3-6

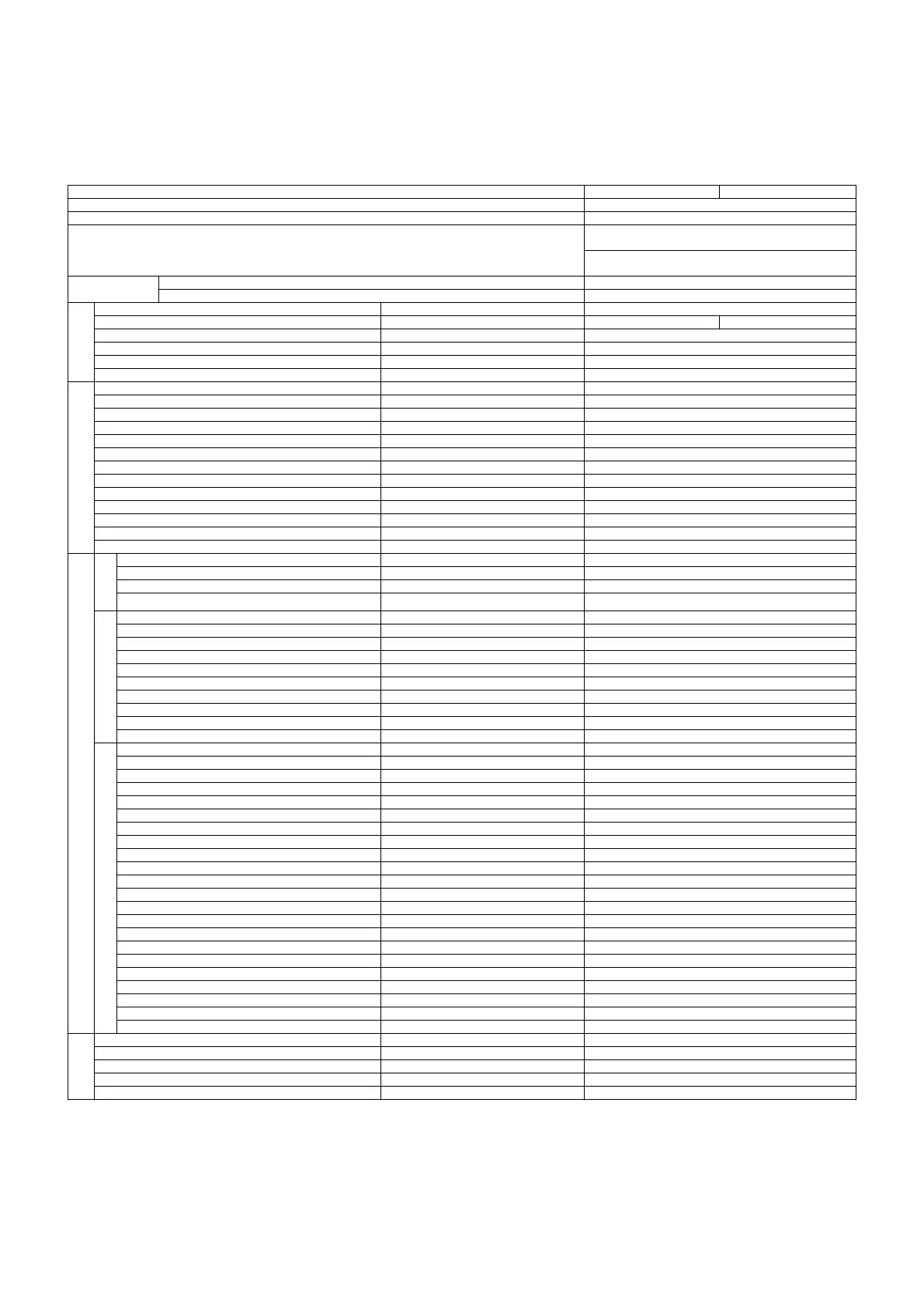

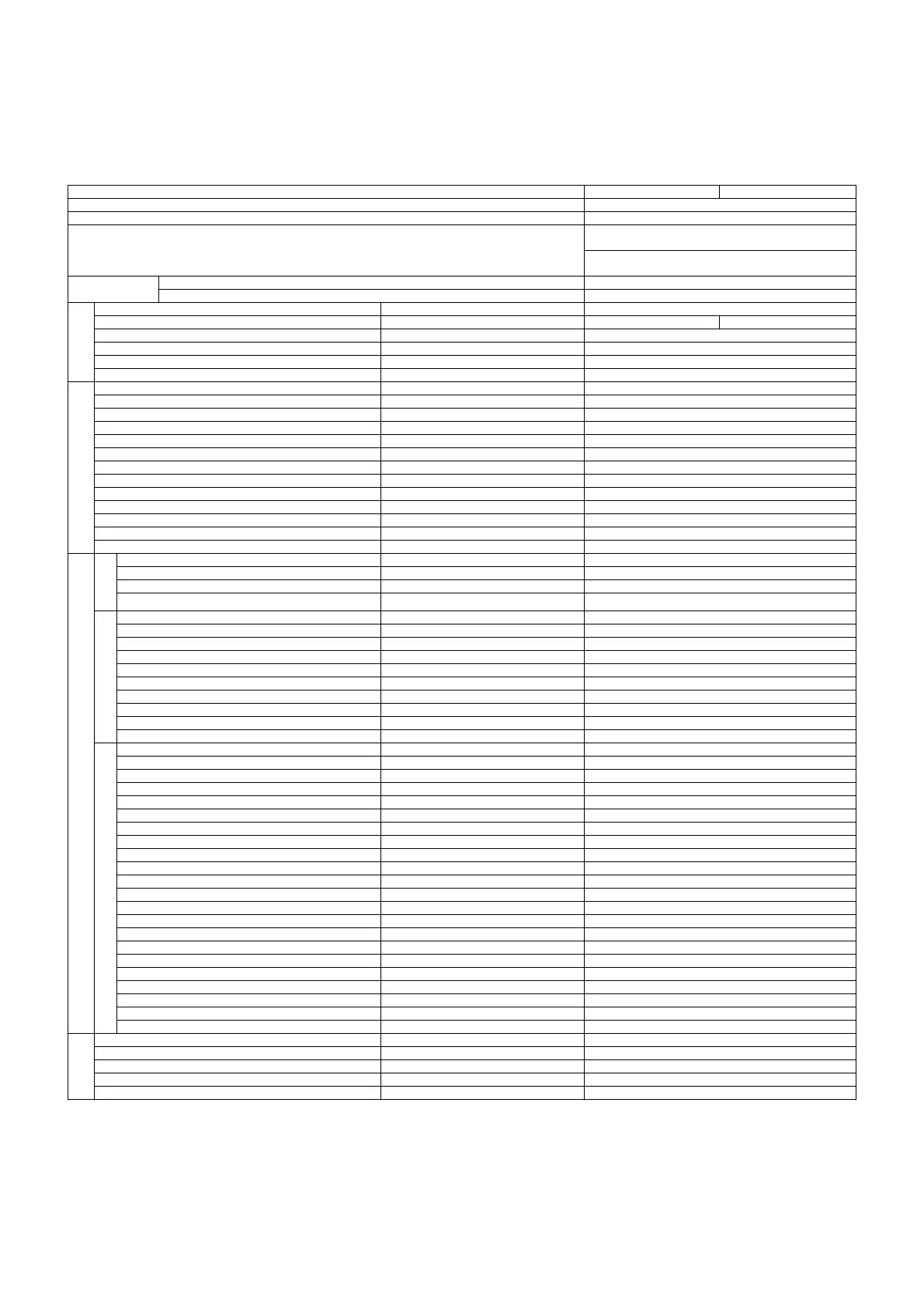

3.3 Specifications of control panel

Table 3-3 Specifications of control panel

Item Specifications 1 Specifications 2

Control panel model BQNXC

Operation mode Automatic alternate/automatic alternate parallel

0.4 to 3.7 kW: ACS resin (light gray/material color) +

steel plate (highly corrosion-resistant hot-dip plating)

