SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

Specifications subject to change without notice.

14 440 04 4201 01

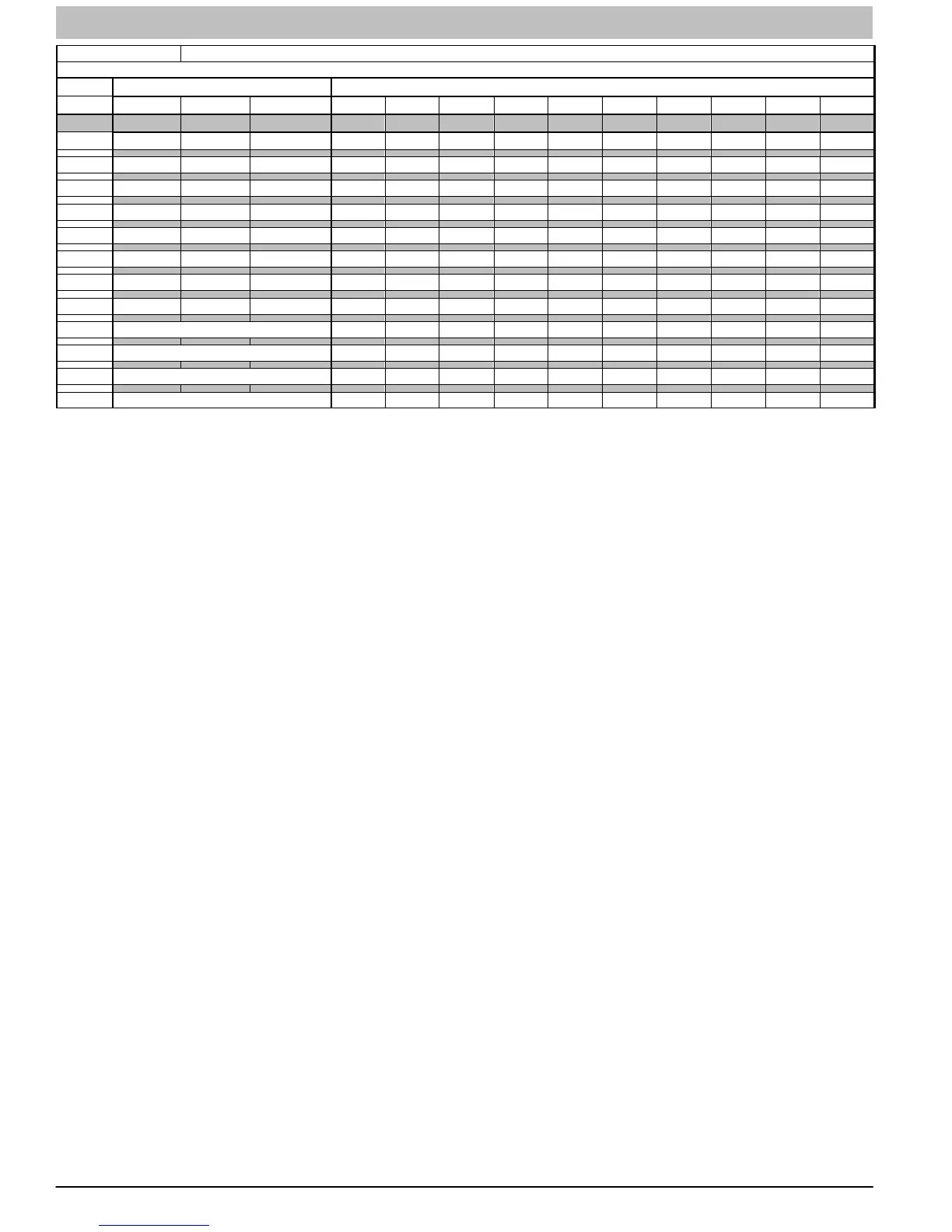

Table 4 (CONT.) COOLING

4

AND HEATING AIR DELIVERY - CFM (Bottom Return

5

with Filter)

(SW1-5 and SW4-3 set to OFF, except as indicated. See notes 1 and 2)

Unit Cooling Switch Settings External Static Pressure (ESP) in. w.c.

