Section 6

6-1

Models 750, 751, 754, 774, 791, and 794

Operating Procedures

6

Operating Procedures

Model 751 has been selected to illustrate the

step-by-step operating procedures for all models

contained in this manual. These models, for all practical

purposes of operation, are the same.

Each machine stores mix in a hopper. The mix then flows

by gravity through an air tube down into the freezing

cylinder. They all have 3.4 qt. (3.2 L) capacity freezing

cylinders. Models 750, 751, 754, and 774 have 20 qt.

(18.9 L) mix hoppers. Models 791 and 794 have 14 qt.

(13.2 L) mix hoppers.

Duplicate the following procedures where they apply for

the second freezing cylinder on Models 754, 774, 791,

and 794.

We begin our instructions at the point when we enter the

store in the morning and find the parts disassembled and

laid out to air-dry from the previous night's cleaning.

These opening procedures will show you how to

assemble these parts into the freezer, sanitize them, and

prime the freezer with fresh mix in preparation to serve

your first portion.

If you are disassembling the machine for the first time or

need information to get to this starting point in our

instructions, turn to

page 6-9, “Disassembly,” and start

there.

Prior to Setup (Model 774)

1. Remove the two stainless-steel syrup jars with

topping pumps from the syrup rail. Check the water

level in the heated syrup topping well. Make sure the

water is filled to the indicating mark on the bottom of

the well. The heated rail should have 32 oz.

(946.2 ml) of water.

2. Place the heater switch in the ON position.

Note: This heating process will take approximately

2.5 hours to reach temperature. The water level in

the topping wells must be checked at least once

daily.

3. Prepare a pail of an approved 100 ppm sanitizing

solution (examples: 2.5 gal. [9.5 L] of Kay-5

®

or 2 gal.

[7.6 L] of Stera-Sheen

®

).

Use warm water and follow the manufacturer's

specifications. Sanitize the topping pumps by

placing the entire pump assembly in the pail of

sanitizing solution. Pump the solution through the

assembly to thoroughly sanitize the pump.

4. Remove the two topping pumps. Fill each stainless

steel syrup jar with topping. Replace the topping

pumps in the syrup jars.

Assembly

Note: When lubricating parts, use an approved

food-grade lubricant (example: Taylor Lube).

WARNING! Make sure the power switch is in

the OFF position! Failure to follow this instruction may

result in severe personal injury to fingers or hands from

hazardous moving parts.

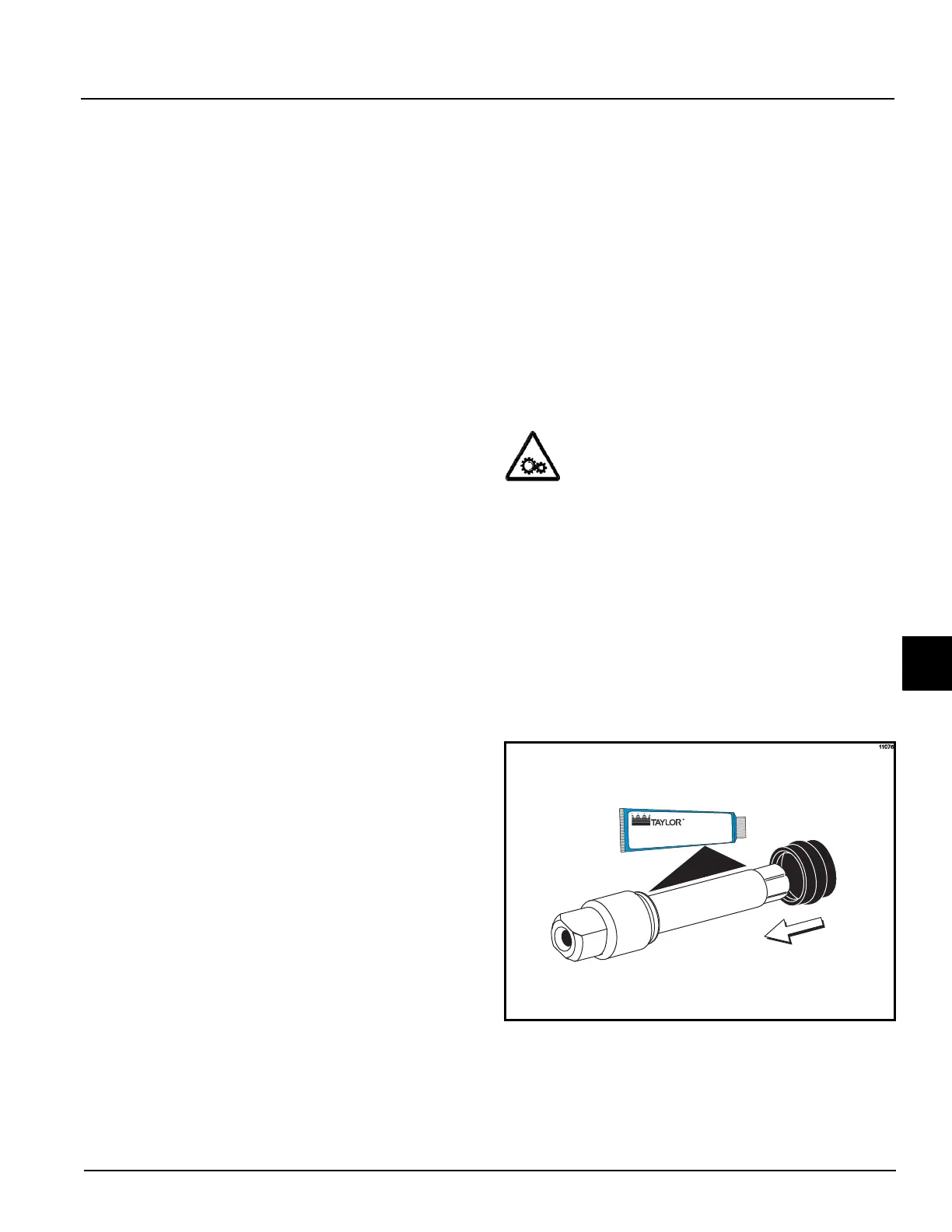

1. Lubricate the groove and shaft portion that comes in

contact with the bearing on the beater driveshaft.

Slide the seal over the shaft and groove until it snaps

into place. Do not lubricate the hex end of the

driveshaft. Fill the inside portion of the seal with

1/4 in. (6.35 mm) more lubricant and lubricate the flat

side of the seal that fits onto the rear shell bearing.

Figure 6-1

Apply the appropriate

Taylor approved food safe lubricant.

Loading...

Loading...