1-31-3THDC / THDCP - 954 / 955 / 974 (Rev. 06/03)THDC / THDCP - 954 / 955 / 974 (Rev. 06/03)

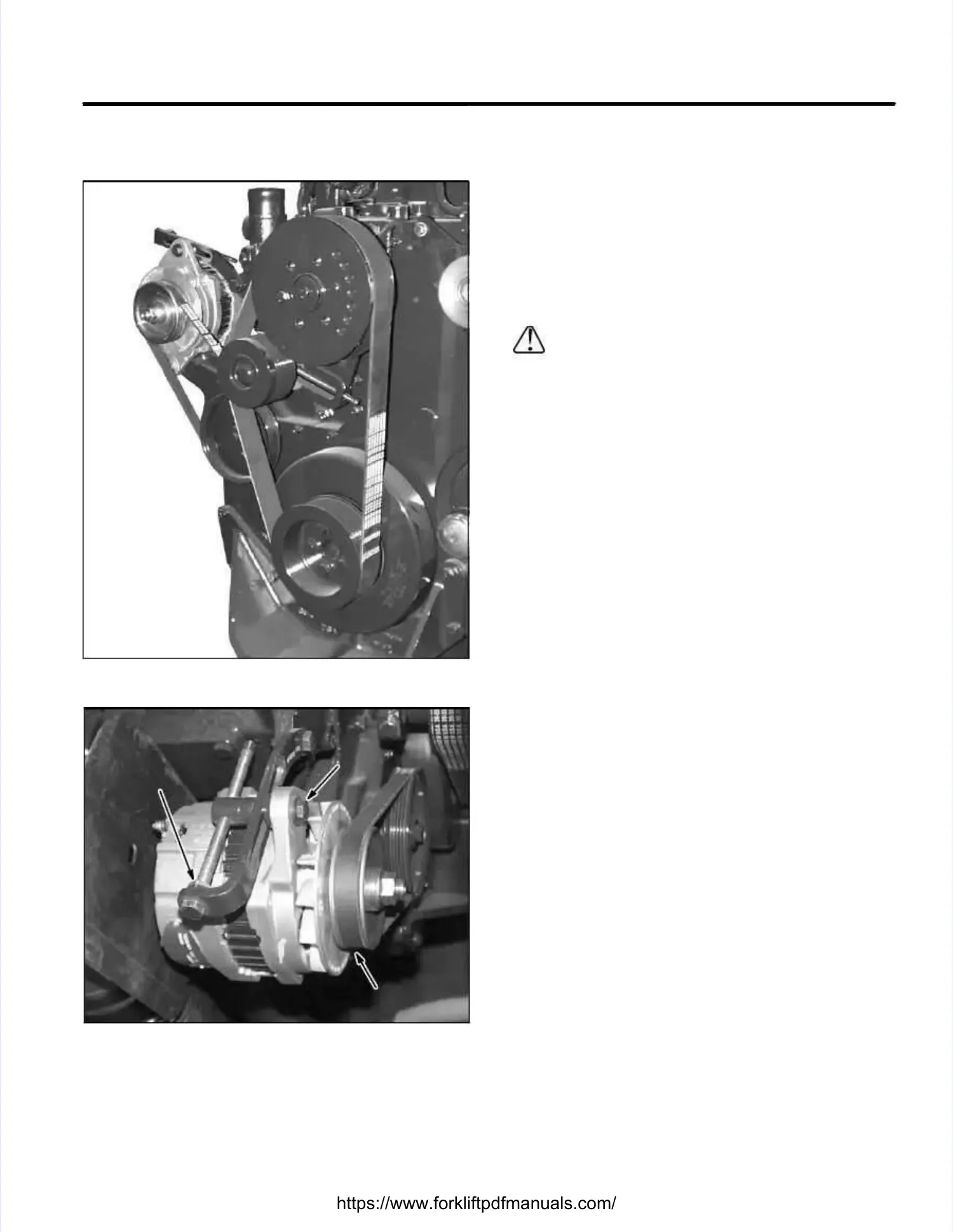

IllustIllustration 1-ration 1-3. 3. Fan DriFan Drive Beltve Belt

ADJUSTING

ADJUSTING

SCREW LOCKNUTSCREW LOCKNUT

ADJUSTMENTADJUSTMENT

LINK LOCKINGLINK LOCKING

CAPSCREWCAPSCREW

PIVOT CAPSCREWPIVOT CAPSCREW

