3

Models 702/741/772 To the Installer

110616

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected, not used for long

periods, or during initial installation, shall

have protective devices such as a GFI to

protect against the leakage of current and

be installed by authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed, flexible cable, not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting at the terminals, and

protect the insulation of the conductors from

abrasion.

Check Out

Once the unit is installed, it is advisable to check the

following controls and mechanical operations of the

freezer and make any necessary adjustments. If

applicable, repeat these checks for the second

freezing cylinder on double head units.

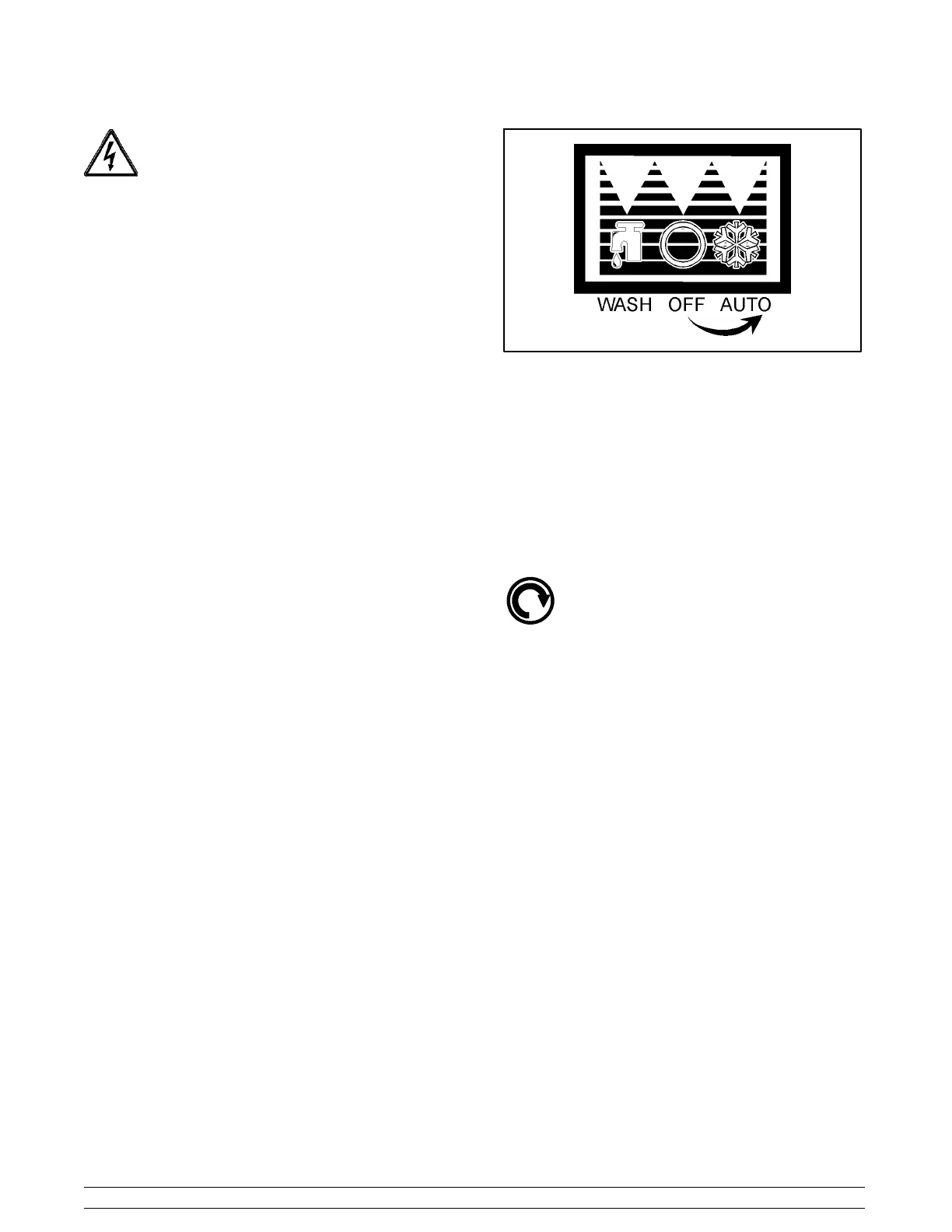

Controls

Place the control switch in the “AUTO” position. The

main refrigeration system will operate (compressor,

beater motor, and the condenser fan). The dial light

and the mix low indicator will be lit.

Figure 1

If the freezer is water cooled, the automatic water

valve will begin to open and cold water will flow into the

condenser. This will remove heat from the refrigerant.

As the water flows into the open trap drain, it should be

warm to the touch. Place the control switch in the

“OFF” position.

Beater Rotation

Beater rotation must be clockwise as viewed

looking into the freezing cylinder.

Note: The following procedures must be

performed by an authorized Taylor service

technician.

To correct rotation on a three-phase unit, interchange

any two incoming power supply lines at the freezer

main terminal block only.

To correct rotation on a single-phase unit, exchange

leads inside the beater motor. (Follow the diagram

printedonthemotor.)

Electrical connections are made directly to the

terminal block provided in the main control box located

behind the upper left side panel for the Model 702, and

behind the service panel for the Model 741 and 772.

Loading...

Loading...