8

EN

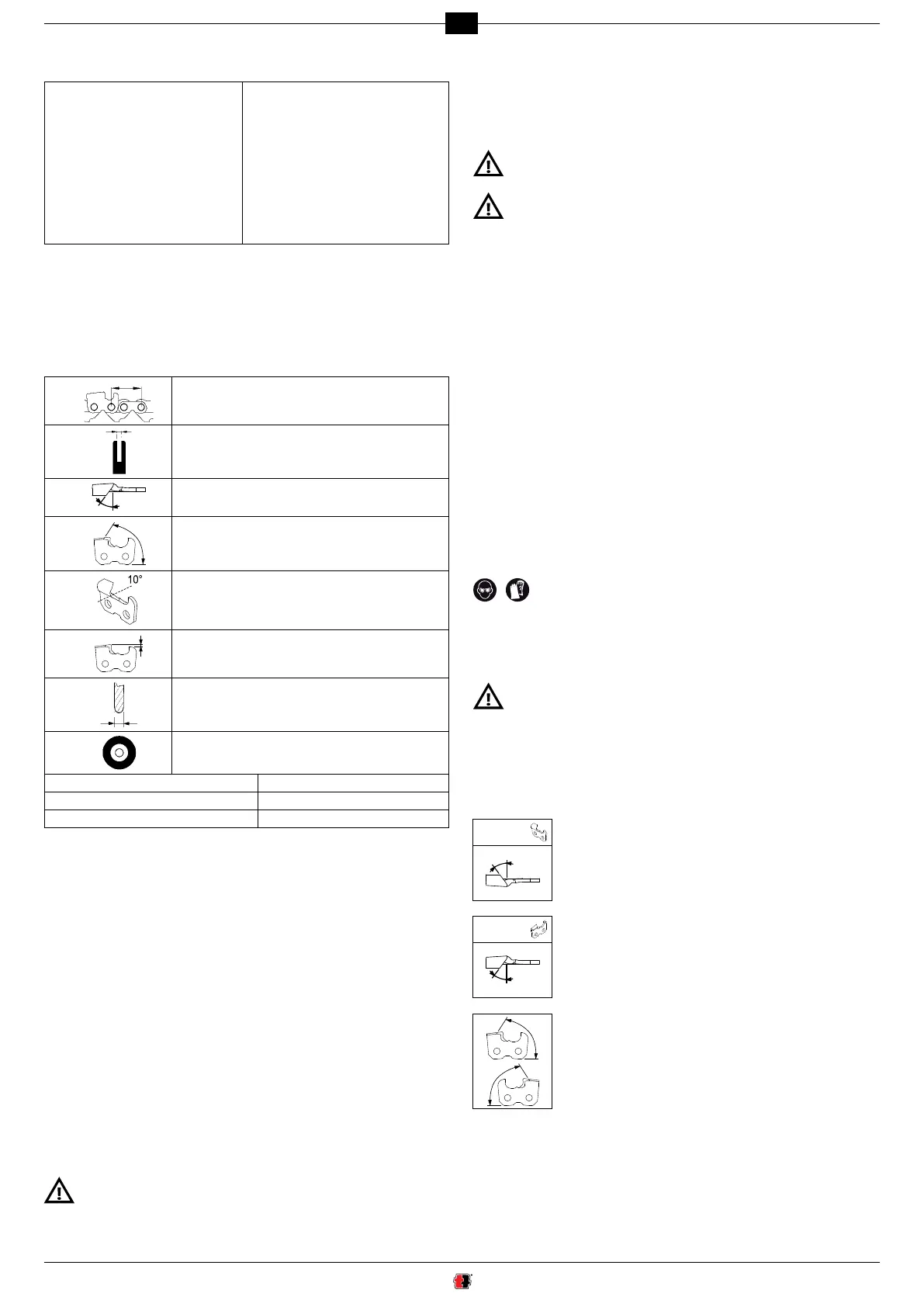

15. CHAIN INFORMATION

The chain must be completely inspected before sharpening it to make sure it is intact.

