The electrode tip can have two different shapes according to the

work to be carried out:

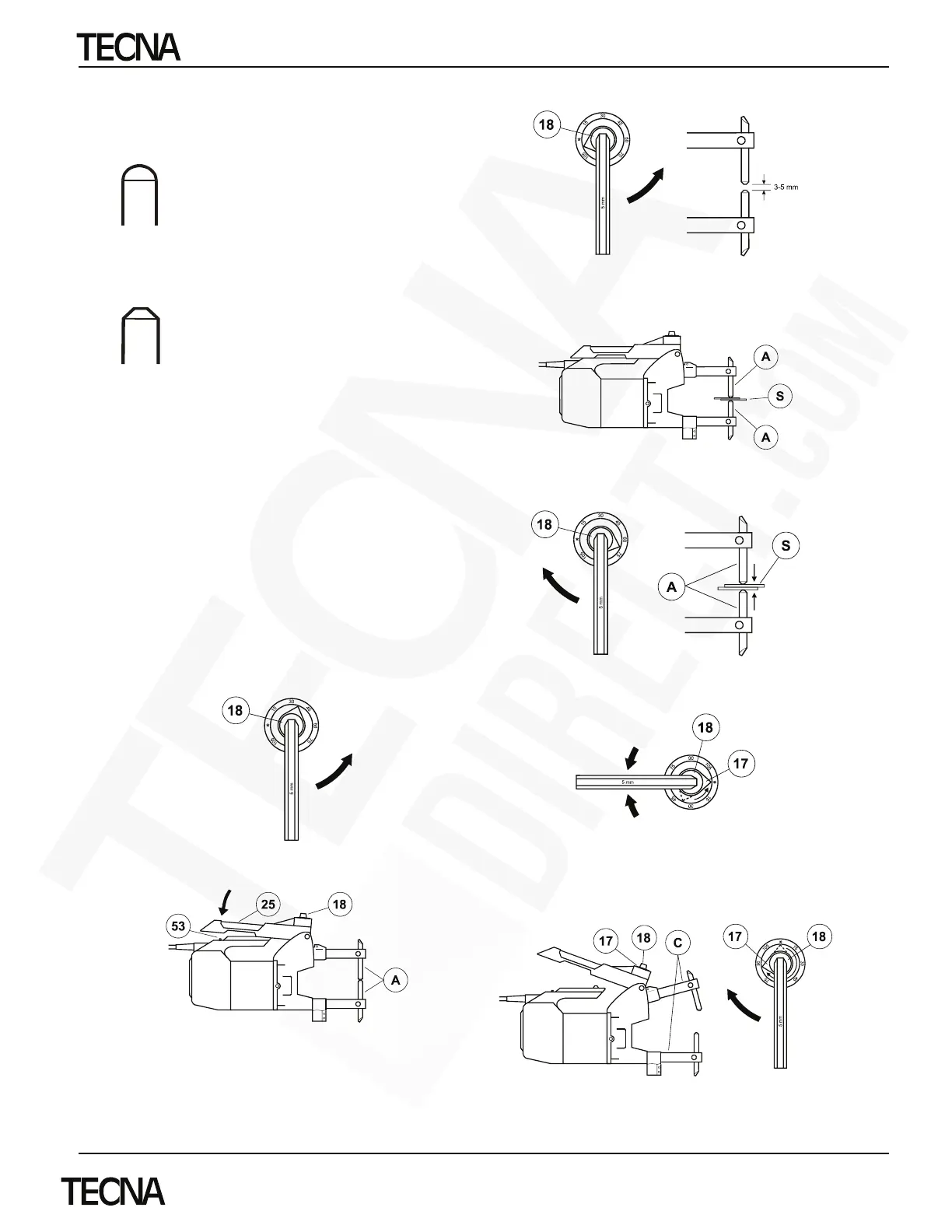

DOME TIP

With this shape, it is not necessary to match the

electrodes to the piece to be welded and maintenance

is easier and quicker. The sharpener supplied as

standard (range 7900-7902 only) will quickly restore to

good condition the electrodes. The sharpener should

be used on a drill at a speed of 300-600 rpm.

The dome tip electrodes are not suitable for use on arms longer

than 250 mm.

TRUNCATED TIP

With this shape it is possible to have a better quality.

The truncated tip reduces the electrodes impression

on the sheets. The contact diameter of the electrodes

must be suitable to the thickness of the sheet itself

(see tab. 2). If the workpieces have different

thickness, the contact diameter of each electrode is

related to the thickness of the sheet it is in contact with (fig. 4).

The diameters of the

electrodes tips shown in table 2 must not

be exceeded as this could cause overheating and poor welds.

The truncated tip can be made out of the dome one by means of

a file positioned between the electrodes (see fig. 3).

The electrodes on the water-cooled arms must always have the

truncated tip.

Before starting welding it is always advisable to dress electrodes

with a fine file or emery paper.

