SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

Specifications subject to change without notice.

440 04 4201 01 5

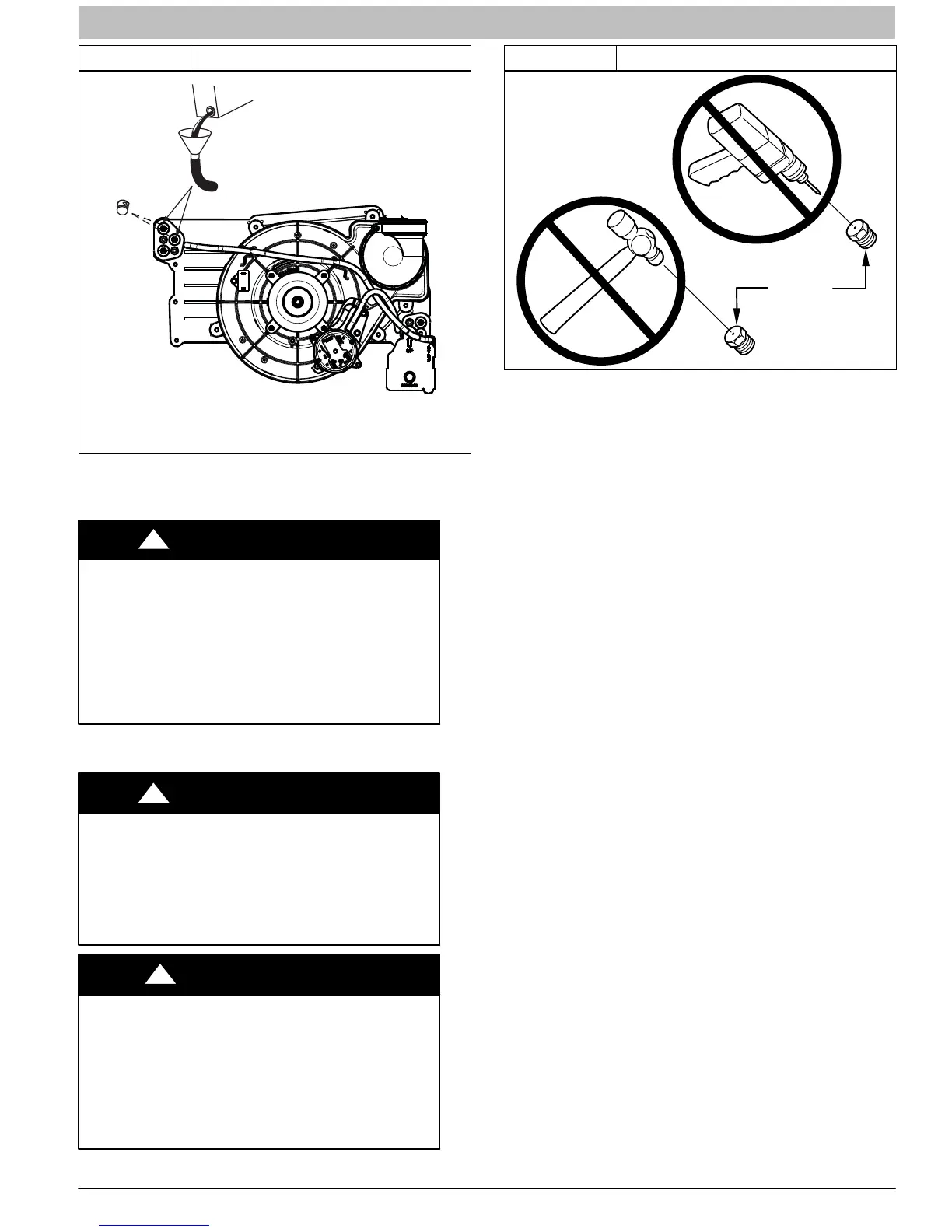

Figure 1 Priming Condensate Drain

L11F065

Representative drawing only, some models may vary in appearance.

Purge Gas Lines

If not previously done, purge the lines after all connections

have been made and check for leaks.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

!

WARNING

Adjustments

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

DO NOT bottom out gas valve regulator adjusting

screw. This can result in unregulated manifold

pressure and result in excess overfire and heat

exchanger failures.

!

