15

WARNING: Read the Operating Procedure

completely before operating your tile saw.

Take into account the working conditions from

the health and safety point of view.

Always pay extreme care and attention to the

preparation of the machine before starting.

Remove all wrenches and tools from the

machine.

Always keeps blade guard in place.

Fill the Pan (3) with enough water to fully submerge the

water pump screen. It takes approximately 6-1/2

gallons (25 l) to fill the Pan.

Before connecting the power cord:

* Check the Blade Shaft Nut (L) to be sure it is tight

and that the Blade (K) rotates freely.

WARNING: Check that the ON/OFF switch is in

the OFF position. Then connect the power cord

to a properly grounded outlet of the

correct voltage. See the decal near the power

cord for power requirements. If needed, use the

correct size three (3) conductor extension cord

to avoid excessive voltage drop. Never use lamp

cord type extensions. Refer to the

Recommended Extension Cords chart below.

Turn the switch to ON. The blade should turn

counter-clockwise, when looking at the blade guard

side. The water pump will start automatically when the

motor starts. Adjustment of the water supply may be

made by means of the Control Valve(G).

6. Lower the Blade Guard (J) and retighten the wing

nut to securely hold the guard in place.

Install the Drain Plug (P) into the front end of the pan

and fill with clean water until inlet filter of water pump is

covered; about 6.5 gal. (25 l).

Adjust the Pan Assembly (3) to accommodate the size

of the tile to be cut and to obtain the most comfortable

position for the operator.

1. When cutting smaller tile units, adjust the pan all

the way to the rear. The operator has full view and

control of the work with minimum stretching.

2. For cutting intermediate sized units, such as 8" or

10" tile, the pan can be placed somewhere between

the maximum forward and maximum rear positions.

3. When cutting

larger units, the pan should be moved

to the maximum forward position, thus giving the

operator the best and most comfortrable position,

even when cutting 12" x 12" or larger units.

Follow the blade manufacturers recommendations for

dry or wet cutting. Wet cutting blades can be damaged

or destroyed without sufficient water. Only blades

specifically designed for dry cutting can be used with-

out coolant.

The water supply should be adequate, with

water flowing on both sides of the blade. Keep

the water clean and make certain the WATER

LEVER IS ALWAYS ABOVE THE PUMP INLET.

Do not run the water pump dry!! Unplug for dry

cutting.

For straight cuts, position the tile squarely against the

back edge of the conveyor cart. Keep the cart clean

and free of cuttings. The standard Rip Guide (R) is used.

Move the conveyor cart slowly and carefully until the

blade is in contact with the tile. The blade needs a

chance to break-in or wear-in slightly. It may take

about ten cuts to open a new blade for best cutting.