Material and external color of casing

5.5, 7.5 kW: steel plate (Munsell 5Y7/1

semigloss/baking finish)

Single-phase 200/200-220 V (50/60 Hz) 0.4 to 1.1 kW

Output Range

Three-phase 200/200-220 V (50/60 Hz) 0.4 to 7.5 kW

Ground fault interrupter Individual pump systems S

Power-factor correcting reactor (DCR) Individual pump systems 㸫 S

Motor protection 㸫 Inverter (electronic thermal protection)

Double receiver tank circuit Can be switched on the operation panel S

Inflow solenoid valve circuit Can be operated on the operation panel S

Circuit

configuration

Electrode 5P circuit 㸫 S

Dry-run prevention 㸫 S

Automatic switching upon failure 㸫 S

Pump continuous operation prevention function 㸫 S

Pump operation time equalization function 㸫 S

Freeze-proof operation function 㸫 O

External stop signal (interlock) available a/b-contact available S

Buzzer stop timer setting 1 to 60 min, , no buzzer S

Full/low water alarm automatic recovery setting 㸫 S

Inflow solenoid valve automatic alternation setting 㸫 S

Inspection mode 㸫 S

Alarm buzzer 㸫 S

Buzzer stop switch 㸫 S

Functions

Energy-saving operation setting 㸫 S

Power 㸫 S

Operation (for each pump) 㸫 S

Block (for each pump) 㸫 S

Indicator

li

h

Alarm (collective) 㸫 S

Discharge pressure Unit: mH

2

O S

Power voltage Unit: V S

Operation current (for each pump) Unit: 0.1 A S

Operation frequency (for each pump) Unit: 0.1 Hz (only automatic) S

Cumulative operation time (for each pump) Unit: Hour S

Cumulative number of starts (for each pump) Unit: times S

Number of starts time of the unit Number of starts on the previous day S

Alarm log 5 latest alarms S

Interlocking in operation 㸫 S

Various indications

Freeze-proofing in progress 㸫 O

Receiver tank full No: E001 S

Receiver tank low No: E002 S

Dry-run prevention No: E003 S

Electrode failure No: E004 S

Start frequency failure No: E006 S

Pressure transmitter 1 failure No: E051 S

Control panel high temperature No: E070 O

EEPROM error No: E080 S

Overload (for each pump) No: E#01 S

Discharge pressure abnormal drop (for each pump) No: E#02 S

Electric leak (for each pump) No: E#03 S

High temperature (for each pump) No: E#04 S

Flow switch failure (for each pump) No: E#05 S

Overcurrent (for each pump) No: E#11 S

Overvoltage (for each pump) No: E#12 S

Anti-stall (for each pump) No: E#14 S

Inverter overload (for each pump) No: E#15 S

Open-phase output (for each pump) No: E#16 S

Inverter overheat (for each pump) No: E#17 S

Inverter communication failure (for each pump) No: E#18 S

Inverter trouble 1 (for each pump) No: E#19 S

Indications on control panel

Alarm indications

Inverter trouble 2 (for each pump) No: E#20 S

Power for alarm Power voltage S

Freeze-proof heater output Power voltage O

Inflow solenoid valve output Power voltage S (Normally open/closed type available)

Operation signal No-voltage a-contact S (for each)

External

output

Error signal No-voltage a-contact S (5 points: patterns 0 to 4)

“S” indicates standard features, and “O” indicates optional features.

*1 Power voltage and operation current values are estimated values. There is an error of approximately 10% with

respect to the full scale.

*2 “E006” and “E#04” can be disabled using settings. Refer to “7.5 Parameter setting.”

*3 The character “#” is replaced by the corresponding pump number.

*4 The open-phase output error is detected by only the units with the rated output of 5.5 kW or more.

*5 For the patterns to output error signals using external relays, refer to “7.5 Parameter setting.”

Loading...

Loading...