SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MAC

Specifications subject to change without notice.

440 04 4201 01 7

FURNACE OVERHEATING HAZARD

Failure to follow this caution may result in shortened

furnace life.

Set air temperature rise within limits specified on the

rating plate to prevent reduced life of furnace

components. Operation is within a few degrees of the

mid−point of rise range when setup switch SW1−4 is

OFF.

CAUTION

!

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in overheating

the heat exchangers or condensing flue gases in heat

exchanger areas not designed for condensate.

Temperature rise must be within limits specified on

unit rating plate. Operation is within a few degrees of

midpoint of rise range when setup switch SW1−4 is

OFF.

CAUTION

!

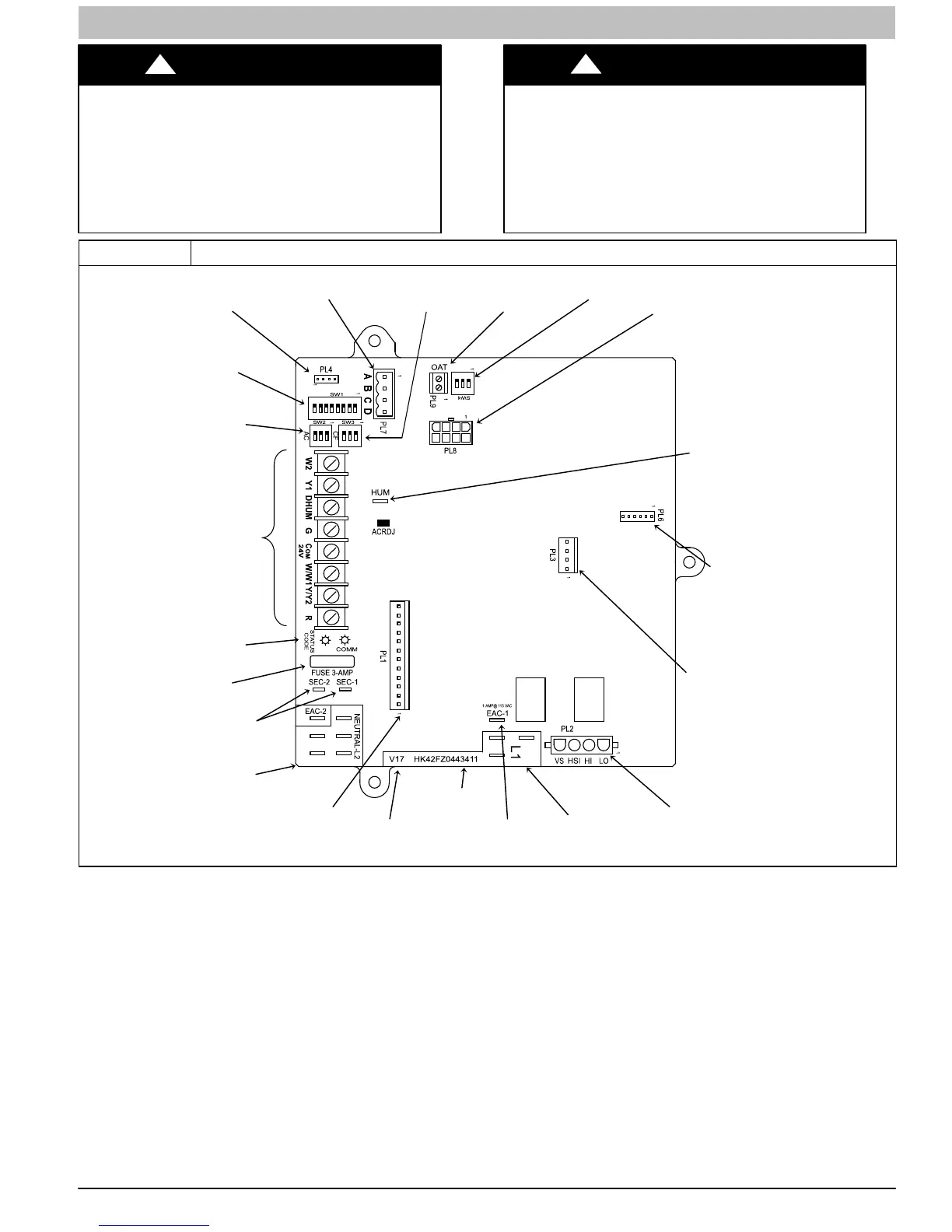

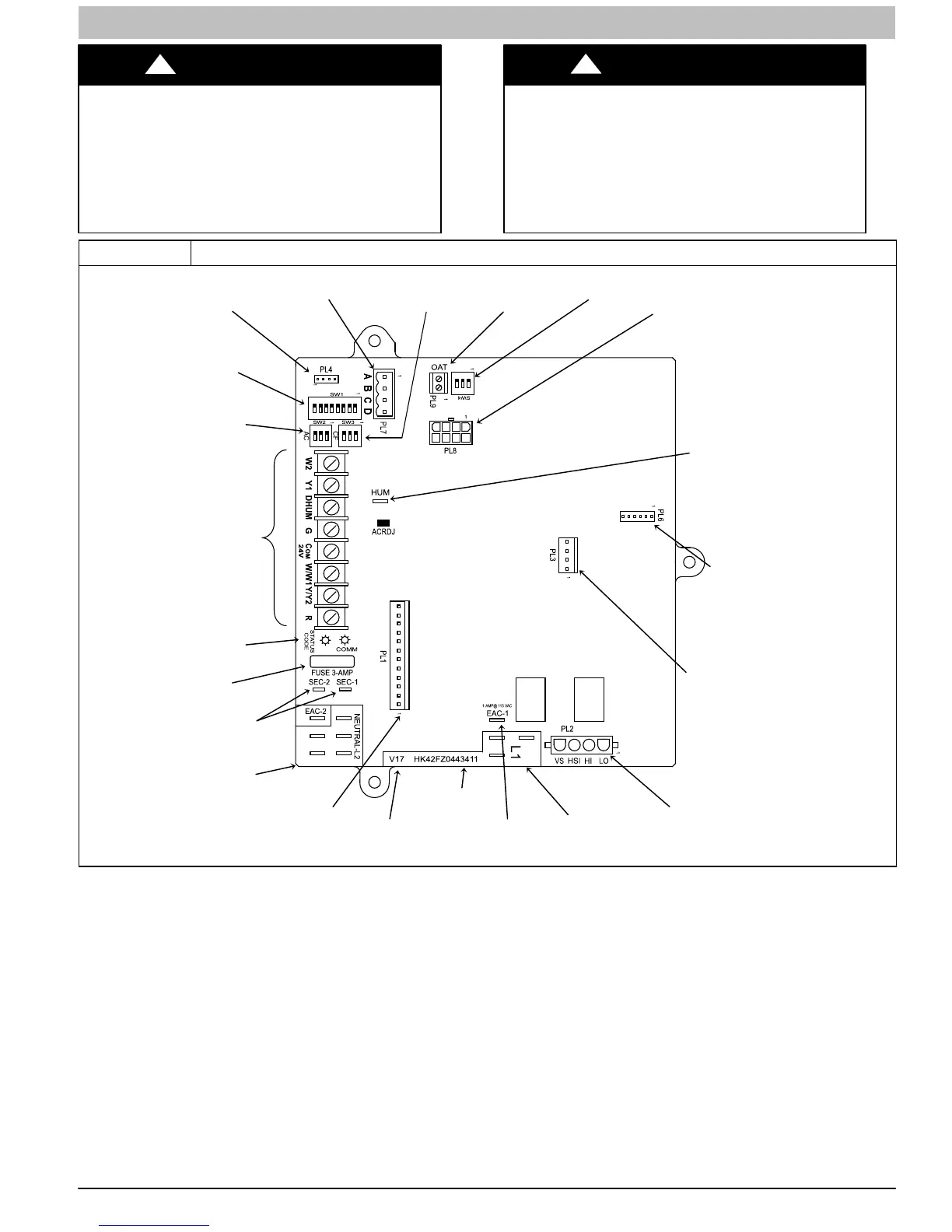

Figure 3 Variable Speed Furnace Control for ECM Blower Motor (Modulating)

TERMINALS

PL2 – HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

115-VAC (L2) NEUTRAL

CONNECTIONS

115-VAC (L1) LINE

VOLTAGE CONNECTIONS

EAC-1 TERMINAL

(115-VAC 1.0 AMP MAX.)

PL1 – LOW VOLTAGE MAIN

HARNESS CONNECTOR

HARNESS

CONNECTOR

TRANSFORMER 24-VAC

CONNECTIONS

STATUS AND COMM

LED LIGHTS

BLOWER OFF-

AIR CONDITIONING

(A/C) AIRFLOW

SETUP SWITCHES

CONTINUOUS FAN

(CF) AIRFLOW

SETUP SWITCHES

A

-

FLASH

UPGRADE

CONNECTOR

(FACTORY

ONLY)

PART NUMBER AND

DATE CODE WWYY

GAS VALVE

L11F061

Adjust Temperature Rise

When setup switch SW1-4 is ON, operation will be near the