AND NUTAND NUT

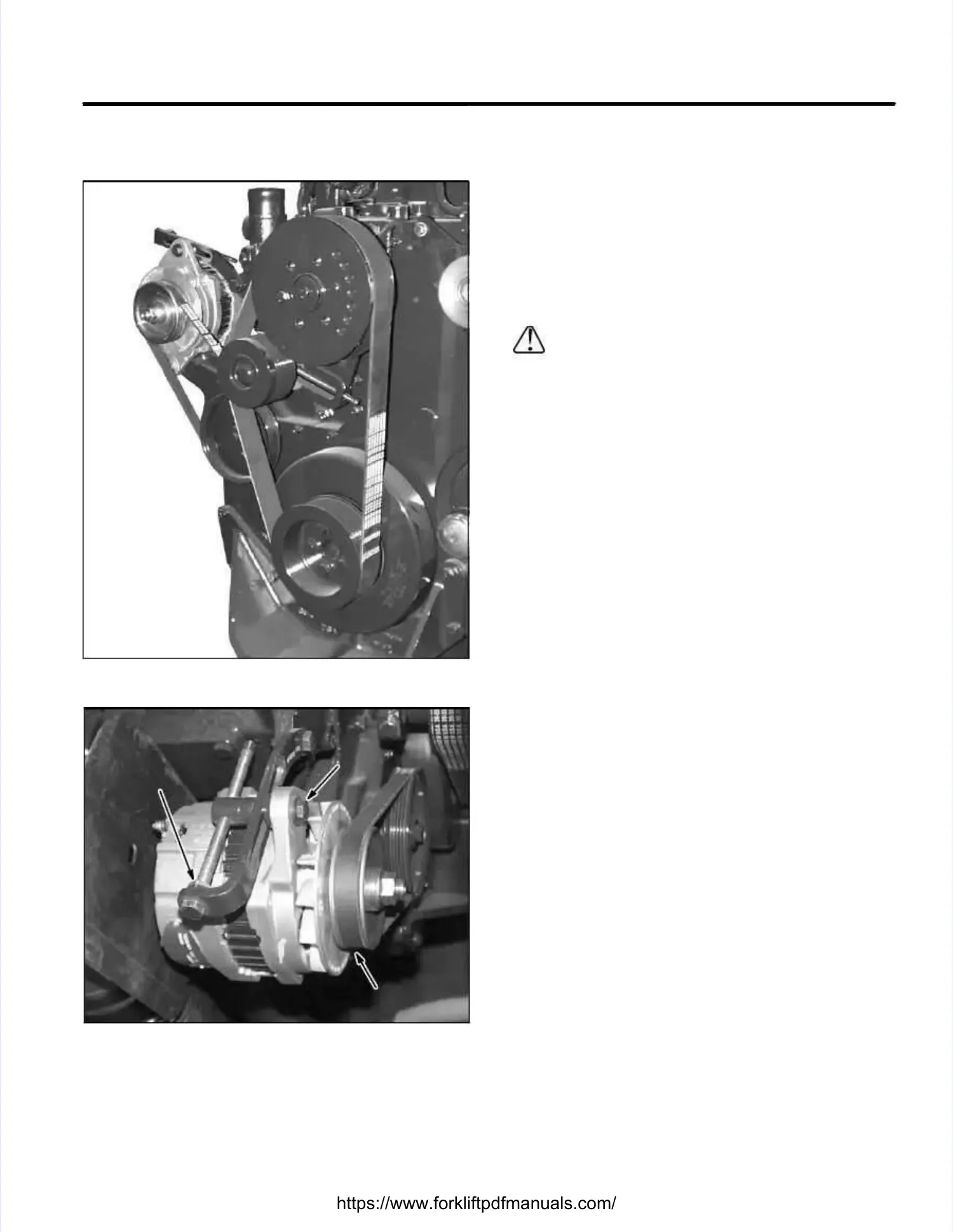

IllustrIllustration 1-4. ation 1-4. Alternator DAlternator Drive Beltrive Belt

Fan Drive Belt TensionFan Drive Belt Tension(Illustration 1-3)(Illustration 1-3).. TheThe

tension of the fan drive belt should be 200 - 240tension of the fan drive belt should be 200 - 240

