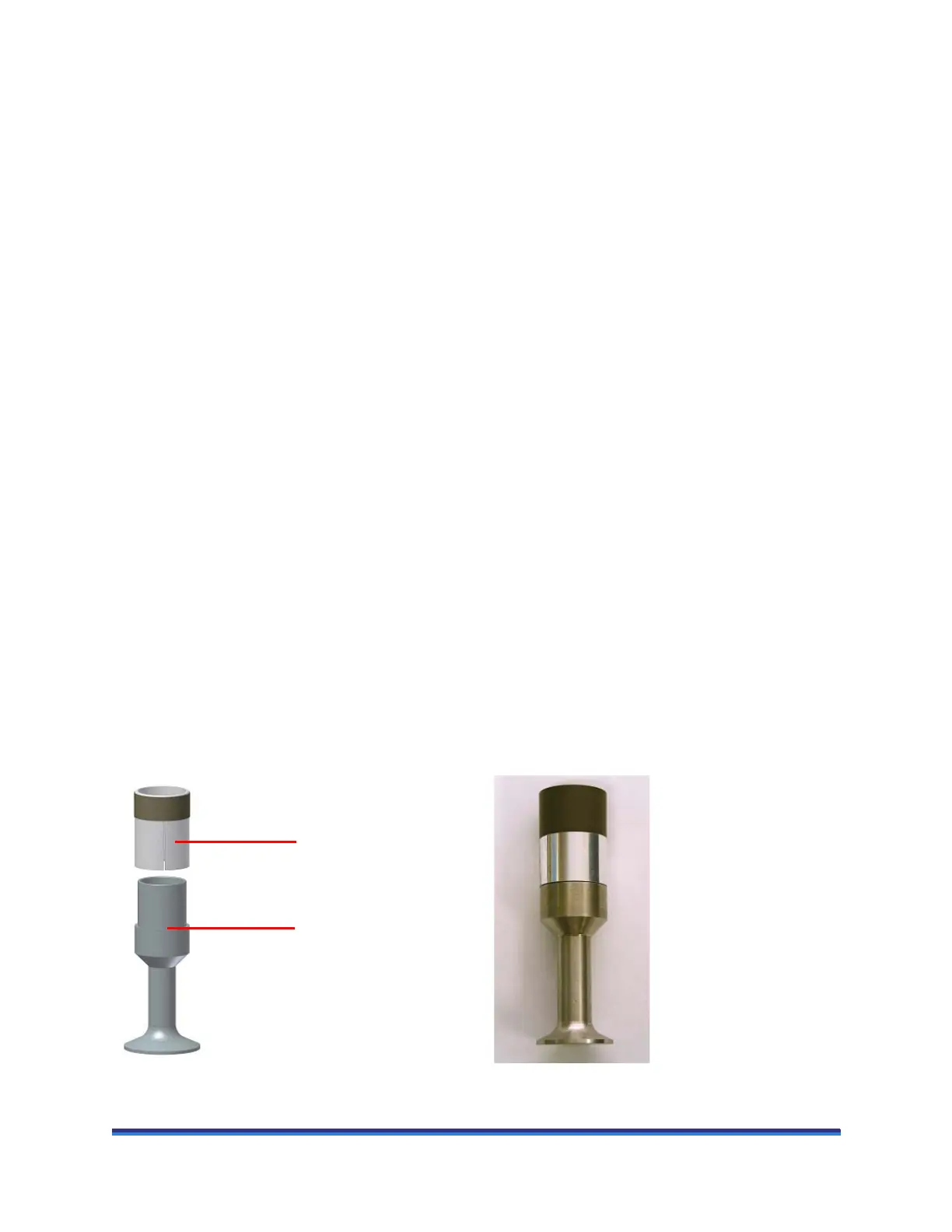

Smart Swap™ Geometries

Each geometry has a unique six-digit serial number for identification purposes. When the geometry is set

up for the first time this number is encoded into the magnetic strip and a link is established to a geometry

file in the instrument control software. The geometry then becomes “Smart”. When a Smart Swap Geome-

try is attached to the rheometer, a sensor registers the attachment and slowly spins the shaft to read the

serial number from the magnetic strip. The geometry file associated with this serial number is then loaded

by the software.

