13

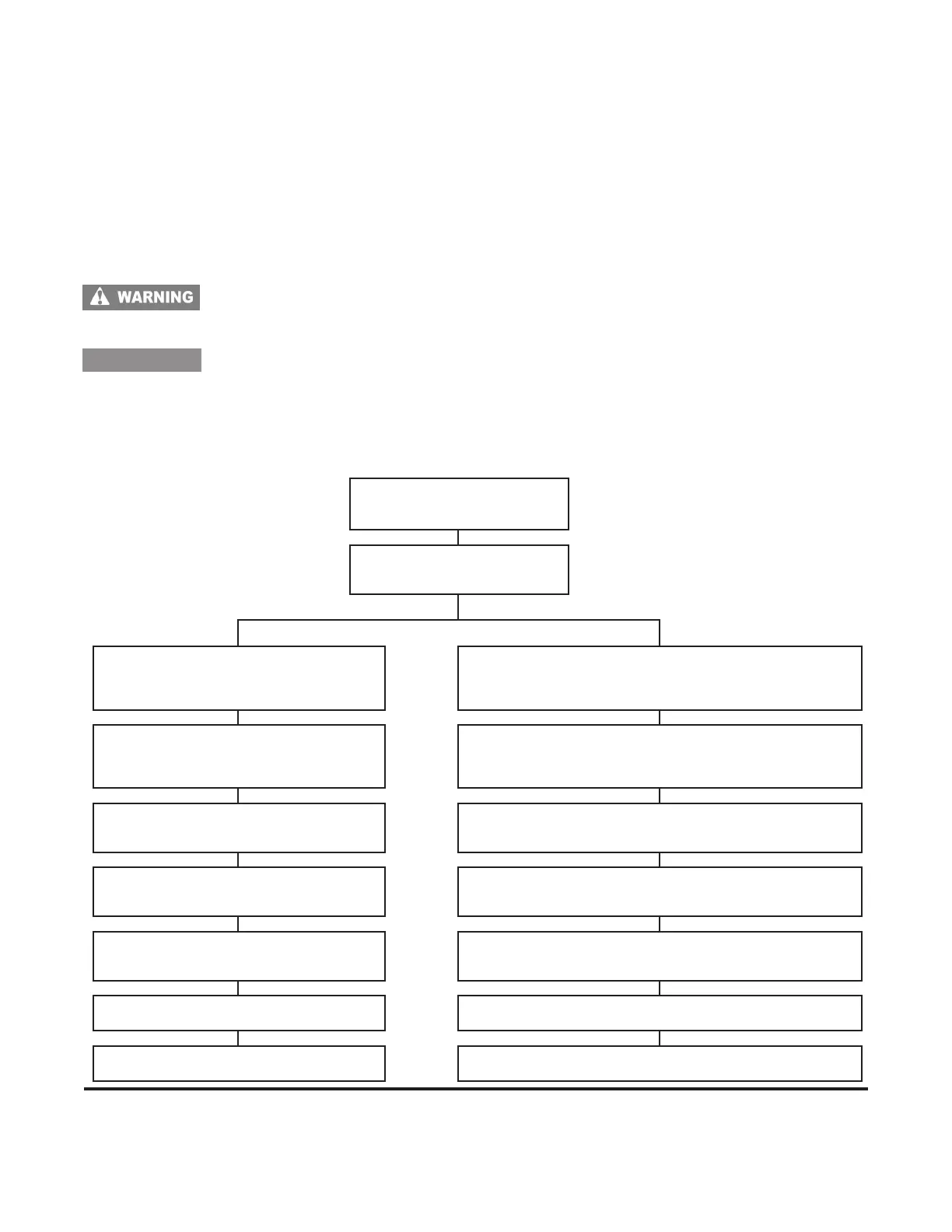

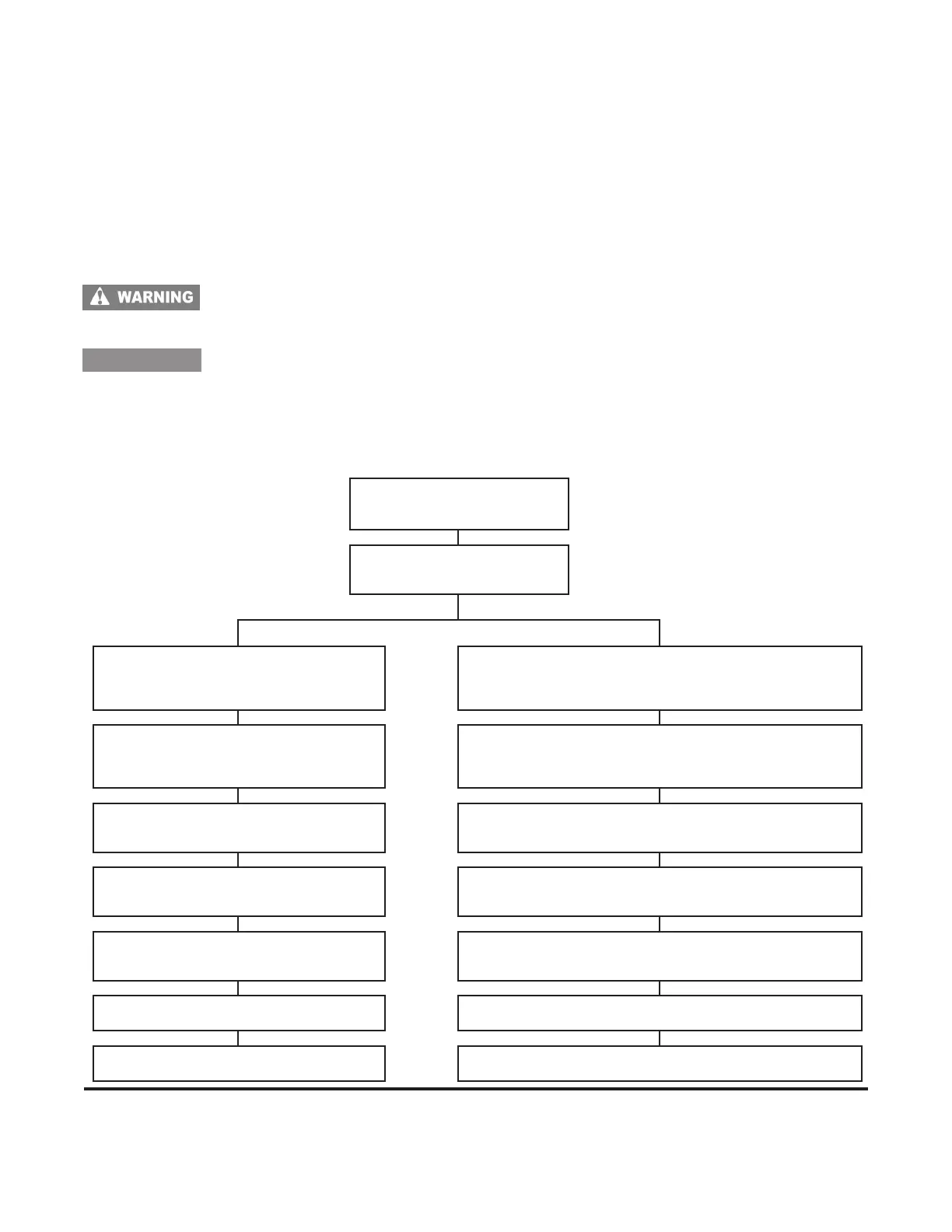

Engine Will Not

Start

Check if spark plug is

wet or dry

Wet Dry

Defective spark plug

Review with customer priming or choking

procedure (3-5 primes, if equipped, waiting 2

seconds between each prime)

Restricted air filter

If equipped with a choke, check for full travel.

Check throttle cable and control for proper

adjustment.

Improper fuel mix or stale fuel

Carburetion problem*

(bad bowl gasket)

Sheared or partially sheared

flywheel key

Check fuel supply and fuel cap vent

Carburetion problems due to

flooding, over priming, etc.*

Restriction in fuel system

(filter

, screen)

Ignition System Poor compression

Crankcase seals or gaskets leaking Damaged reed, port plugs, seals or gaskets

Should more extensive repair be needed, we recommend you contact a local Tecumseh Servicing Dealer for repair.

Repair manuals are also available from your local dealer or direct from Tecumseh. A complete list of the available

manuals can be found at the end of this book.

NOTE: Refer to Technician's Handbook for a more detailed list of remedies.

Two Cycle Troubleshooting

The following is provided as a basic troubleshooting guide. Its use requires a complete review of all conditions

and symptoms. Always examine the exterior for clues: leaks, excessive dirt, or obvious damage. Some repairs will

require the assistance of a Tecumseh Servicing Dealer.

Preparation

Before troubleshooting any system problem, see original equipment manufacturer’s (O.E.M.) instructions.

Make your troubleshooting easier by preparing as follows:

• Work in a clean, well-lighted place.

• Keep proper tools and materials nearby.

• Keep an adequate supply of clean petroleum-based solvent.

To reduce the risk of serious injury or death from fires and/or explosions, NEVER use flammable

solvents (e.g., gasoline) to clean serviceable parts. Use a water-based, non-flammable solvent

such as Tecumseh Degreaser Cleaner.

NEVER use compressed air to clean debris from yourself or your clothing. When using compressed

air to clean or dry serviceable parts:

• Wear appropriate eye protection.

• Use only approved air blow nozzles.

CAUTION

• Air pressure must not exceed 30psi (206kPa).

• Shield yourself and bystanders from flying debris.

FUEL SYSTEM

another free manual from www.searstractormanuals.com

Loading...

Loading...