Installation (Continued)

2. When the pump is set away from the

points of water use, the discharge

pipe size should be increased to

reduce pressure losses caused by

friction.

• Up to 100 ft run: Same size as

pump discharge port.

• 100 ft. to 300 ft run: Increase one

pipe size.

• 300 ft. to 600 ft run: Increase two

pipe sizes.

PRESSURE TANK INSTALLATION

The Pressure Tank provides a reservoir

of water under pressure and maintains

a cushion of air pressure to prevent

pipe hammering and possible damage

to plumbing components. When water

is drawn off through house fixtures, the

pressure in the tank is lowered and the

pressure switch starts the pump.

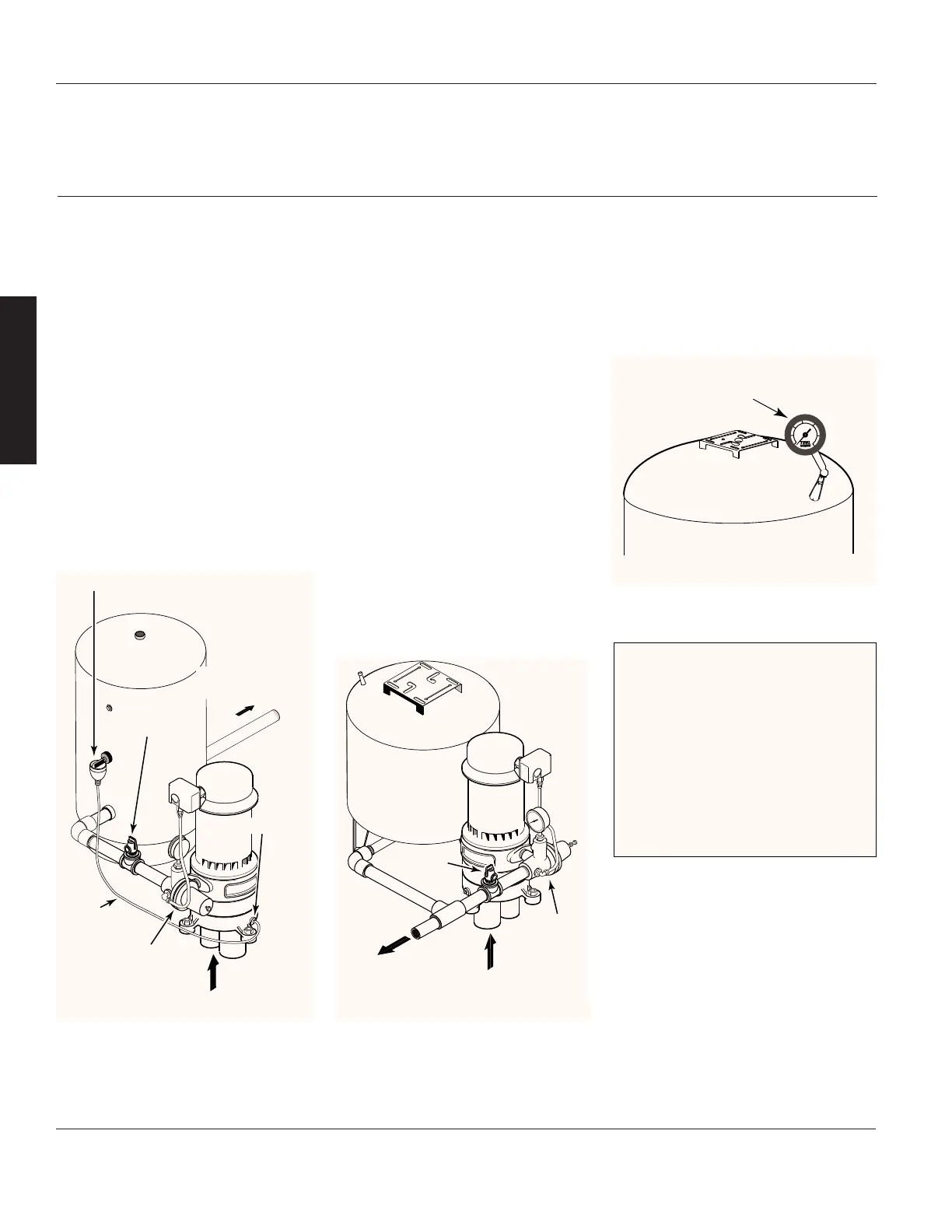

STANDARD TANK CONNECTION

When a standard tank is used, an air

volume control (AVC) adds air to the

tank when it is needed. See Figure 3

for typical standard tank installation. To

connect AVC to pump, thread a 1/4”

compression fitting into tapped hole on

the front of the pump. Cut tubing to

length to reach AVC; assemble to fitting

on pump and to AVC on tank. See

installation instructions provided with

tank and AVC for details.