When using the truncated tip, best results are achieved by

wrapping emery paper around a support of the same thickness

as the sheets to be welded.

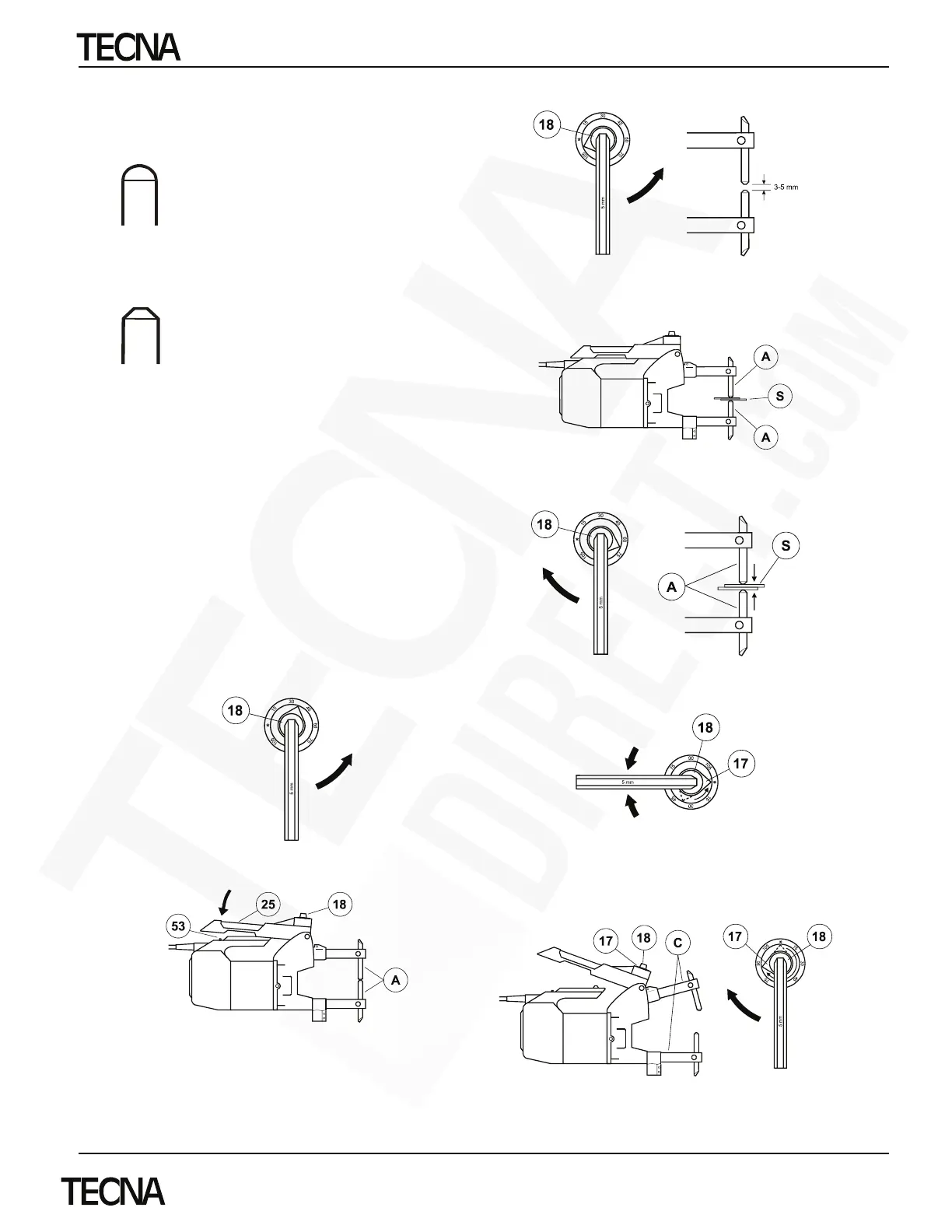

Electrode force adjustment

The welder is equipped with a force adjustment system allowing

to know the set value. Before adjusting, it is necessary to set to

zero the force indicator according to the following instructions:

1) Disconnect the welder from the mains supply.

2) Slacken screw 18 by means of 5 mm Allen key.

3) Press down lever (25) until push-button (53) is activated.

4) Slacken screw (18) until electrodes (A) are apart one from the

other a few mm.

5) Place sheets (S) to be welded between electrodes (A).

6) Turn screw (18) clockwise until electrodes (A) slightly tighten

sheets (S).

7) Keep still screw (18), and move index (17) to zero.

After setting the zero value, it is possible to directly adjust the

required electrodes force value by turning clockwise screw (18)

with arms (C) open.

7900 - 7902 / 7902P - 7903 / 7903P

DIRECT.COM

4943 Driscoll Road ¥ Warrensville Heights, OH 44146 USA

www.TECNADirect.com

PAGE 09

844-44-TECNA

DIRECT.COM

Loading...

Loading...