KMS-2/Exia Transmitter

Installation and Operating Manual

ATEX

Page 12 of 13

KMS-2/Exia IOM Rev C 14/06/2018

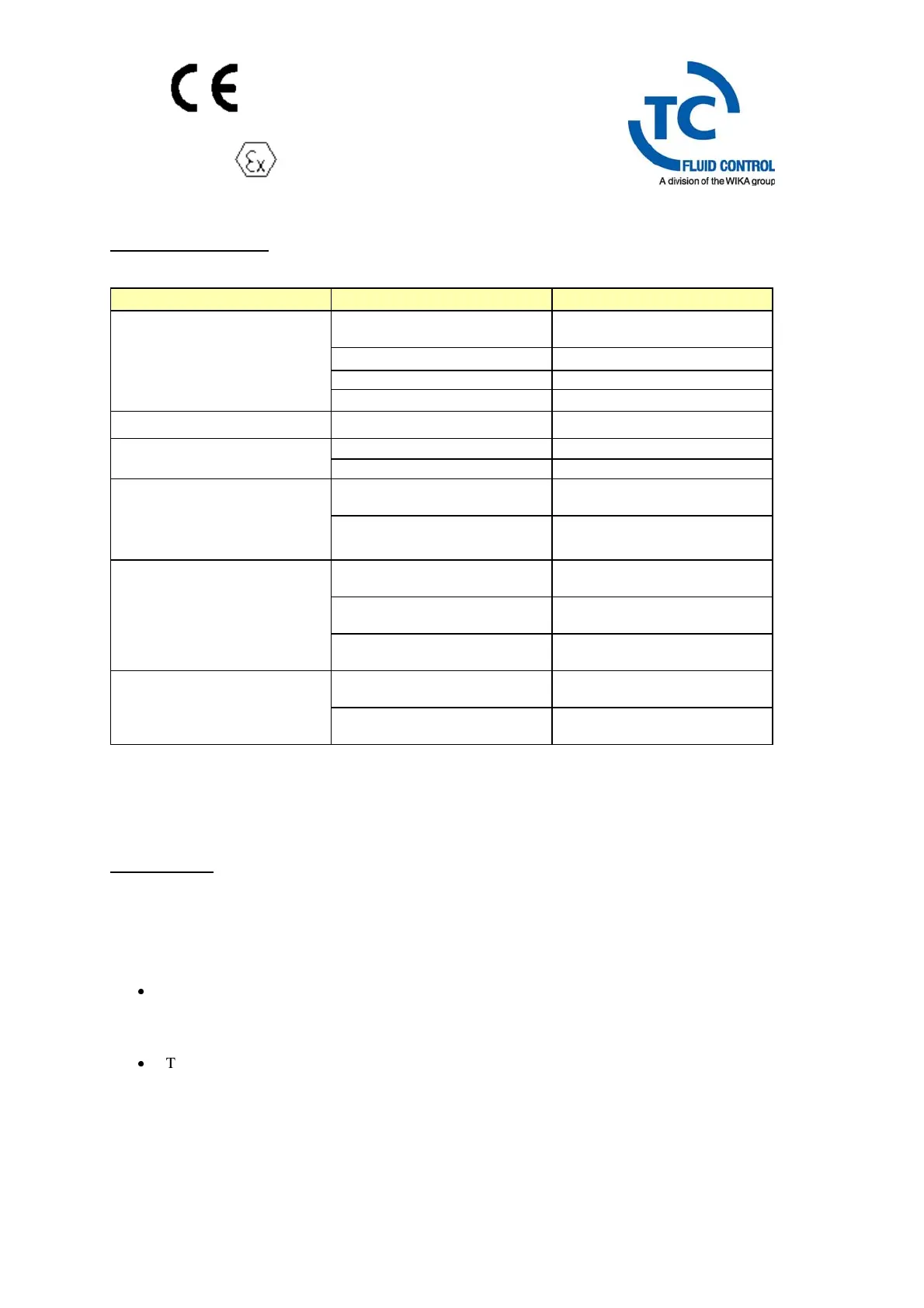

Fault analysis Sheet

Problem Possible Fault Action

Zero current eg. 0mA

Supply Voltage to low < 8V Check voltage and adjust

accordingly

Supply Connections reversed Swap supply cables

Cables/Connecting circuit faulty Rectify as required

Faulty Unit Consult Factory.

Current Greater than 22mA Supply voltage to high > 28V Adjust voltage to less than 28V

Output at

3.8mA (Low level)

Float damaged (sunk) Fit new float

Chamber empty Open check valves

Continual reading of either

3.58mA Downscale

22mA Upscale

Float magnetic field not being

sensed

Check gap distance between

chamber and transmitter

Float Under magnetised

Check with spare float if

available

Output static at a particular level

Float stuck or damaged

Check against visual display if

fitted. Check float condition

Residual magnetic interference

Run magnet along full length of

probe, Consult Factory.

External magnetic interference

Check for external magnetic

devices in vicinity.

4-20mA not proportional to

liquid level

“XXXX” marks not in line with

vessel connections

Realign transmitter marks

correctly

S.G range of float incorrect for

media type

Check S.G etched on float

against media S.G

Table 3

Fault Analysis

Maintenance

The unit contains no user serviceable parts; therefore no routine maintenance is required.

Dependent on model or application:

For coated options:

•

Where the case of the device may be subjected to impact or friction, periodic examination is

required to ensure that the integrity of the stove enamelled finish is maintained.

For Immersion Applications

•

The sensor tube must be kept clean to prevent the float “sticking”.

Loading...

Loading...