Size SW2-3 SW2-2 SW2-1 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

120-22

OFF OFF OFF 1850 1855 1860 1855 1850 1830 1805 1775 1750 1730

OFF OFF ON 765 745 740 705 680

OFF ON OFF 930 925 915 900 885

OFF ON ON 1095 1100 1110 1105 1085

ON OFF OFF 1265 1255 1265 1280 1275 1285 1270 1260 1250 1230

ON OFF ON 1465 1455 1470 1465 1465 1470 1455 1450 1435 1415

ON ON OFF 1850 1855 1860 1855 1850 1830 1805 1775 1750 1730

ON ON ON 2200 2200 2200 2190 2185 2170 2145 2085 1990 1890

Maximum Clg Airflow

2

2200 2200 2200 2190 2185 2170 2145 2085 1990 1890

Maximum Heat Airflow

3

1815 1820 1825 1820 1815 1795 1775 1745 1720 1700

Intermediate Heat Airflow

3

1095 1100 1110 1105 1085

Minimum Heat Airflow

3

905 900 890 875 855

1. Nominal 350 CFM/ton cooling airflow is delivered with SW1-5 and SW4-2 set to OFF.

Set SW1-5 to ON for nominal 400 CFM/ton (+15% airflow).

Set SW4-3 to ON for nominal 325 CFM/ton (-7% airflow).

Set both SW1-5 and SW4-3 to ON for nominal 370 CFM/ton (+7% airflow).

2. Maximum cooling airflow is achieved when switches SW3-1, SW3-2, SW3-3 and SW1-5 are set to ON, and SW4-3 is set to OFF.

3. All heating CFM’s are when minimum/intermediate heat rise adjustment switch (SW1-3) and comfort/efficiency adjustment switch (SW1-4)

are both set to OFF.

4. Ductwork must be sized for maximum heating CFM within the operational range of ESP. Operation within the blank areas of the chart is not

recommended because maximum heat operation will be above 1.0 ESP.

5. All airflows on 21” casing size furnaces are 5% less on side return only installations.

6. Side returns for 24.5” casing sizes require two sides, or side and bottom, to allow sufficient airflow at the return of the furnace.

