-22-

14.3 Module Mode Selection

WARNING! Before performing any work on the module, make sure that the pump and module

electricity supply has been switched o and that it cannot be accidently switched on.

There is a mode selection rotary switch in the terminal box. It can be rotated by gently inserting a screwdriver

into the arrow mark on top and rotating the switch to desired value.

IMPORTANT: Cycle the pump power supply o for 20 seconds after a mode change.

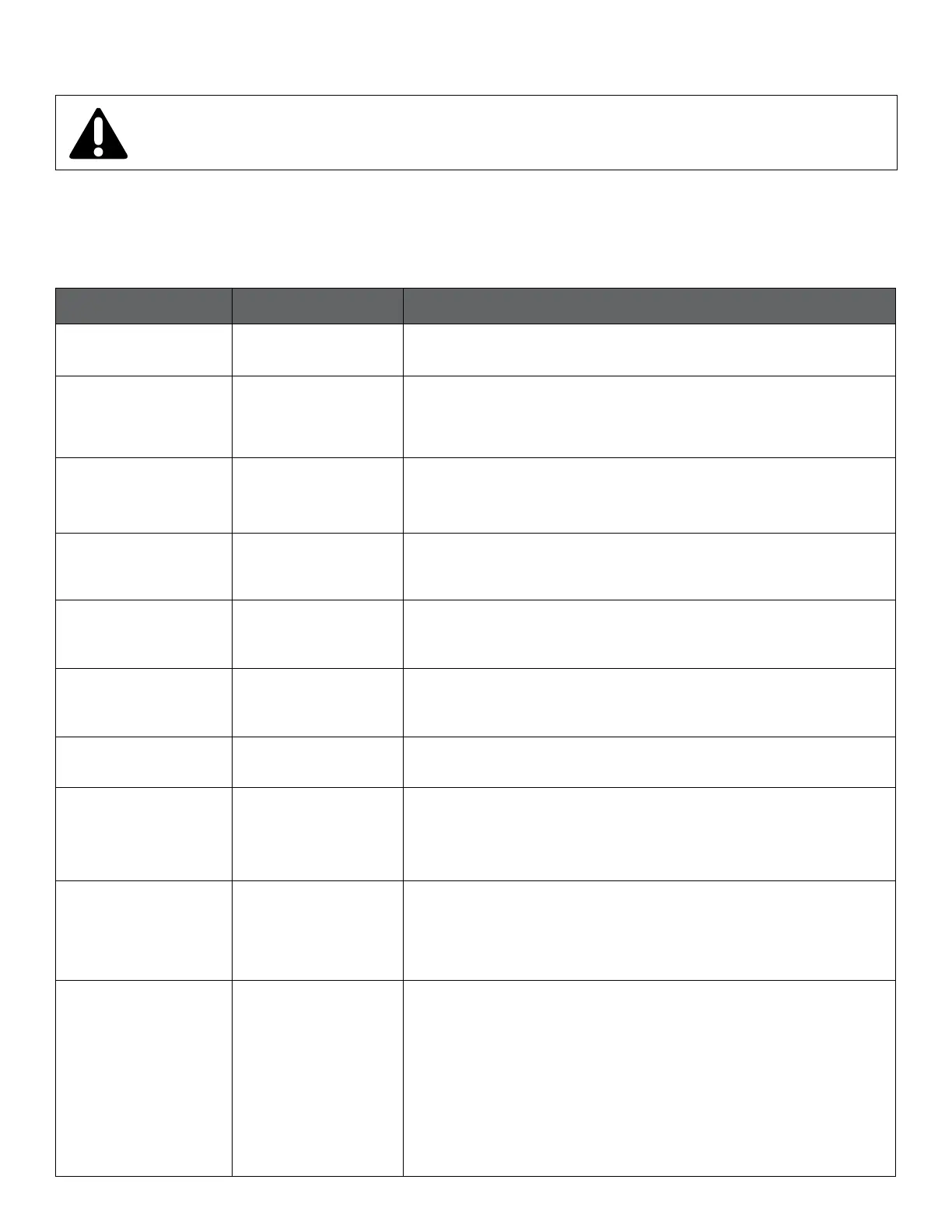

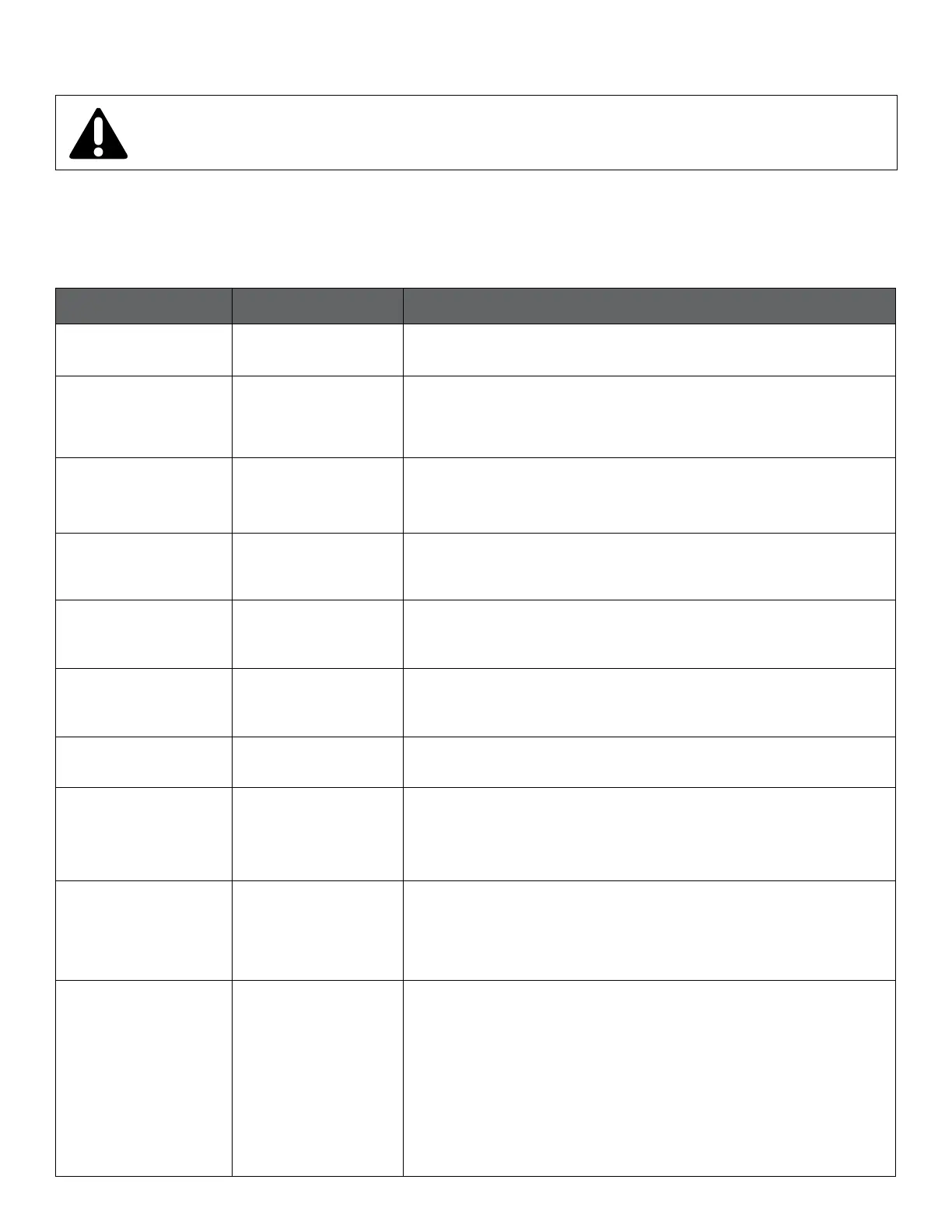

Mode Switch Position Function Description

0 Free conguration Terminal functions are congured over Ethernet interface.

1

Mode 1 Factory

Default

(2-10Vdc control)

SET1 = RUN input

SET2 = MAX input

SET3 = FB (10.5 V) output, used to supply RUN and MAX inputs

See Section 14.4 “Mode 1”

2

Mode 2

(0-10Vdc control)

SET1 = RUN input

SET2 = SPEED input

SET3 = FB (10.5 V) output, used to supply RUN and MAX inputs

See section 14.5 “Mode 2”

3

Mode 3

(PWM Solar)

SET1 = PWM-in (0 % = Pump OFF)

SET2 = PWM-out status

SET3 = FB (10.5 V) output, can be used to supply SET1 and SET2

4

Mode 4

(PWM Heating)

SET1 = PWM-in (100 % = Pump OFF)

SET2 = PWM-out status

SET3 = FB (10.5 V) output, can be used to supply SET1 and SET2

5 RESERVED Reserved for future or customer specic use.

6

Show relay

conguration

LED1 and LED2 will show relay conguration. See section “5 Relay output”.

7

Change relay

conguration

Relay conguration will be increased (0->1, 1->2, 2->0) when power is

turned on.

LED1 and LED2 will show current relay conguration.

See section “5 Relay output”.

8 Twin reset to factory

Same as Mode 9, with exception of:

module IP address is set to 192.168.0.246

Twin IP address is set to 192.168.0.245

9 Reset to factory

This mode will set communication interface to default values.

Main purpose is to restore default settings.

NOTE:

• Disconnect any SET1, SET1, SET2, SET3 will output test voltages of 10 V, 7 V

and 5 V respectively. RS-485 port is actively driven. Relay will cycle.

• It is recommended that all module wires are disconnected to prevent

possible harm to external controllers

Loading...

Loading...