(g. 8) Cutter parts: (g. 8A) Chain parts:

1 Top part 1 Connection link

2 Top cutting angle 2 Left cutter

3 Side cutting angle 3 Right cutter

4 Sharpening recess 4 Driving link (pulling link)

5 Depth gauge 5 Rivet

6 Bit

7 Heel

8 Rivet hole

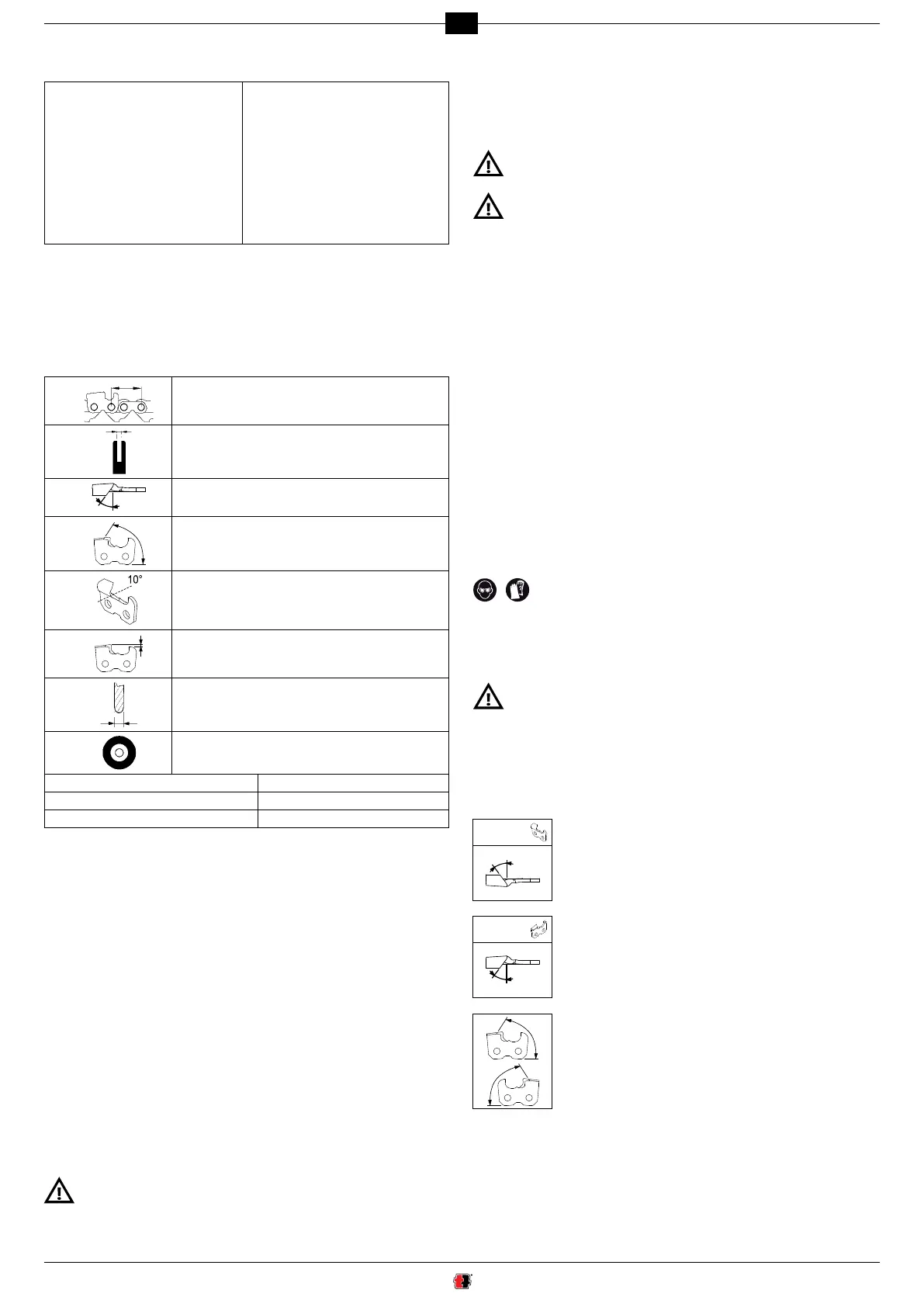

16. CHAIN IDENTIFICATION

- Before you start to sharpen, you need to know the type of chain and the relative

adjustment angles. These characteristics are written in the owner’s manual of the

chainsawonwhichthechainisttedoronthechainpack.

- Thechainidenticationcodeisusuallywrittenonthedrivinglink.

- You can also identify the chain using a template or gauge.

- Consult the CHAIN CHART at the end of this manual.

The columns in this chart provide the following information:

A

÷ 2

Chain pitch

B

Driving link width

C

Top sharpening angle (vise rotation)

D

Cutting angle (arm rotation)

E

Down angle (vise inclination)

F

Gauge depth

G

Grinding wheel thickness

H

Grinding wheel code

I Oregon chain codes N Carlton chain codes

L Windsor chain codes O Stihl chain codes

M SARP chain codes P EM chain codes

16.1 INSTRUMENTAL MEASUREMENTS (FIG.9)

a - Measure the gauge depth using the suitable shape.

b - Put the template on this side and measure the chain PITCH.

c - Put the template on this side to measure the cutter length.

d - The driving link width is measured using a suitable instrument (i.e. gauge).