high end of the rise range for improved comfort.

Furnace must operate within ranges of temperature rise

specified on the furnace rating plate. Determine air temperature

rise as follows:

1. Place thermometers in return and supply ducts as near

furnace as possible. Be sure thermometers do not see

heat exchanger so that radiant heat does not affect

readings. This practice is particularly important with

straight-run ducts.

2. When thermometer readings stabilize, subtract return-air

temperature from supply-air temperature to determine air

temperature rise.

NOTE: Temperature rise can be determined for Minimum Heat,

Intermediate Heat and Maximum Heat operation by locking the

furnace in each mode of operation. The mode of operation is

based on the position of Set-up switch SW1-2 and SW4-2 on

the furnace control board.

The furnace is capable of automatically providing proper airflow

to maintain the temperature rise within the range specified on

furnace rating plate. If temperature rise is outside this range,

proceed as follows:

a. Check gas input for Minimum, Intermediate, and

Maximum heat operation.

b. Check derate for altitude if applicable.

c. Check all return and supply ducts for excessive

restrictions causing static pressure greater than 0.5-in.

w.c.

d. Ensure Min/Int Heat Rise Adjust switch SW1−3 on

furnace control is in ON position when a bypass

humidifier is used. (See Figure 3 for switch location.)

e. Check Troubleshooting Guide for Variable−Speed Step

Modulating Condensing Furnaces.

Loading...

Loading...