17

Before performing any maintenance, ALWAYS

place the machine on a level surface with the

motor OFF and disconnect the electrical current.

Let the machine cool down!!

Your TARGET® tile saw is a ruggedly constructed machine,

engineered to give long, satisfactory performance. Simple

daily maintenance and care will add to the life and

productivity of your saw. After each days use: CLEAN THE

MACHINE!!

* Turn off and unplug the saw before performing any

maintenance.

* Keep the cart top clean and free for cuttings. To

clean it, flush the top surface and grooves with

water.

* Drain, clean and refill the pan frequently. Flush the

coolant system with plenty of water, then drain and

refill the pan.

* If the water flow stops, check the water pump to

see if the shaft and impeller turn freely. See the

WATER PUMP TROUBLE-SHOOTING

PROCEDURE section.

* It is always good practice to clean your tile saw

after each days use. Drain the water and clean

out the pan. Clean the rails. Before storing, it is

good practice to wipe or spray rails with water-

soluble oil (like, WD-40 or equivalent).

Entrust all repairs to your authorized dealer only.

Locate the material for profiling:

1. Set the edge of the part to be shaped parallel to

the wheel.

2. Locate the material under the wheel. Pull the

Conveyor Cart (4) with the material from under the

wheel to set proper cutting height.

3. Loosen the Locking Knob (C) and lower the Cut-

ting Head (1) so that the wheel just slightly makes

contact with the material.

4. Secure the Cutting Head (1) into position with the

Locking Knob (C) for cutting.

5. Note: Profiling usually takes several light passes

to produce the best results. Set lower each time

until the desire depth has been reached.