17. GRINDING WHEEL WARNINGS

- Use a grinding wheel suitable for the type of chain to be sharpened; consult the

chain chart at the end of the manual.

- Do not force the grinding wheel on the hub and do not alter the centering hole

diameter.Donotusegrindingwheelsthatdonottperfectlyinplace.

- Useexclusivelycleanandperfectintacthubandangetotthegrindingwheel.

- Makesuretheoutsidediametersofthehubandangeareidentical.

18. FITTING THE GRINDING WHEEL

- Unscrew the screws V10 and remove the guard P10 (g.10).

- RemovethescrewV8andtheangeF8onthehub(g.11)

- Choose the grinding wheel based on the type of chain to be sharpened (column H

in chain chart).

- Insert and perfectly center the grinding wheel in the dedicated seat on the

hub (g.12).

- InserttheangeF8andtightenthescrewV8(g.13).

Make sure you t the ange as illustrated in g.12.

Ifthegrindingwheelisttedwiththeangestootight,itcouldbreakduring

use and put the operator at risk. To avoid such risk, tighten screw M6x25

to 7 Nm (if possible, check with dynamometric spanner).

- Reassemble the guard P10 and tighten the related screws V10 (g.14).

19. CHECKING THE ASSEMBLY OF THE GRINDING WHEEL

- Stand at the side of the grinding wheel, start the grinder and visually make sure

the grinding wheel does not oscillate sideways or crosswise, consequently causing

abnormal vibrations.

- If this should be the case, stop the appliance immediately and check if the grinding

wheelhasbeenttedcorrectly.Ifnecessary,replacethegrindingwheelwithanother

original one.

Alwayscheckafreshlyttedgrindingwheelatworkingspeedforatleastone

minute before you start grinding, standing at a safe distance and making sure

nobody else approaches the appliance.

20. ELECTRICAL CONNECTION

- Make sure the electrical system power supply complies with the values written on

the rating nameplate.

- The power supply voltage must not differ from that written on the nameplate

by ±5%.

- The connection to the electric mains must be prepared subject to current standards

in force in the country in which the appliance is used.

- The power socket used for the appliance must have an earth wire, adequate fuse

and must be protected by a differential circuit breaker with tripping sensitivity no

higher than 30 mA.

21. START-UP

- Plug the power cable into the mains.

21.1 OPERATOR POSITION (FIG.14A)

- The operator must stand in front of the machine and maintain a position that allows

him to grip the arm correctly and adjust the vice.

22. CHECKING THE GRINDING WHEEL SHAPE

- Withtheapplianceturnedoff,checkthegrindingwheelproleusingthededicated

template (g.15);ifnecessary,dressthewheeltorestorethecorrectprole.

23. GRINDING WHEEL DRESSING

Wear personal protection equipment.

- Start the grinder by turning the switch to position “1”.

- Once started, the lamp lights up to illuminate the sharpening area.

- Prolethegrindingwheelwiththedressingbrick,alwaysworkingwithextreme

caution,holdingitrmlyandsecurely(g.16).

- Stoptheapplianceandcheckiftheproleiscorrectusingthetemplate(g.17).

Contact with the grinding wheel while it spins at high speed may cause

burning and abrasions.

24. ADJUSTING THE GRINDER

24.1 SHARPENING ANGLES

- Once you have established the type of chain to be sharpened, look-up the adjust

-

ment angles (vise and arm) in the chain chart (columns C/D/E).

RH

CUTTER

24.2 SETTING THE TOP SHARPENING ANGLE (FIG.18-19)

- Loosen the knob M20.

- Turn the vise clockwise.

- Position the reference mark on the vise by the desired angle.

- Tighten knob M20 again.

LH

CUTTER

24.3 SETTING THE TOP SHARPENING ANGLE (FIG.18-20)

- Loosen the knob M20.

- Turn the vise counter clockwise.

- Position the reference mark on the vise by the desired angle.

- Tighten knob M20 again.

24.4 SETTING THE CUTTING ANGLE (FIG.21-21A)

(right and left cutters)

- Loosen the knob M23 and turn the arm towards the right. Position

the reference mark by the angle desired.

- Tighten knob M23 again.

Loading...

Loading...