MAINTENANCE INSTRUCTIONS

98-01580-EN-R0_A4LT-E-ChemSaver-MaintenanceInstructions-TB.docx

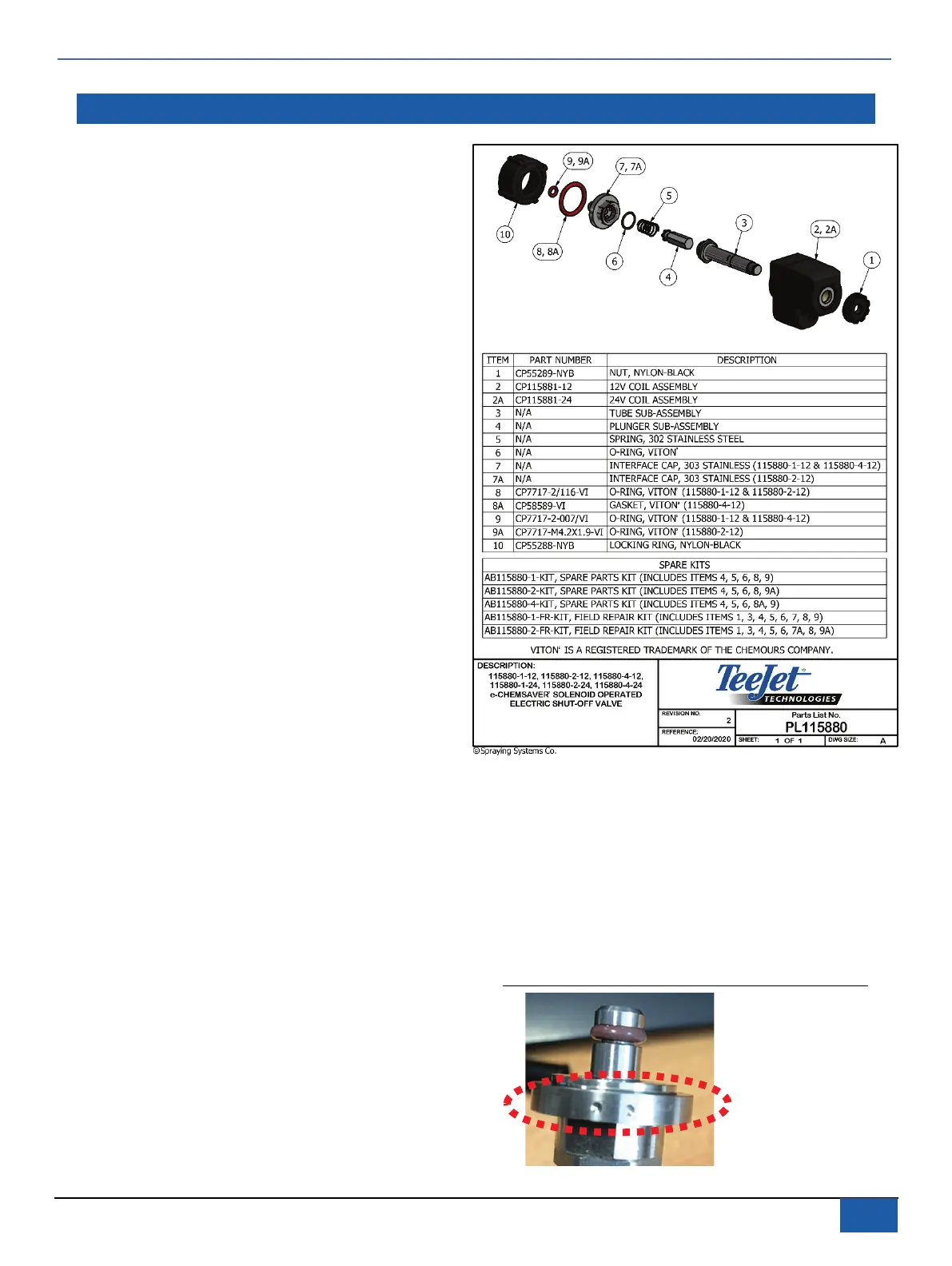

SOLENOID DISASSEMBLY AND REASSEMBLY

NOTE: O-rings (6, 8, 9) should be handled with care as they can be

damaged/deformed.

Disassembly

1.

Loosen and remove the nylon Nut (1).

2.

Separate the Coil Assembly (2) from the rest of the

Tube/Plunger Assembly (3-10).

3.

Remove the Locking Ring (10).

4.

Using e-ChemSaver (CP116231-NYB) wrench or pliers to grip

the stainless steel Interface Cap (7), loosen the Tube Sub-

Assembly (3) using a 14 mm / 9/16" or adjustable wrench.

All repairable parts should be accessible at this point. The Plunger

Sub-Assembly (4), stainless steel Spring (5), and O-rings (6, 8, 9)

can be replaced without further disassembly.

Reassembly

5.

During reassembly, place the Plunger Sub-Assembly (4) and

stainless steel Spring (5) in the Tube Sub-Assembly (3).

NOTE: The Plunger Sub-Assembly (4) should be orientated with

the black insert facing outward (visible) when placed in

the Tube Sub-Assembly (3).

6.

While compressing the Spring (5), thread the Tube/Plunger

Assembly (3-10) to the stainless steel Interface Cap (7) and

tighten using a wrench and pliers.