10 MAINTENANCE PROCEDURES

11 WATER PUMP TROUBLE-SHOOTING PROCEDURE

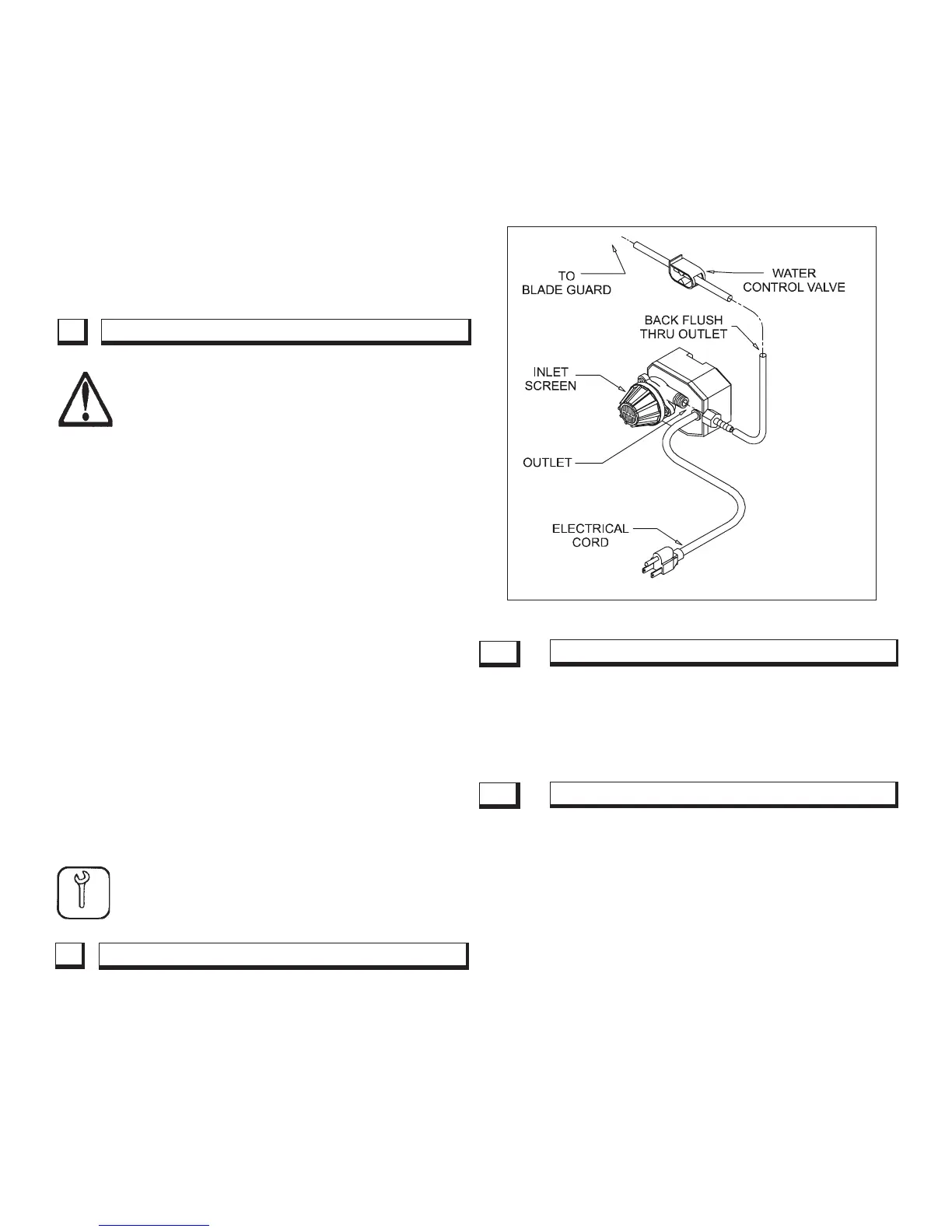

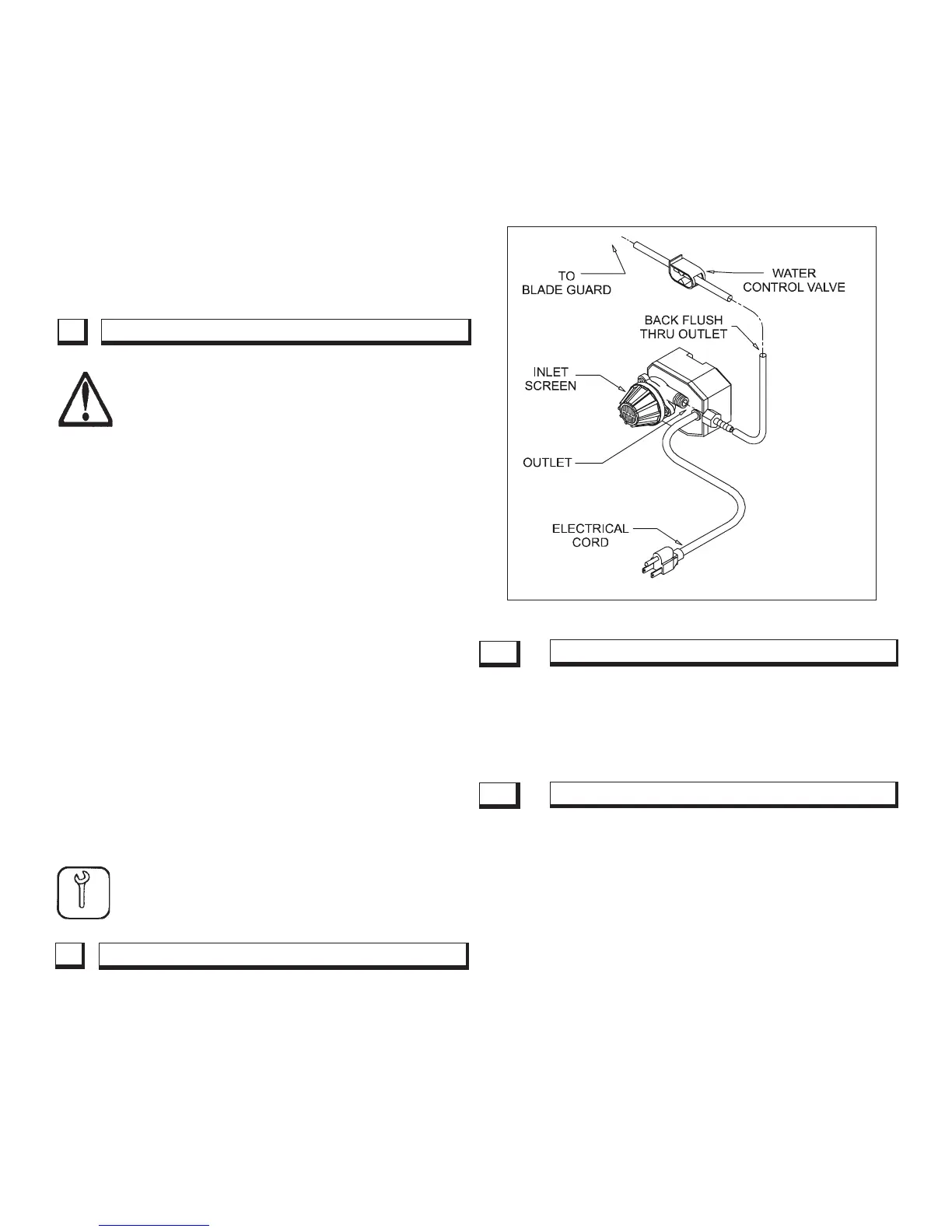

Back flushing is done by forcing water into the pump discharge

and out through the screen. Most of the time this procedure

works, and the pump can be put back into service. (See

Figure below)

If the back flushing does not work, remove the screen and

turn the impeller manually, looking for and rinsing out the im-

peller cavity of any dirt or foreign matter.

If Water Stops Flowing,

1. Stop Sawing, then

2. Disconnect Electrical Plug from Outlet, then

3. Remove the Pump, then

4. Back Flush.

For quick supply of spare parts and to avoid any lost time, it is

essential to quote the data on the manufacturers plate fixed to

the machine and the part number(s) and description to be

replaced with every order.

12 REPAIRS

13 SPARE PARTS

We carry out all repairs in the shortest possible time and at

the most economical prices. (See front page for

address and phone numbers) Contact your authorized

TARGET® dealer concerning maintenance and repairs.

FIGURE 4

Loading...

Loading...