a positive differential switching point for direct controls (ex.Cooling

processes). Furtheremore the two Sets can be programmed independently

or dependently throught the parameter Sets Connection ("OCO"), and in

the case of set dependentlythe real regulation Set of output 2 will be

[Set1+Set2]. If output 2 is used as an alarm output, par. "OCO"

determines if the alarm is absolute or relative (in=absolute, di=relative)

and par. "HC2" determines if the alarm is low or high (H=low, C=high).

The operating mode can be also modified by means of outputs delay

parameter (par. "od") or Dynamic Set Point function, see the next

chapters for these functions.

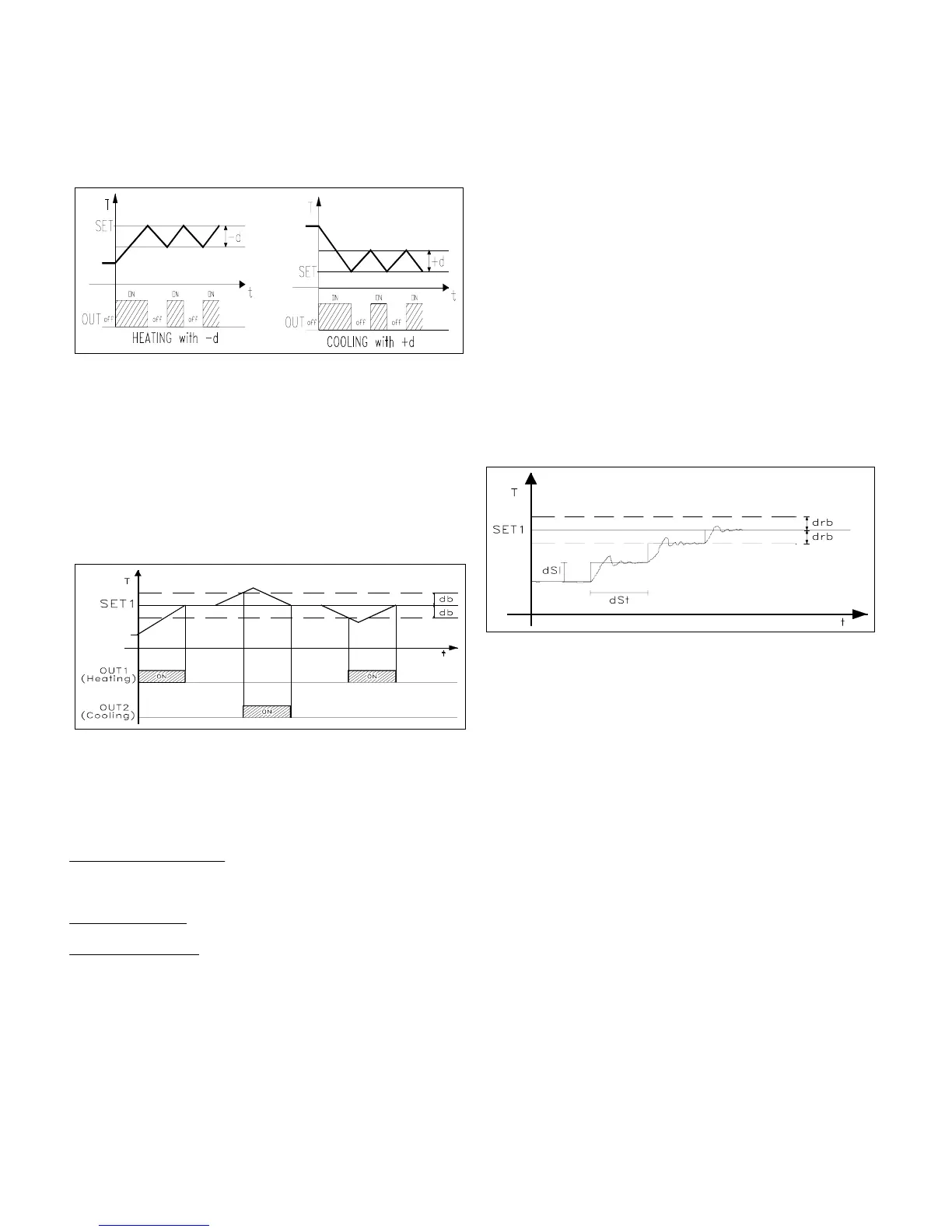

4.2 - NEUTRAL ZONE CONTROL

The Neutral Zone control mode concerns both outputs and is generally

necessary for controllig a plant that possesses an Positive regulation

element (ex. Heating, Humidification etc.) and a Negative regulation

element (ex. Cooling, Dehumidification etc.) . The functioning is

determined by the Set1 (Set2 is automatically disconnected) and Neutral

Zone (par. "db"). Subsequently the regulator operates as follows: switches

off the outputs when the process value is the same as Set, switch on the

output OUT1 when the process value is under as [Set1-db], and switch on

the output OUT2 when the process value is upper as [Set1+db]. Thus the

Positive regulation element will be connected to output OUT1, while the

Negative regulation element is at output OUT2.

4.3 - PID CONTROL AND AUTOTUNING FUNCTION

PID control mode can only be carried out through output OUT 1 while

output OUT 2 can only operates by means of ON/OFF control mode with

Set 2 independent or dependended in respect with Set 1 and can therefore