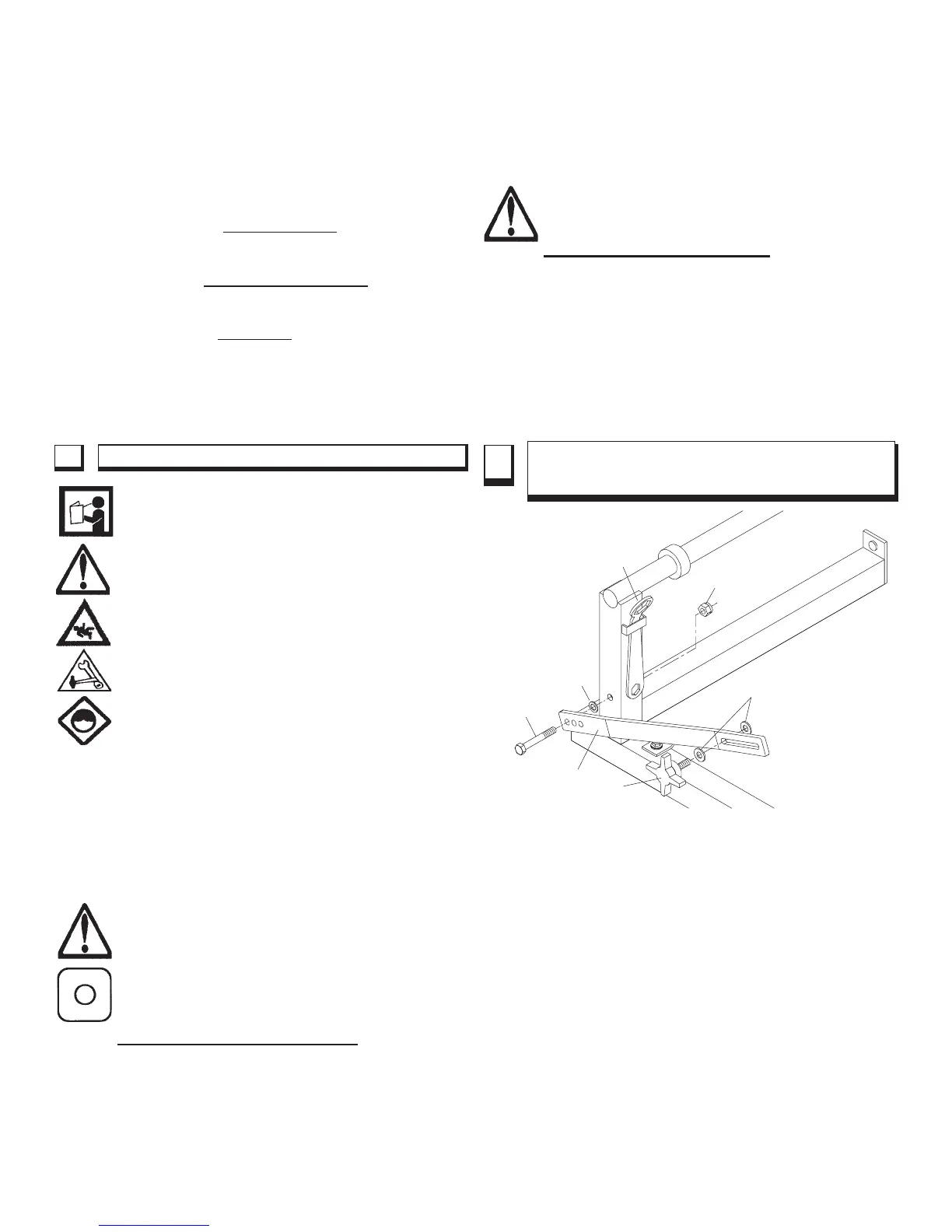

4 OPERATING PROCEDURE

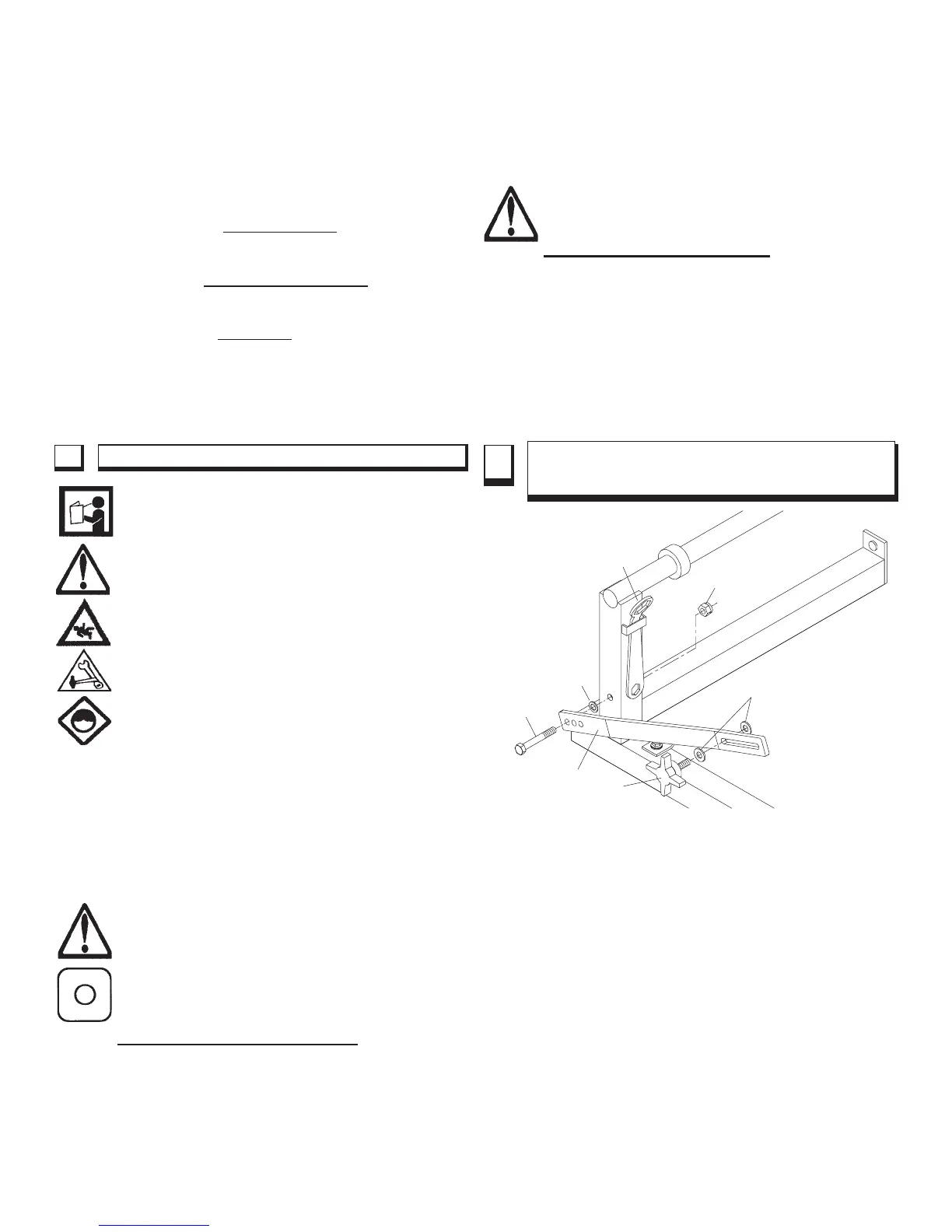

5 ADJUSTABLE LOCKBAR WITH DEPTH

LINKING PROTECTION

A Lockbar (28) is used to set the blade depth during

cutting. The lockbar has three (3) holes at the lower end

marked 10, 8 and 6.

These are used as depth-limiting settings that, if used with

the correct blade diameter, will protect the rolling cart from

being cut by the blade.

The three (3) holes in Lockbar:

10 - The lowest hole is for use with a 10" diameter

blade.

8 - The middle hole is for use with an 8" diameter

blade.

6 - The uppermost hole is for use with a 6" diameter

blade or profile wheel.

The Tilematic is shipped standard set-up for a

10" diameter blade. To change the setting, locate the

capscrew (23) used as the pivot, loosen and remove the

Lock Nut (25). Set the Lockbar ( 28) at the proper hole.

Tighten the fasteners so that the Lockbar (28) is free to

23

28

26

27

24

25

29

FIGURE 2

Loading...

Loading...