8-3

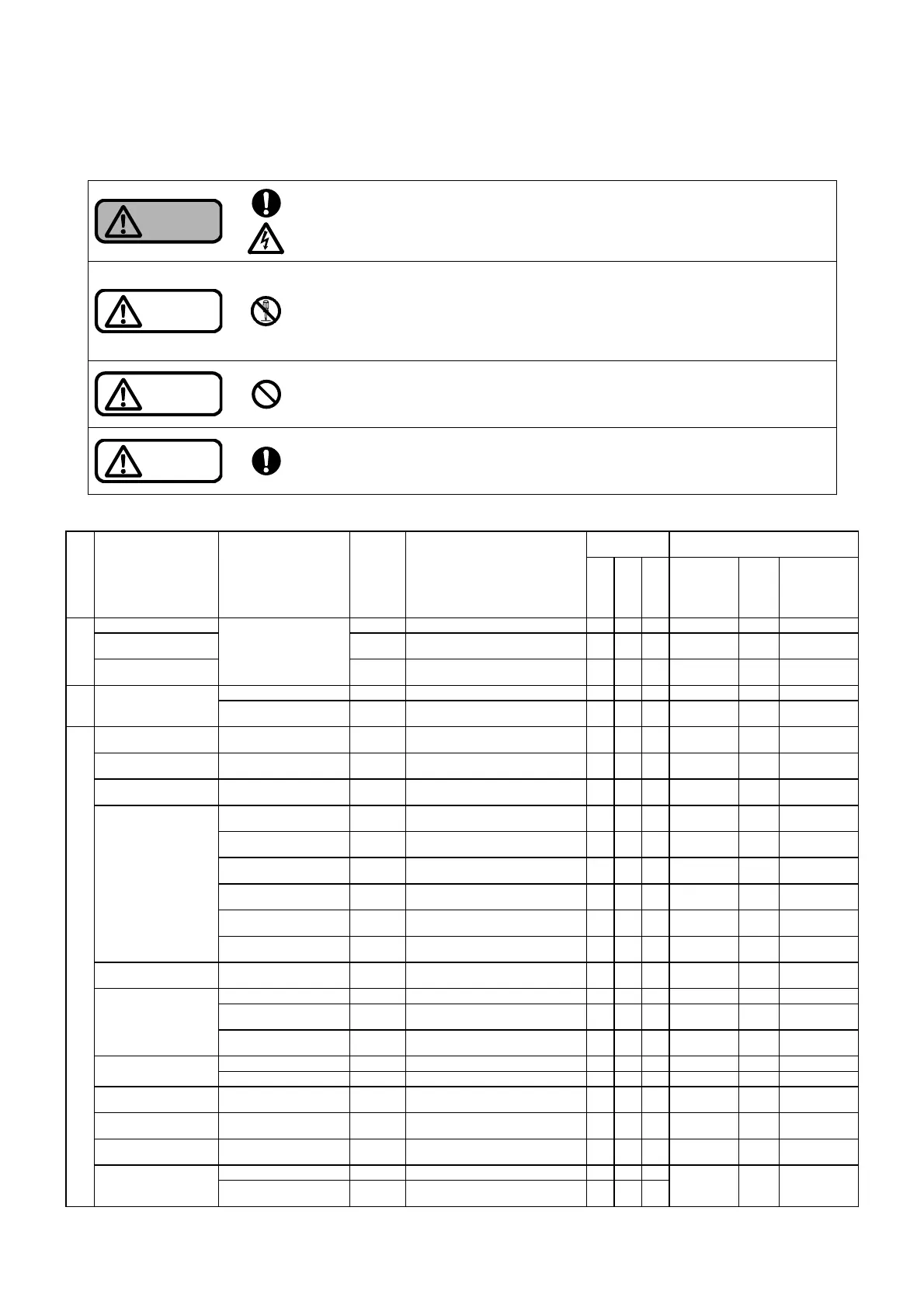

8.3 Maintenance check list

Table 8-3(a) Maintenance check list

Frequency

Consumables

Inspection point Inspection item Method Criterion

Daily

Half-yealyr

Yearly

Part name

Qty.

Replacement

cycle

Temperature

Measure

Between 0 and 40°C

䕿

Humidity Measure

85%RH or less

No condensation

䕿

Ambient

environment

Dust and other

contaminants

Check against the

specified range.

Visual

check

No dust or other contaminants

䕿

Voltage Measure The specified voltage is applied.

䕿

Power

Power terminal block

Voltage fluctuation Measure

Within the allowable fluctuation

range

䕿

Panel display, indicator

lights

Check if they are lit on

Visual

check

No abnormal condition 䕿

Setting values Setting values

Visual

check

As per the requirements 䕿

Operations

Operations in the

automatic mode

Visual

check

No abnormal condition 䕿

Startup pressure

Visual

check

As per the setting value 䕿

Stop pressure

Visual

check

As per the specifications 䕿

Number of starts time of

the unit

Visual

check

400 times or less 䕿

Cumulative operation time

of each pump

Visual

check

Check the adequacy. 䕿

Cumulative number of

starts of each pump

Visual

check

Check the adequacy. 䕿

Operating conditions

Alarm log

Visual

check

No alarms are active.

Check the past alarms.

䕿

Ground fault interrupter Operation point

Visual

check

Not tripped 䕿

Loose screws Tighten Securely tightened

䕿

Trace of heating

Visual

check

No discoloration 䕿

Power supply terminal

block,

Control circuit terminal

block,

Power line

Adhesion of dust, damage

Visual

check

No dust or damage 䕿

Open/close the cover. By hand Smoothly opens/closes

䕿

Cover and its installation

status

Loose connections Tighten Securely tightened

䕿

Structure and

appearance

Insulator

Visual

check

No cracks or deformation 䕿

Inverter Looseness of screws Tighten Securely tightened 䕿 Inverter 1 to 2

Every

5 years

Printed board Operation

Visual

check

No abnormal condition 䕿 Printed board 1

Every

5 years

Noise, vibration Listen No abnormal condition

䕿

Control panel

Cooling fan

Operation

Visual

check

Normal rotation 䕿

Cooling fan 1 to 2

Every

3 years

Warning

Before carrying out inspection that requires disassembly and service, be sure

to turn off the main power supply. Otherwise, it may lead to an electric shock,

and/or causes the pump to start up suddenly in the automatic mode etc., thus

exposing the personnel to great danger.

Caution

Only the service personnel with special knowledge of repairs are allowed to

disassemble the unit. For work such as replacement of parts, repairs, or

inspection that requires disassembly of the unit, be sure to contact a

specialized vendor or the service center specified by Teral. Incorrect work

may cause a failure or accident.

Caution

Do not perform an insulation resistance test on the control panel. Before

performing an insulation resistance test on the motors, remove the wires from

the control panel. Otherwise, it may lead to a failure in the control panel.

Caution

Replace any packing and O-rings during inspection involving disassembly.

Otherwise, it may lead to water leakage.

Loading...

Loading...