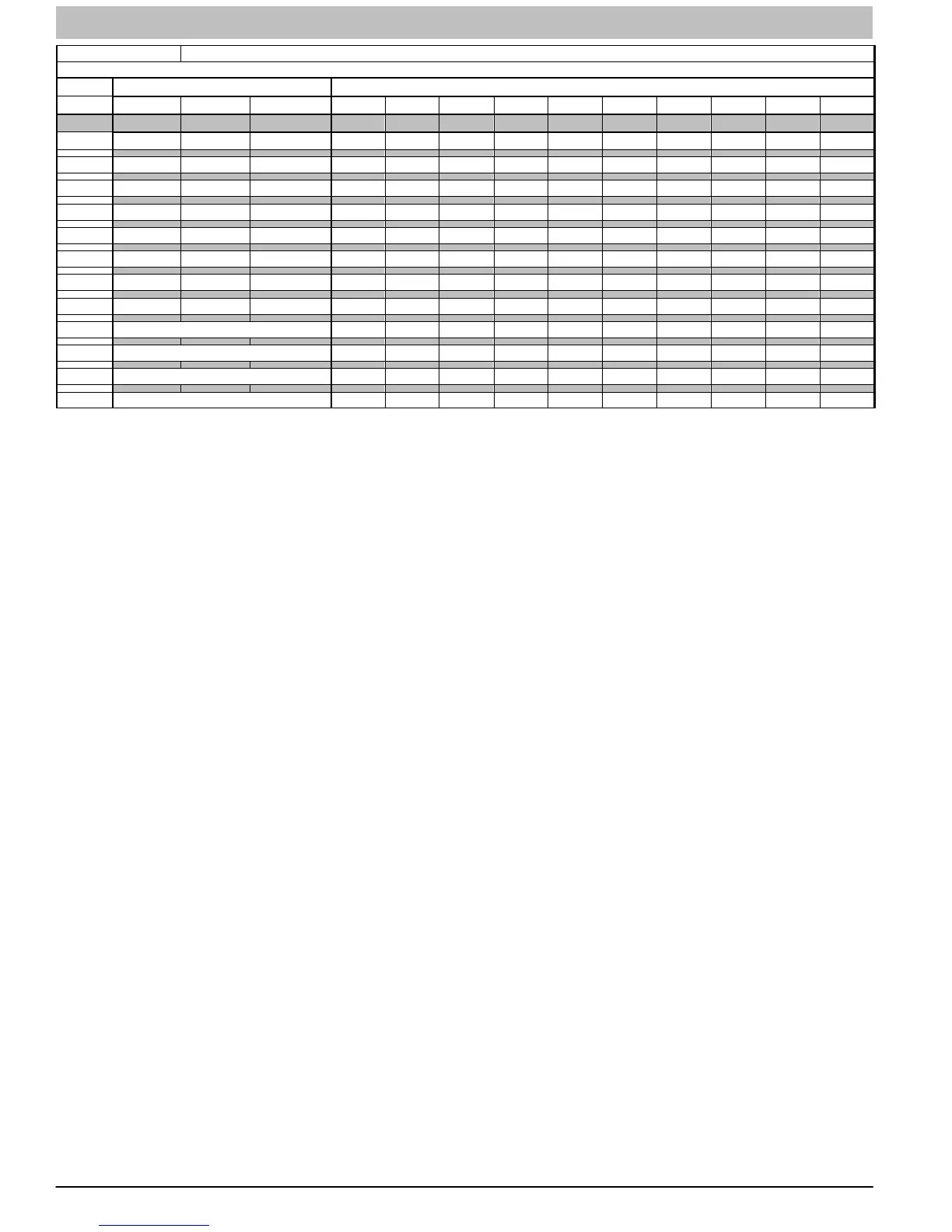

Table 5

Gas Rate (CU ft./hr)

SECONDS G

FOR 1 REVOLUTION

SIZE OF TEST DIAL

SECONDS

FOR 1 REVOLUTION

SIZE OF TEST DIAL

1 Cu Ft. 2 Cu Ft. 5 Cu Ft. 1 Cu Ft. 2 Cu Ft. 5 Cu Ft.

10 360 720 1800 50 72 144 360

11 327 655 1636 51 71 141 355

12 300 600 1500 52 69 138 346

13 277 555 1385 53 68 136 340

14 257 514 1286 54 67 133 333

15 240 480 1200 55 65 131 327

16 225 450 1125 56 64 129 321

17 212 424 1059 57 63 126 316

18 200 400 1000 58 62 124 310

19 189 379 947 59 61 122 305

20 180 360 900 60 60 120 300

21 171 343 857 62 58 116 290

22 164 327 818 64 56 112 281

23 157 313 783 66 54 109 273

24 150 300 750 68 53 106 265

25 144 288 720 70 51 103 257

26 138 277 692 72 50 100 250

27 133 267 667 74 48 97 243

28 129 257 643 76 47 95 237

29 124 248 621 78 46 92 231

30 120 240 600 80 45 90 225

31 116 232 581 82 44 88 220

32 113 225 563 84 43 86 214

33 109 218 545 86 42 84 209

34 106 212 529 88 41 82 205

35 103 206 514 90 40 80 200

36 100 200 500 92 39 78 196

37 97 195 486 94 38 76 192

38 95 189 474 96 38 75 188

39 92 185 462 98 37 74 184

40 90 180 450 100 36 72 180

41 88 176 439 102 35 71 178

42 86 172 429 104 35 69 173

43 84 167 419 106 34 68 170

44 82 164 409 108 33 67 167

45 80 160 400 110 33 65 164

46 78 157 391 112 32 64 161

47 76 153 383 116 31 62 155

48 75 150 375 120 30 60 150

49 73 147 367

Loading...

Loading...