►

Optional: Apply 1 drop of Loctite Blue 243 to the threads

of the Interface Cap (7) and Tube Sub-Assembly (3).

►

Torque Specifications: Tighten Interface Cap (7) and

Tube Sub-Assembly (3) to 1.36 N-m / 12 in-lbs.

7.

Return the Locking Ring (10) to its original position and slide the

Tube/Plunger Assembly (3-10) through the Coil Assembly (2).

NOTE: The Coil Assembly (2) should be orientated with the

SuperSeal 1.5 connector facing away from the Interface

Cap (7).

8.

Tighten the nylon Nut (1) to the Tube/Plunger Assembly (3-10).

Verification After Reassembly

9.

Lubricate O-ring (9) before re-attaching the e-ChemSaver to the

nozzle body.

10.

Attach the solenoid on the nozzle body and inspect for leaks

when system is on.

RECOMMENDED: At the time of installation, prior to plugging in the

connector, spray a sufficient quantity of CorrosionX

®

,

CorrosionX

®

Heavy Duty, or CorrosionX

®

Aviation corrosion

prevention compound into the connector to wet the

terminals.

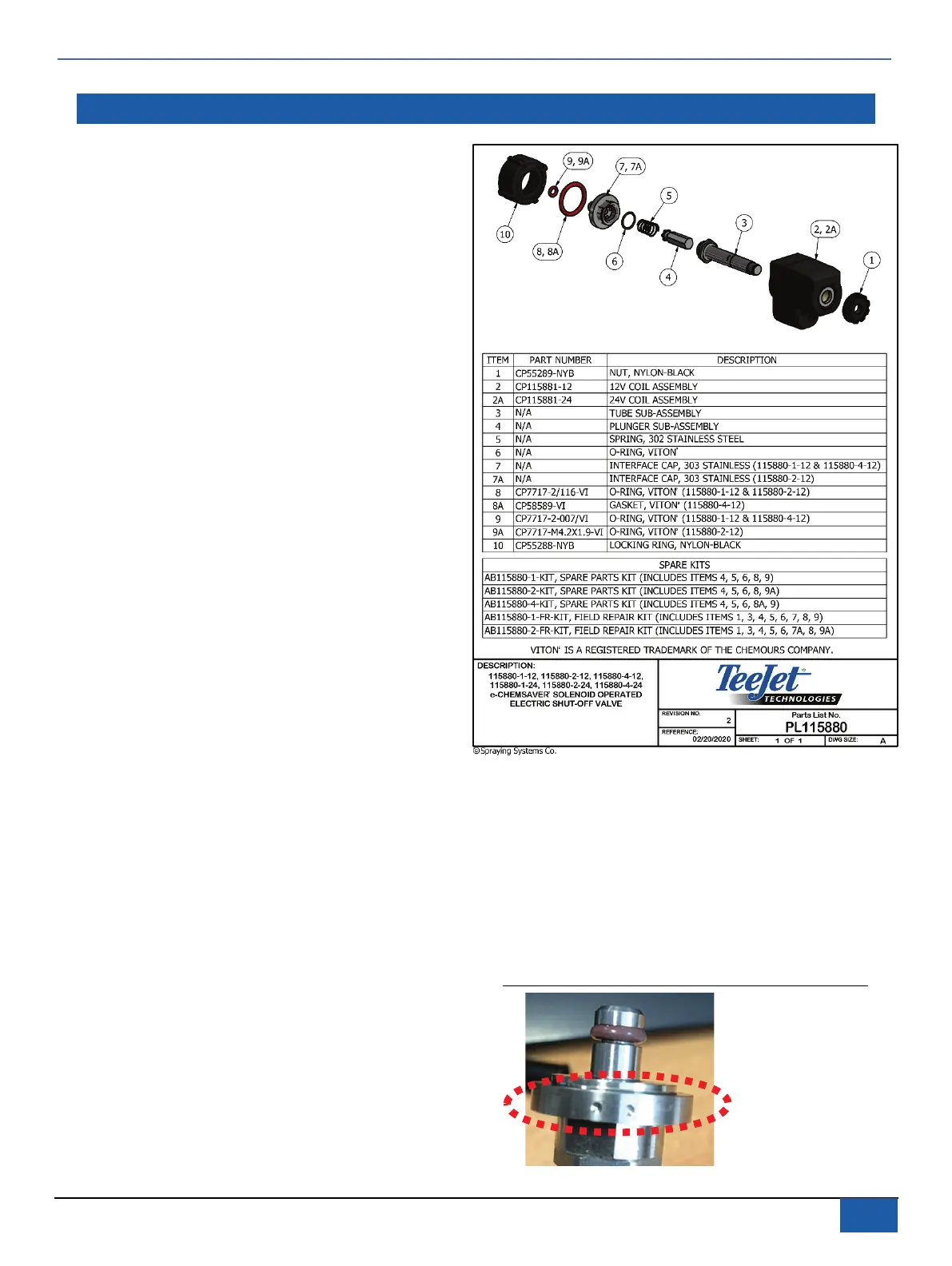

e-ChemSaver Models

If, for any reason, the change of the complete e-ChemSaver is

mandatory, there exist 3 different models. For choosing the right one,

refer to the interface cap (7) indicating the number of different points

marked on it.

•

1 MARK – Reference 115880-1-12.

•

2 MARKS – Reference 115880-2-12. (above image)

•

4 MARKS – Reference 115880-4-12.

Figure 1:

Model Markings

Loading...

Loading...