be used as an alarm (see ON/OFF regulator). The PID algorithm of the

instrument is provided to program the following parameters:

For

PROPORTIONAL term :

"Pb" - Proportional Band,

"rst" - Manual reset

"Ct" - Cycle time.

For

INTEGRAL term:

"It" - Integral time

For

DERIVATIVE term:

"dt" - Derivative time

The instrument is set on parameters relative to PID control of standard

value. If ever these should result to be unsuitable it would be advisable to

program the AUTOTUNING function. The Autotuning function permits the

automatic tuning of the PID instrument parameters.

To active the AUTOTUNING function proceed as follows :

- Set the desired "Set point".

- Set the desired parameters and especially "HC1".

- Set the parameter "Ft": Pi

- Connect the instrument with the plant

- Set the parameter "tun" : y

- Wait for the outing from the programmation

Now, the Autotuning function is activated and it's shown by the flashing of

the process value on the display. The regulator automatically tunes all the

right parameters for a correct PID control mode. Before to switch off the

instrument always wait for the end of the Autotuning process, indicated by

the return of the display on the normal functioning, . The Autotuning

procedure has been limited at a maximum time of 4 hours, after this time, if

the Autotuning is not completed the instrument automatically get out from

the procedure, showing constantly on the display the "EEE" indication. To

stop the Autotuning cycle or re-establish the normal functioning after an

error, switch off and on the instrument. The calculated values will be

automatically memorised by the instrument at the end of the Autotuning

cycle, in the PID control parameters.