ft-lbs (890 - 1070 Nft-lbs (890 - 1070 N

⋅⋅

m) for a used belt and 300m) for a used belt and 300

ft-lbs (1330 Nft-lbs (1330 N

⋅⋅

m) for a new belt. A belt is consid-m) for a new belt. A belt is consid-

ered used if it has been in operation for 10 min-ered used if it has been in operation for 10 min-

utes or longerutes or longer. . If the used belt tensiIf the used belt tension is less thanon is less than

the minimum tension value, tighten the belt to thethe minimum tension value, tighten the belt to the

maximmaximum tension value. um tension value. TTo obtain the proper belto obtain the proper belt

tension value, use an appropriate belt tensiontension value, use an appropriate belt tension

gauge. gauge. Perform Perform the followthe following proceduring procedures toes to

adjust the tension of the belt.adjust the tension of the belt.

CAUTION:CAUTION:Do not adjust belt tension toDo not adjust belt tension to

the maximum value with the adjusting screw.the maximum value with the adjusting screw.

Belt tension can increase when the locknut isBelt tension can increase when the locknut is

tightened and cause reduced belt and bearingtightened and cause reduced belt and bearing

life.life.

1. 1. LoosLoosen the idleen the idler pullr pulley shafey shaft lockt locknut.nut.

2. 2. AdjuAdjust the belst the belt to the cort to the correcrect tensit tension by turnon by turninging

the adjusting screw clockwise until the properthe adjusting screw clockwise until the proper

belt tension is obtained (seebelt tension is obtained (seeCautionCautionabove).above).

3. 3. TTightighten the idlen the idler puller pulley shafey shaft lockt locknut to anut to a

torque value of 140 ft-lbs (190 Ntorque value of 140 ft-lbs (190 N

⋅⋅

m).m).

4. 4. ChecCheck the belt tk the belt tensiension again to mon again to make surake sure thee the

belt is adjusted to the correct value.belt is adjusted to the correct value.

Alternator Drive Belt TensionAlternator Drive Belt Tension(Illustration 1-4)(Illustration 1-4)..

The tension of the alternator drive belt should beThe tension of the alternator drive belt should be

60 - 120 ft-lbs (270 - 530 N60 - 120 ft-lbs (270 - 530 N

⋅⋅

m) for a used belt andm) for a used belt and

150 ft-lbs (670 N150 ft-lbs (670 N

⋅⋅

m) for a new bem) for a new belt. lt. A belt is cA belt is con-on-

sidered used if it has been in operation for 10 min-sidered used if it has been in operation for 10 min-

utes or longerutes or longer. . If the used belt tensiIf the used belt tension is less thanon is less than

the minimum tension value, tighten the belt to thethe minimum tension value, tighten the belt to the

maximmaximum tension value. um tension value. TTo obtain the proper belto obtain the proper belt

tension value, use an appropriate belt tensiontension value, use an appropriate belt tension

gauge. gauge. Perform Perform the followthe following proceduring procedures toes to

adjust the tension of the belt:adjust the tension of the belt:

1. 1. LoosLoosen the adjen the adjustiusting scrng screw locew locknutknut..

2. 2. Loosen the adjLoosen the adjustment ustment link llink locking cocking capscrewapscrew..

3. 3. LoosLoosen the pien the pivot cvot capscapscrew rew and nutand nut..

4. 4. AdjusAdjust the belt to tht the belt to the corre correct teect tensionsion by turnin by turningng

the adjusting screw clockwise until the properthe adjusting screw clockwise until the proper

belt tension is obtained.belt tension is obtained.

5. 5. TiTighten the ghten the adjusting adjusting screw screw locknut locknut againstagainst

the retainer.the retainer.

6. 6. TiTighten the adjghten the adjustment ustment link llink locking cocking capscrewapscrew

to a to a torqtorque value of 60 ue value of 60 ft-ft-lbs (80 Nlbs (80 N

⋅⋅

m).m).

7. 7. TTightighten the piven the pivot capsot capscrew acrew and nut to a torqund nut to a torquee

value of 35 ft-lbs (47 Nvalue of 35 ft-lbs (47 N

⋅⋅

m).m).

Engine Cleaning.Engine Cleaning. The engine must be steamThe engine must be steam

cleaned every 6 months or 1500 hours, whichevercleaned every 6 months or 1500 hours, whichever

Loading...

Loading...