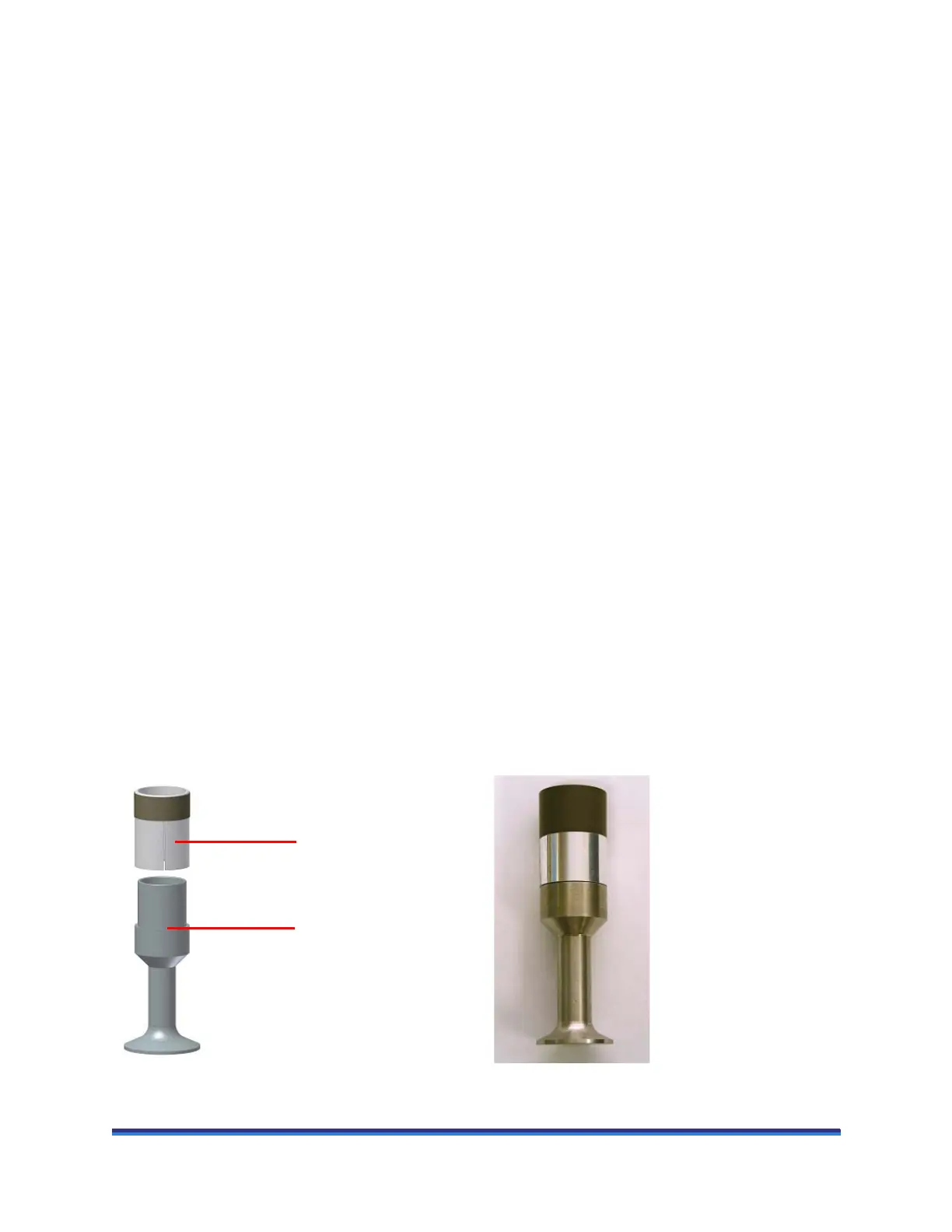

Figure 17 Smart Swap geometry.

Sleeve with

magnetic strip

Geometry base

Loading...

Loading...