WARNING

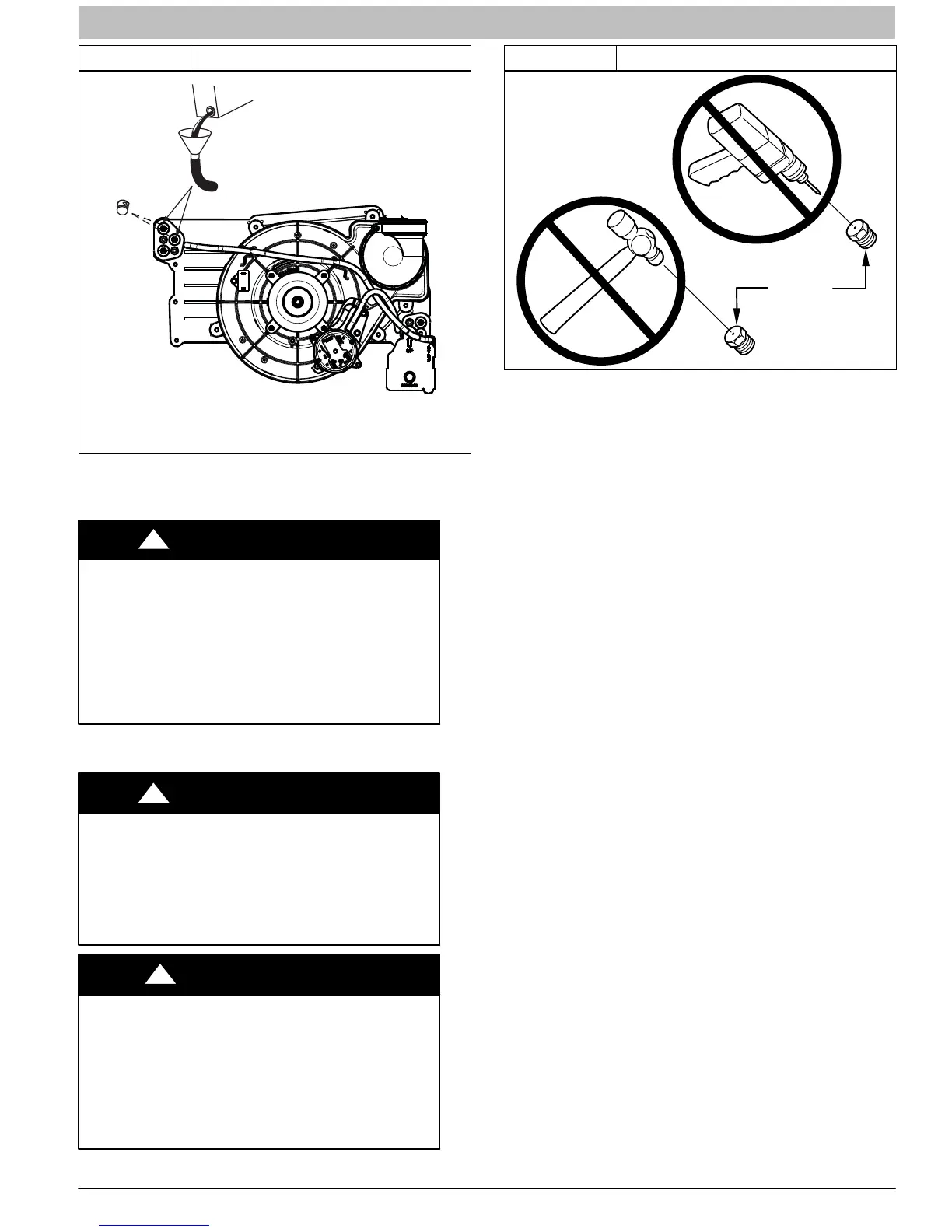

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in reduced

furnace life.

DO NOT redrill orifices. Improper drilling (burrs,

out−of−round holes, etc.) can cause excessive burner

noise and misdirection of burner flames. This can

result in flame impingement of heat exchangers,

causing failures. (See Figure 2)

CAUTION

!

Figure 2 Orifice Hole

A93059

BURNER

ORIFICE

For proper operation and long term reliability, the Furnace input

rate must be within +2 percent of input rate on furnace rating

plate.

The gas input rate on rating plate is for installations at altitudes

up to 2000 ft. (609.6M).

In the USA., the input rating for altitudes above 2000 ft. (610 M)

must be reduced by 2 percent for each 1000 ft. (304.8M) above

sea level refer to Table 1.

In Canada, the input rating must be derated by 5 percent for

altitudes of 2000 ft. (610 M) to 4500 ft. (1372 M) above sea

level.

To adjust manifold pressure to obtain the proper input rate, first,

determine if the furnace has the correct orifice installed. At

higher altitudes or different gas heat contents, it may be

necessary to change the factory orifice to a different orifice.

Tables have been provided in the furnace installation

instructions to match the required orifice to the manifold

pressure to the heat content and specific gravity of the gas. To

do this:

a. Obtain average heat value (at installed altitude) from

local gas supplier.

b. Obtain average specific gravity from local gas supplier.

c. Find installation altitude range for your installation in the

manifold pressure tables. (See Table 3)

d. Find closest natural gas heat value and specific gravity in

Table 3.

e. Follow heat value and specific gravity lines to point of

intersection to find orifice size and maximum and

minimum manifold pressure settings for proper operation.

f. Check and verify burner orifice size in furnace. Never

assume orifice size. Always check and verify.

g. Replace orifice with correct size, if required by Table 3.

Use only factory−supplied orifices. See EXAMPLE.

EXAMPLE: 0 − 2000 ft. (0 − 609.6M) altitude

Heating value = 1050 Btu/cu ft.

Specific gravity = 0.62

Therefore: Orifice No. 44

Manifold pressure: 3.4−in. w.c. for maximum heat, 0.55−in. w.c.

for minimum heat.

* Furnace is shipped with No. 44 orifices. In this example, all

main burner orifices are the correct size and do not need to be

changed to obtain proper input rate.

Loading...

Loading...