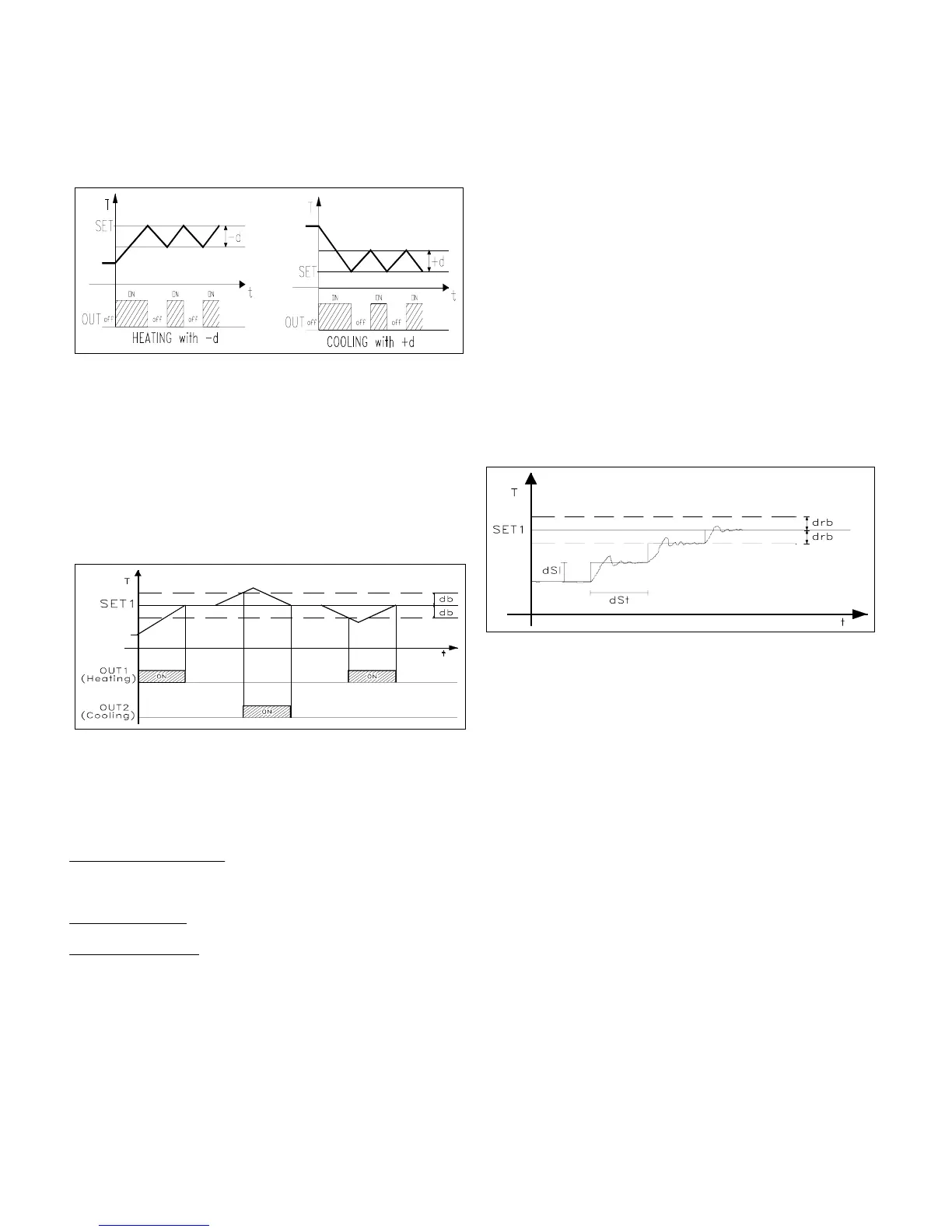

4.4 - DYNAMIC SET POINT FUNCTION

This function is only obtainable throught output OUT 1 and is usefull to

avoid starting over-extention of the process value caused by the inertness

of the system or when is wished a gradual reaching of Set value. Infact by

means of this function an automatic increase in the time of the regulation

Set from the power on-process value to the programmed Set is obtained.

The parameters to be programmed for this function are:

"drb" : Symmetrical semi-band over-lapping the Set outside from which

the function is activated.

"dSI" : Increment value of dynamic Set between two successive increments

of the dynamic Set value.

"dSt" : Time lapse between two successive increments of the dynamic Set

value.

The Dynamic Set Point function is automatically disconnected by setting

dSi = 0.

5 - PROGRAMMING

5.1 - PROGRAMMING OF SET-POINTS

Press key P then release it, led OUT1 will flash and the SET1 value will be

shown on display. To modify press key UP so as to increase value or

DOWN so as to decrease it. These keys count one digit at a time but if the

keys are pressed for over one second the value increases or decreases fast

and after two seconds the speed increases even more, so as to reach the

desired value immediately. Pressing key P again and releasing it, led

OUT2 will flash and SET2 which was previously set, will be displayed, it

can be modified by pressing keys UP or DOWN as already mentioned. The

outgoing from the Set programming mode occurs automatically by not

pressing any key for about 5 seconds, thus the process value will again be

displayed.

5.2 - PROGRAMMING OF PARAMETERS

To accede to the operating parameters it is necessary to press key P

holding it down for about 5 seconds, afterwhich the led OUT1 will flash

and the code of the first parameter will be visualized on the display. At this

point key P can be released and by pressing UP or DOWN the desired

parameter can be selected. Once the parameter on which we intended to

operate has been selected to modify it press P, while holding it down, the

set of the parameter will show up. To modify this value keep P pressed

while acting on UP or on DOWN so as to increase or decrease the value.

Once the desired value has been set release P and the selected parameter

code can be read on the display. By pressing UP or DOWN it is therefore

possible to choose another one and modify it as previously mentioned. To

outgoing from the programming mode no key is to be pressed for about 20

seconds, the instrument will automatically return to normal functioning

mode, visualizing the process value.

TECNOLOGIC - THP 96 USER MANUAL (I - GB) - Vr. 02 - ISTR 00997 - PAG. 7

Loading...

Loading...