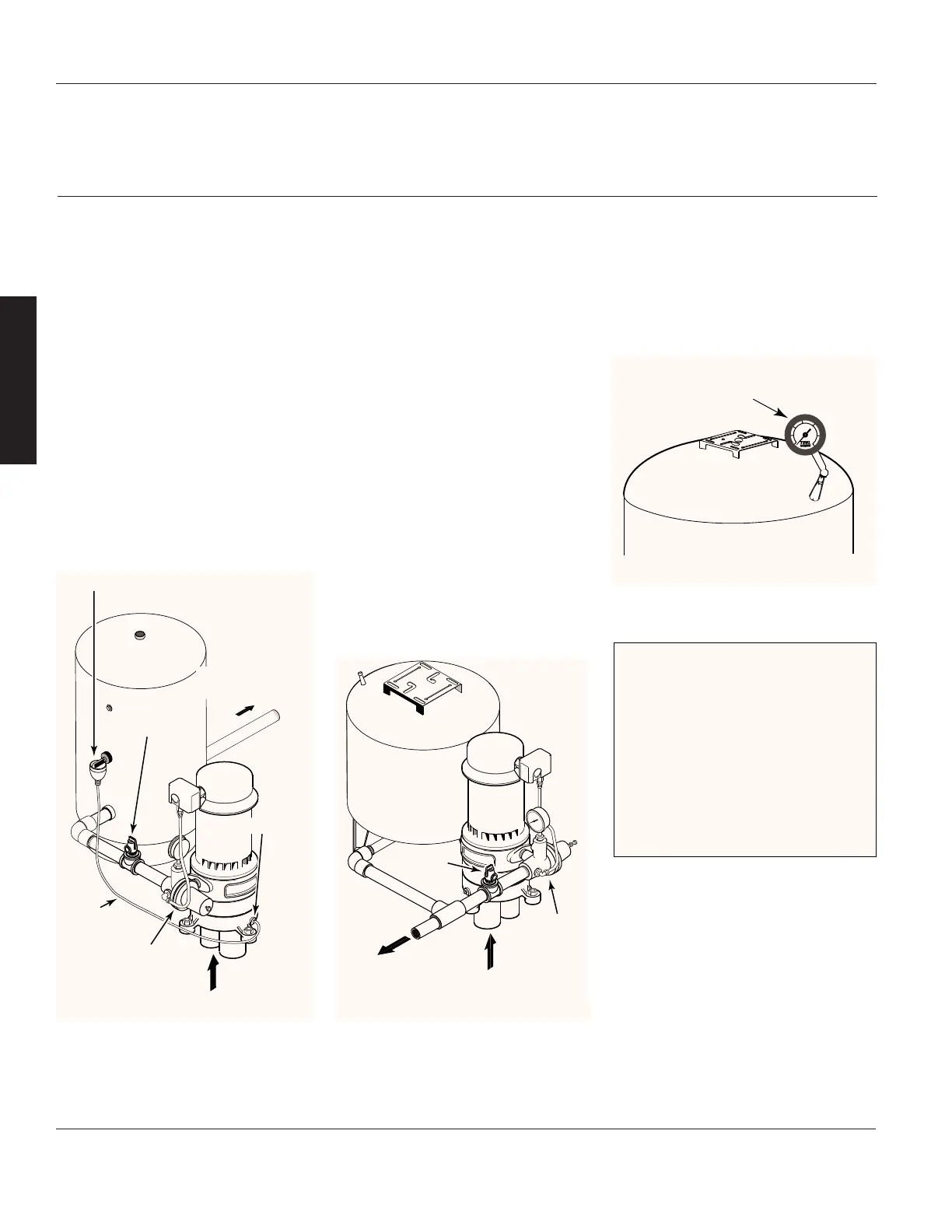

PRECHARGED TANK CONNECTION

When a precharged tank is used, no

AVC is necessary. See Figure 4 for

typical precharged tank installation. A

precharged tank contains a factory

provided air charge.

IMPORTANT: Your pump pressure

switch is set for a 30-50 psi range and

requires a tank pre-charge of 28 psi for

proper operation (See Figure 5 below

and Tank Owner’s Manual). An annual

check on tank air charge is

recommended.

8

Teel Operating Instructions and Parts Manual

3P740A, 4P037, 4P038, 4P039 and 4RJ96A

Teel One, Two, and Three Stage

Vertical Jet Pumps

®

E

N

G

L

I

S

H

SEALING PIPE JOINTS

Use teflon tape or a teflon-

based pipe joint compound to

seal the joints in the suction

pipe. Make sure that all pipe

joints in the suction pipe are air-

tight as well as water tight.

If the suction pipe can suck air,

the pump will not be able to

pull water from the well.

Loading...

Loading...